K 2004 Wrap-Up on Additives: Problem-Solving Additives Tackle New and Old Challenges

The latest K show was rich in additives that can ease processing and end-use problems of thermoplastics and thermosets.

The latest K show was rich in additives that can ease processing and end-use problems of thermoplastics and thermosets. Some address long-standing issues, like warp age induced by organic pigments, taste trans fer from plastic packaging to foods and beverages, and uv stabilizers that cause irritating dust or pigment interactions. Some new additives are geared to more recent concerns, like ammonia smell from non-halogen intumescent flame retardants, coupling and dispersion problems in wood-fiber composites, and higher heat exposure from non-lead solders for electronic assemblies.

'Friendly' intumescent FR

A cost-effective, non-halogen, intumescent flame retardant for PP and other thermoplastics is new from Great Lakes Chemical. Reogard 2000 is said to eliminate ammonia odors and "milky" water baths that can occur during extrusion with other intumescent FRs. It is also said to yield UL 94 V-0 PP at lower loadings than other FR systems (20% vs. over 28% at 1/16 in.) and to provide higher impact and HDT. It can also be compounded at lower temperatures because it is partially melt blendable.

New light stabilizers

Great Lakes Chemical came out with a nickel-based uv stabilizer system in a dust-free granular form for PE agricultural films. Lowlite Q21 is a No Dust Blend of Lowlite Q84 nickel quencher and Lowlite 22 uv absorber. Besides eradicating asthma-inducing dust associated with nickel quenchers, it has a lower melting point, which provides much easier dispersion.

Also new from Great Lakes is Lowlite 19, a monomeric HALS that has low interaction with pigments in polyolefins. Its high molecular weight provides low volatility plus migration resistance. It also acts as an antioxidant that adds long-term heat stability.

Clariant Corp.'s Pigments & Additives Div. has a new uv absorber for engineering thermoplastics. A benzylidene-bis-malonate, Hostavin B-CAP is colorless but acts as a physical screen that absorbs high-energy uv rays. It is said to cause less discoloration than other uv absorbers, even in extreme climatic conditions and demanding applications like auto headlamp lenses. Hostavin B-CAP can be combined with other stabilizers for long-term protection of PC and PET.

Don't taste the plastic

Wacker-Chemie GmbH in Germany (parent of Wacker Silicones) introduced Cavamax natural cyclodextrins that can be added to bottle caps or other packaging. They protect foods or beverages from off-tastes introduced by the plastics. Cyclodextrins consist of glucose sugar molecules linked into a cylindrical basket that traps organic molecules such as aldehydes.

Functionalized olefins

A new family of Priex adhesive-functionalized polyolefins has been developed by Solvay Plastics in Brussels, Belgium. They will be marketed here by Solvay Engineered Polymers. Priex consists of two series intended as easy-flowing additives for PE and PP. The first is PP and HDPE grafted with maleic anhydride (MA) by reactive extrusion. These grades are for use as adhesion promoters for metal pipe coating, dispersion aids, compatibilizers, and coupling agents for glass or wood fibers. (Aqueous emulsions—said to be a first—are available for precoating wood fibers.)

Another potential use is in auto fuel tanks: Mixed into conventional HDPE, Priex MA-grafted HDPE reportedly confers good adhesion to an EVOH barrier layer. Because Priex migrates to the layer interface, there is no need for a separate tie layer, and gas tanks could be made with three layers instead of five, according to Solvay. Priex also boasts higher purity and stability than competing resins. It has less free MA (guaranteed <100 ppm), reportedly providing better performance and/or enabling lower use levels.

The second Priex series comprises ionomers of HDPE, PP homopolymer, and PP random copolymer. They improve mechanical and thermal properties of standard PP and HDPE, and also enhance adhesion. Just 2.5% to 5% Priex ionomer reportedly boosts HDT, creep resistance, stiffness, and impact. Unlike other ionomers, Priex is not highly crystalline and is thus easier to disperse in polyolefins, says Solvay.

Meanwhile, Crompton Corp. is developing improved coupling agents that will confer better mechanical properties to wood-filled composites. The company is working on a new grafting process that will allow production of HMW PP with high levels of maleation—something that reportedly could not be done with conventional reactive extrusion methods. Crompton is developing an in-reactor grafting technique similar to its Interloy reactive alloying process. Now in the advanced pilot stage, the process is expected to produce commercial product by the end of the year.

Lotader AX8950 is a new epoxy-containing ethylene-acrylate terpolymer that promotes adhesion of overmolding compounds and polyolefin foams to nylons, TP polyesters, steel and aluminum. It can also be used as a compatibilizer and impact modifier for engineering thermoplastics, especially polyesters. It is said to promote high flow for injection molding. Lotader comes from Arkema (formerly Atofina).

Multi-functional waxes

Clariant's Pigments & Additives Div. recently broke ground in Frankfurt, Germany, for the world's first plant to produce polyolefin waxes by metallocene catalysis. When completed later this year, the plant will have a capacity of several million pounds. Clariant says its unique process allows fine-tuning hardness, melting point, viscosity, molecular weight, and compatibility with various polymers. These "designer" metallocene waxes were first announced at K 2001. Three new grades were announced at K 2004:

Licocene PP 6102 is said to significantly improve pigment dispersion in PP, including the hard-to-disperse pigment Yellow 155 and Red 48:2. It is particularly suitable for films or fibers.

