Just for R-PVC: New Gear Pump, Screen Changer

PSI develops its first ever pump, filtration system specifically for heat-sensitive rigid vinyl.

To hear Don Macnamara tell it, rarely does a trade show go by without a least a handful of attendees stopping by the both of PSI-Polymer Systems Inc. asking, “What do you have for PVC?”

At NPE2018 (Booth W5791), the PSI general manager can now play show-and-tell, as the firm is introducing its first-ever screen changer and gear pump specifically for rigid vinyl (RPVC). Target areas for the two new products include sheet and profile extrusions. Generally, the systems can be used on PVC formulations that can tolerate melt temperature variations of 10-15 F.

Says Macnamara, “PVC with little to no stabilizer has a very narrow process window. This material will generally tolerate heat as long as it keeps flowing. If the flow slows relative to heat input, the carbonization process starts and triggers the release of chlorides.”

As he explains it, screen changers are generally not applied to RPVC processes because of flow transitions in the sealing areas exposed to the melt stream. As RPVC travels over these transitions and steps, shear heat is introduced, in turn triggering localized burning of the material.

But PSI has developed a work-around in the patent-applied-for Expansion Plate Screen Changer (ESC), solving “the chemistry issues relative to heat, flow and thermal conductivity” to enable it to be used in PVC processes capable of tolerating those 10-15 F swings in melt temperature.

The screen changer requires a momentary shut down for screen change. This eliminates the need for disassembling the die, which on short runs in particular results in high scrap rates. To change screens on the ESC, the PLC rapidly heats the expansion spacer bars, which separate the body halves above and below the slide plate between the body halves. In the design, the spacers are far from the bore to avoid momentary raising of the melt temperature. The expansion of the spacers pushes the bodies apart, freeing the slide plate to move unimpeded.

Once the new screen pocket is in position and the spent screen is outside the body, shop air or a cooling medium is directed through the spacer plates, cooling and contracting the steel. This effectively shrinks the body halves back against the slide plate, recreating a seal through intimate steel-on-steel contact.

The ESC feature chrome-plated flow bores that are straight-through the screen changer to eliminate hang-up areas. The unit has no mechanical seals, so galling is eliminated. Moreover, the upstream and downstream bodies are identical. These interchangeable halves are field repairable—if a body surface in contact with the slide plate gets scratched, the body can be surface ground by a local machine shop and placed back in service. Components are made from corrosion-resistant stainless steel, says Macnamara. Concerning temperature control, the ESC offers electric heat and air or liquid cooling for the expansion spacers. The bodies are arranged standard with electric heat and can be jacketed for more consistent heat transfer.

Processors of RPVC generally eschew melt pumps as well, according to Macnamara, due to heat generated in the axial clearances of the gears and lubrication zones in the bearings. He states, “While many of today’s pumps are capable of discharging material used for gear and bearing lubrication, maintaining suitably low temperatures over the bearings and gear journals has remained elusive.”

But PSI’s Chlorinated Gear Pump (CGP) is ideal for thermally sensitive polymers and brings all of the die-pressure stabilization, increased output and extruder-pressure reduction benefits of gear pumps to RPVC sheet and profile applications. The new design utilizes modified components and improved heat transfer to reduce temperature excursions that can trigger carbonization/degradation of sensitive materials. The gear pump body and side plates are jacketed for steam or oil heat-transfer media. This media travel through the entire pump in a single pass. Dual-extended gear shafts aid in conductive transference of heat out of the high load areas of the gears. Heat transfers outward from the bearing journals into the cooler seal journals and then through the seals into the jacketed side plates. Seals are contained within and are integral to the side plates for best conductivity. Cooling channels in the body wick heat away from the bearing ODs to control heat buildup Large, jacketed side plates provide additional heat transfer from the bearings

Bleed material used for lubrication of the bearings and gears is evacuated from the process flow via internal ports to outside the pump (approximately 0.01% of flow) in a constant bleed.

Related Content

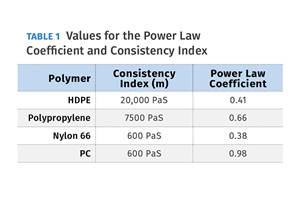

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)