Giant Electric Presses Are Key To Productivity Gains at Subaru

Car builder reaps cycle-time improvements and other benefits with large electric presses.

By year’s end, Subaru of Indiana Automotive Inc. (SIA) expects somewhere around 400,000 cars to roll off its manufacturing and assembly line in Lafayette, Ind. They will require 800,000 bumpers, front and rear. And the number comes to nearly 1 million when you count the bumpers the automaker molds for aftermarket service.

While the automotive industry relies heavily on tiered suppliers to furnish parts, components, and sub-assemblies, Japanese-based OEMs tend to prefer making their own bumpers— “the face of the car,” notes Troy W. Castor, an SIA specialist in manufacturing engineering and stamping. The Lafayette facility spreads out to 3.4 million ft2—the equivalent of 58 football fields— with some 33,000 ft2 dedicated to molding TPO bumpers.

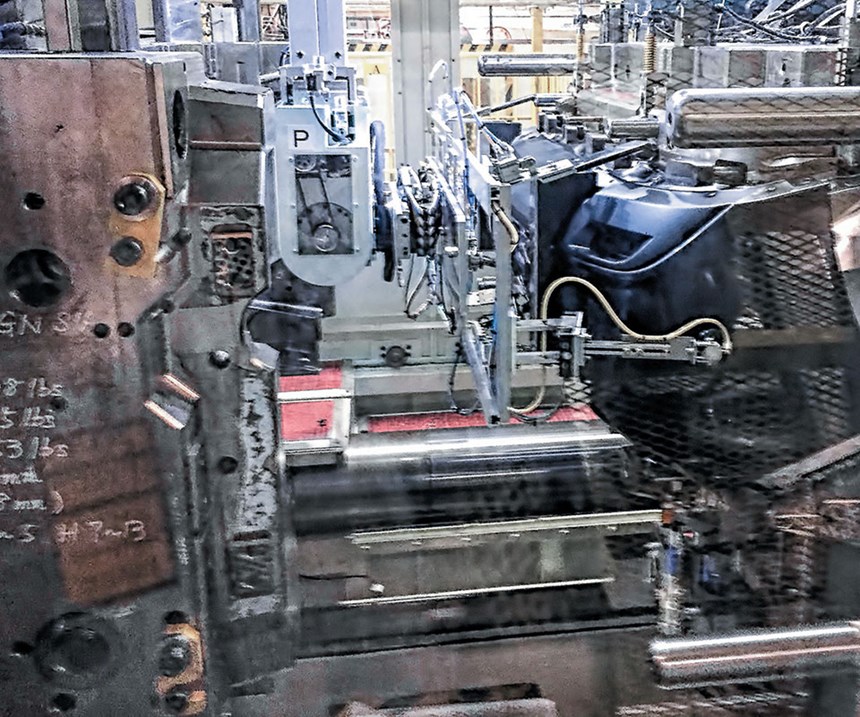

The molding plant is equipped with four injection presses, all from Ube Machinery Inc., Ann Arbor, Mich. Two of these machines are older hydraulic models. Two recent additions, however, are 3850-ton all-electrics, said to be the largest machines of their kind running in the U.S. In fact, Ube has sold 14 all-electric machines of this size to various automotive molding plants in the U.S., notes David Bernardi, the machine builder’s sr. sales and marketing manager.

SIA’s two all-electrics are part of Ube’s UF series. With a maximum shot capacity of 400 oz, the UF3850 units at SIA are built with Ube’s “Box Sleeve” platen design that is said to result in 60% less deflection. Improved ballscrew seals reportedly reduce grease volume by 90% compared with conventional designs. Grease distribution control reduces both grease consumption and ballscrew wear for longer life, according to Ube. The machines’ newly developed “Flex Servo” control is said to provide a more accurate and consistent process. The presses are also equipped with an easy-to- use e-Humma control system and a fully automated quick-mold-change package.

Conventional wisdom holds that higher-tonnage all-electric presses have issues maintaining long hold-pressure cycles efficiently. But SIA, which started running its first all-electric in 2015 and had its second installed this past Christmas, has experienced across-the-board increases in efficiency since it installed the all-electrics. Since it also still runs the two hydraulic machines of similar size, it can make apples- to-apples comparisons between the machine configurations. Notably, the electric presses run cycles of about 43 sec, compared with roughly 61 sec for the hydraulics.

Castor adds, “In terms of efficiencies, we’re seeing less scrap generation with the newer machines. They are cleaner, have required less in the way of maintenance, and offer more efficient mold changes.” SIA has yet to figure out how much it has cut its energy bill by switching to all-electrics, but Castor is confident that “the savings will be there.”

SIA molds bumpers 24:7. It currently has seven active molds, all built in Japan, and makes on average four to five mold changes per machine per shift. The move to all-electrics required the automaker to work with its moldmakers to ensure that the molds are up to the task. Explains Bernardi, “The moldmaker needs to be aware of the capabilities of the machine and make design enhancements accordingly. Speed is a major issue: We could be talking about moving the core in a half-second. The tooling has to be up to the capabilities of the machine.”

At press time, SIA was preparing to fire up its second UF3850, which it will use primarily to make bumpers for its 2018 Legacy sedan. The Ube controllers are set up so that data from one press can be transferred seamlessly to another.

SIA’s relatively recent adoption of all-electric technology in the U.S. came after it conducted internal comparisons of metrics such as cycle time, mold development times, maintenance costs, operational cleanliness, and mold-change times. “Ube did a lot of presentations and we became convinced about the efficiencies of servos and that servo-driven machines represented the future in injection molding,” notes Castor.

Still, SIA is not ready to mothball its hydraulic 3150 and 3300 tonners. “We decide whether to run a bumper on a hydraulic or an all-electric based on a combination of production requirements, machine performance capabilities, and mold-change times,” Castor explains. “Some molds run nearly an entire shift in the same machine without being changed because of current production demand. Also, due to auto-connector/auto-coupler styles, some older molds connect easier to the older machines and likewise the newer molds connect easier with the electric machines. We are in the process of standardizing these differences so it won’t matter as much.”

Castor continues, “We also tend to run the molds that have lower production requirements (require more mold changes) in the electric machines because of the speed they offer during mold-change and startup processes.”

Though it runs non-hygroscopic TPO, the SIA molding operation also includes a new central drying system from Conair, Cranberry Township, Pa. “We dry the material to remove any surface moisture and to ensure that we are delivering material at a consistent temperature to the presses all year round,” says Castor.

Related Content

How To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More