Licocene PE MA 4351 is a PE wax grafted with maleic anhydride to compatibilize PE and natural fibers.

Licocene PE MA 4221, another MA-grafted PE wax, is a colorless multifunctional lubricant specially developed for color-sensitive applications in nylon, PBT, and PET. It promotes flow and mold release and is said to be more heat-resistant than competitive products (up to 250 C, 480 F) and less prone to yellowing.

Licocene PE 4201 is a nucleating agent for EPS that is said to provide homogeneous cell structures for optimum foam properties.

Non-warping colorants

Ciba Specialty Chemicals introduced another non-warping pigment in addition to the two reported in our September show preview. Cromophtal Red PD 3092 is the first of a new generation of DPP pigments for plastics. It is a yellowish red said to combine transparency with unique saturation plus outstanding color strength and heat stability in polyolefins and PVC. It can be combined with Cromophtal Red 2030, an opaque DPP pigment, to tailor the transparency/opacity of colors.

Clariant's Pigments & Additives Div. introduced its first two DPP pigments. Both are Pigment Red 254 types. PV Fast Red D 3G is a mid-shade red that's particularly suited to polyolefins and food packaging. It is also offered in a non-dusting and free-flowing form (DrizPearls Red D3G). The other product is Hostaperm Red D2G 70 for exterior applications.

Also new from Clariant is PV Fast Yellow H2GR, a Pigment Yellow 191. This highly stable monoazo calcium lake is described as an economical, brilliant mid-shade yellow with high color strength, excellent fastness, and high transparency.

Clariant also improved the dispersability and color strength of five Graphtol red pigments for economical coloration of polyolefin films and PP fibers—Red P2B, Red WTP, Rubine 6BP and GDP, and Fire Red 3RLP.

Eckart GmbH introduced Aloxal, a new class of aluminum pigments. The "champagne" basic tone reportedly produces strong, warm metallic colors and opens up an extended color spectrum. Also new are Phoenix pearl-effect pigments that range from silver-white and interference colors to earth tones and combination gold colors.

Degussa's Coatings & Colorants unit introduced a line of liquid colors under the name Polytrend 700.

New pigment blacks from De gussa's Advanced Fillers & Pigments unit are "SQ" versions of standard Printex alpha, L, and L6. Extra particle-size control is applied to suit these pigments to fibers and thin films.

Newly available worldwide is Degussa's Hiblack 420 B, a conductive carbon black for cables and semiconductors. It is fine-tuned for dispersibility, conductivity, and high purity.

A new dispersion aid for making color concentrates is Tegomer P 141 from Degussa's Goldschmidt Industrial Specialties. It was developed specifically for coloring PP parts and microfibers.

BYK-Chemie has three new wetting and dispersing aids for making color masterbatches. The Disperplast series of highly functionalized copolymers are not comparable to standard waxes or metal soaps, according to the company, as they do not act as lubricants but adhere to the pigment surface. Grade 1010 is for masterbatches used in cast film and thin-wall moldings, where it is said to provide enhanced color strength and permit reduced pigment loadings. Grade 1011 is said to reduce filter pressures in extruding blown film and fibers. Grade 1012 optimizes throughput in injection or blow molding.

Nucleator and clarifier

Great Lakes Chemical has expanded its new line of nucleating and clarifying agents with Anox Clearlite NU 011, an organophosphite ester. The company entered this field last March with micronized sodium benzoate and sorbitol-based nucleators and clarifiers. NU 011 nucleator and clarifier is said to be easily dispersible and highly effective even at low concentrations in PP, PET, PBT, and nylon.

Flow & impact modifiers

Two new families of silicone modifiers for thermoplastics and thermosets were showcased by Wacker-Chemie. For thermoplastics, Genioplast Pellet S is silicone gum in a new pellet form designed for automated handling. It is UHMW silicone in a universal silica-based carrier matrix. The pellets reportedly carry a higher silicone concentration than has been possible before. Genioplast Pellet S acts as a processing aid and flow enhancer. It also improves scratch and abrasion resistance and impact strength. Genioplast has been tested in LDPE, HDPE, and PP and is said to be especially helpful in filled PP. Uses include cable jacketing and automotive molding.

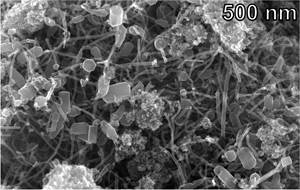

Second, Wacker's new Genioperl additives confer low-temperature toughness, scratch and abrasion resistance, and weatherability to thermoplastics and thermosets. These nano-particles have a core of crosslinked silicone elastomer surrounded by a thermoplastic shell that adds compatibility. Genioperl is supplied in an easy-to-handle granular form that readily breaks down into the original nano-particles. Genioperl has been used in acrylic compounds for auto side mirrors and spoilers. A version containing elastomer particles with a heat-resistant polyacrylic shell is said to enable epoxy microelectronic encapsulants to withstand lead-free soldering at 250 to 260 C (480-500 F).

