Laser Scanning Pinpoints Shrinkage Problems in Record Time

A faster way to measure part surface dimensions helped injection molder Hy-Ten Plastics to quickly identify and correct geometries in its tooling that spawned problem parts.

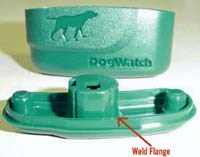

A faster way to measure part surface dimensions helped injection molder Hy-Ten Plastics to quickly identify and correct geometries in its tooling that spawned problem parts. Hy-Ten, a $5-million/yr company in Milford, N.H., is no stranger to challenging molding projects, yet it needed help to deliver one project on time. The company molded parts for a dog-collar signal-sensing system sold by DogWatch of Natick, Mass. The DogWatch System 3000 consists of a small electronic device that hangs from a dog collar and emits an FM signal to stationary receivers. An alarm sounds when the dog-collar emitter passes a receiver. The system creates a “hidden fence” for the dog.

Shrinkage problems

Two-piece housings for the dog-collar transmitter and the signal receiver are molded by Hy-Ten using a high-flow polycarbonate. The challenge was in producing the four-parts in a 2 x 2 family mold. The critical requirement was a very precise interference fit between each of the molded halves, which would be ultrasonically welded together to provide a water-tight seal around the electronic components. “The geometry of the parts was so complex that the parts shrank in a very non-uniform and hard-to-predict manner,” says Craig Heinselman, quality-assurance manager for Hy-Ten.

Irregular shrinkage caused the prototypes to fit together unevenly. “Because of the complex 3D geometry, the only way to design the mold was to guess at the shrinkage, build the mold, and measure the parts,” Heinselman said.

Through early trials Hy-Ten had eliminated the material, mold cooling, and process parameters like fill times and speeds and packing pressures as sources of the problem, so that narrowed the focus to the design of the core or cavity.

The CAD/CAM software that Hy-Ten uses for part and mold design couldn’t provide enough help on how to correct the problems, and flow-simulation only gave an estimation of the deviation of the part dimensions due to shrinkage. “We needed to know the degree to which the part actually deformed,” says Heinselman.

To solve such a problem, Hy-Ten would usually employ a coordinate measuring machine (CMM) to “map out” the shape of the parts by measuring positions on the part surface point by point. That surface map would then be compared with the “ideal” part dimensions specified in the CAD model, and the differences would give insight on where and how much to adjust the core or cavity dimensions. “Yet when you are dealing with a complex 3D contour, you often need millions or tens of millions of points to get the geometry exactly right. We could have easily spent several weeks generating the points on the parts, and even then we would not have been sure that we didn’t miss points that were necessary to get an accurate surface model,” says Heinselman.

The other big problem was time. Hy-Ten had promised its customer that part samples would be delivered for their review and approval within a month. This left too little time to generate the CMM plot, analyze the part differences, send the suggested mold changes to the tool maker, and then get the mold back to produce parts.

Laser scan to the rescue

Hy-Ten enlisted the services of Laser Design, a Minneapolis service bureau that uses laser scanning to map part geometry. Laser Design took just five days to create a surface model of each prototype part that was accurate to 0.001 in., and to map it onto the original part geometry, creating an “error map.” The error map made it easy to modify the mold so that the final parts shrank to the correct size and shape. It took the tool maker just nine days to adjust the tool based on the error map, and six more days for Hy-Ten to produce the new sample parts. “What had taken 20 days would have taken months of expensive trial and error using conventional means,” says Heinselman.

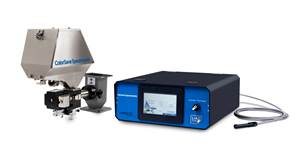

Laser Design employs a non-contact, low-power diode laser system to measure the parts, says Larry Carlberg, engineering service bureau manager. The system casts a laser beam across a surface and picks up or assigns anywhere from 15,000 to 50,000 points per second. The laser can plot 10 million to 20 million points, but an accurate analysis requires only 1 million to 5 million points. “A part that is 6 in. square can be scanned on both sides in 15 to 25 minutes and be accurate to ±20 microns,” says Carlberg.

The points are transmitted to a software package from Raindrop Geomagic of Raleigh, N.C. The Geomagic Qualify software generates the detailed dimensions of the part and compares them to the original CAD design. It creates a color map that shows the deviation of the part surfaces between the two sources. “Laser scanning delivered higher-quality parts in a fraction of the time of CMM and helped us determine precisely how the prototype differed from the design intent,” says Carlberg.

Once Hy-Ten received the color map from Laser Design, it sent the suggested changes to the mold maker, Concept Tool and Die in Goffstown, N.H.

A laser scanning system and software would cost around $115,000 to $150,000, says Carlberg. A portable laser probe that is retrofittable to a CMM machine would cost around $60,000. However, Laser Design’s service cost around $600 for each part scan (price varies with part design and number of plot points required), including an inspection report.

Related Content

Handheld NIR Instrument Distinguishes PET from PETG

Mobile spectroscopy from trinamiX detects more than 30 different plastics—and now PET vs. PETG as an aid to recycling.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreColor-Measurement for Extrusion, Molding

System helps processors control the cost of quality due to color variations, using real-time color data for QC analytics and color optimization.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)