Wacker is also working on new developments in its Vinnapas polyvinyl acetate (PVAc) low-shrink/low-profile additives for thermoset polyester molding compounds. Versions may become available this year that provide higher strength and better pigmentability.

A new reactive impact modifier for PBT is Degalan IM 2MD from Degussa. Aimed at unreinforced automotive applications, this acrylic modifier has reactive groups that bond to PBT, improving compatibility and providing good toughness and flowability.

In the past year, Crompton came out with two new EPDM grades for use in PP thermoplastic vulcanizates (TPVs). Royalene 694 and 4697 are high-MW grades extended with a new white paraffinic oil. They are said to be much more gel-resistant than older, dark EPDM grades and are suitable for colors other than black.

PVC additives

A new proprietary family of high-performance specialty lubricants is said to speed extrusion of PVC by 20% to 40%. Honeywell Specialty Additives aims these Rheochem products at PVC window and door profiles, fencing, pipe, and siding. RLX 820 and 860 are designed for tin stabilizer systems, and RLX 805 and 880 for Ca/Zn systems. These lubricants reportedly increase production rates by improving control over melt viscosity, melt temperature, and heat stability. They are cost competitive with other high-performance lubricants but work even better, Honeywell claims. Lab and field test results show that they allow a 20% to 25% reduction in heat-stabilizer levels.

Tyrin 7000 and 2500 are two new chlorinated polyethylene (CPE) impact modifiers from DuPont Dow Elastomers that reportedly offer broader processing windows and lower costs in PVC window profiles, siding, fencing, and specialty pipe. Unlike other CPEs, Tyrin 7000 can be handled in bulk. (It supercedes Tyrin 6000.) Tyrin 2500 reportedly offers faster fusion and lower density.

Also new from DuPont Dow is Enlite, a developmental family of very low-density elastomers based on a new type of modified CPE with unusually low chlorine content. It is for PVC window profiles, siding, pipe, and electrical connectors. Typical use levels (3% to 3.5%) are 17% lower than for standard CPEs.

BYK-Chemie has introduced two nano-alumina additives to improve scratch and wear resistance of uv topcoats on PVC floor coverings. Nanobyk-3600 is a water-based dispersion and Nanobyk-3601 is a dispersion in tripropylene glycol diacrylate.

Upgrade recycled PET

Four new modifiers that boost properties and processability of R-PET were introduced by Kaneka of Japan. Two impact modifiers are Kane Ace M-400 acrylic type and M-600 MBS type. The acrylic version is outdoor weatherable, but the MBS grade is a more efficient modifier. They toughen other engineering plastics, too.

Two reactive acrylic processing aids are Kane Ace MP-20 and MP-40. They raise the viscosity of R-PET by producing partial crosslinking. The resin can then be injection molded, blow molded, and extruded into profiles, tubing, thin sheet for thermoforming, and even blown film. Use levels are 0.5 to 3 phr. MP-20 yields opaque products, while MP-40 leaves them clear. Injection molding applications include a 90-liter trash bin, pallets, and chairs. These products are said to work synergistically with the new impact modifiers. Raising the melt viscosity yields a finer dispersion of the impact modifier, enhancing its effectiveness, according to Kaneka.

Silane coupling & curing

New developments for crosslinked PE pipe and cable were shown by Degussa's Aerosil & Silanes business unit. Dynaslan Silfin 63 is a three-component silane system for low-voltage cable insulation. It uses peroxide to achieve much higher curing speeds than standard mixtures, and it also reportedly does not cause odor problems.

Two other silane-based systems are designed for halogen-free cables loaded with hydrated mineral fillers. Dynaslan Silfin 70 and 71 are ready-to-use, single-stage, moisture-curing systems that need no peroxide.

There's also news in silane coupling agents. Wacker-Chemie has come out with Geniosil a-silanes that replace the standard propylene "bridge" between the silicon atom and the functional group with a shorter methylene bridge. This greatly increases reactivity and reportedly provides better coupling of fillers and reinforcements, which translates into higher mechanical properties. Though a-silanes are more expensive, smaller amounts can be used. Also, their high reactivity makes possible entirely new applications, such as making polyurethanes without isocyanates.

The news from Dow Corning is not a new product but a new effort to capitalize on its silane technologies. The company has had limited exposure to the merchant market because it has used most of its silanes internally. It decided in 2000 to focus more on providing a full line of silanes to the external market. Last year, Dow Corning opened the Surface and Interface Solutions Center (SISC) in Seneffe, Belgium. This global R&D center will exploit the firm's three core competencies—adhesion (including plastic-to-plastic adhesion in overmolding), filler modification, and reinforcement sizings. "We want to offer more complete solutions—a new type of composite or process, not just a silane," says Thierry Materne, global technology and business development manager for silanes. He expects much of the SISC's effort to be devoted to working with customers to develop tailor-made approaches.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Loads of New Additives and Colorants to Debut at K 2004

Several categories of new polymer additives will be unveiled at this year’s largest plastics show—K 2004 in Dusseldorf, Germany, next month.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)