‘Lean’ Molding & Liquid Color: A Good Fit

If you want to take up parasailing, it’s probably best that you have no fear of heights.

If you want to take up parasailing, it’s probably best that you have no fear of heights. If you want to go where few if any large-part blow molders have gone before, it’s probably best if you have no fear of failure.

Such was the mindset of Hayward Pool Products, Clemmons, N.C., which injection and blow molds a wide range of pool products. In 2008, the molder switched from using pellet concentrates to liquid colors on three large blow molding machines producing housings for filter tanks, a move considered risky by most blow molding pundits.

The switch to liquid color, supplied by Riverdale Color Co., Perth Amboy, N.J. (riverdalecolor.com), is among the more recent changes made by Hayward as part of an ongoing process that started in the late 1990s to streamline its manufacturing processes. “Before 1999, we were a typical U.S. manufacturer,” remarks Scott Pugh, Hayward’s heat-pump and filter manufacturing manager. “Production was not tied to demand. We were overproducing, had inventory everywhere, and needed more space just for storage.”

Hayward worked with consultants and in late ’99 revamped its operation to incorporate “lean” manufacturing techniques advanced by the likes of Toyota years before. To go lean, Hayward had to revamp its processing operation entirely—no small feat when you consider the thousands of different parts of all sizes it molds and welds. Gone were the long assembly lines, replaced by U-shaped manufacturing cells where components are injection and blow molded and assembled into complete parts by one operator.

The desire to produce products on demand and reduce inventory also encouraged Hayward to replace more traditional dry colorants with liquid. “As we went lean, we had to make shorter runs of multiple products, and respond quickly to demand,” Pugh explains. “With dry color, the time it took us to change over was posing a huge problem. We’re talking about cleaning a huge accumulator head weighing 50,000 lb. You can’t take it apart, material tends to hang in there, and it was taking us up to 25 hr just to switch from one color to another.”

As part of its continuous-improvement initiative, Hayward assembled a project team to look at every aspect of the problem…more than once. “Our culture encourages us to try things and not be afraid of failure,” states Pugh. “We knew that in order to even try to run liquid, for example, we had to rebuild our screws, which cost us $70,000 on the three blow molders. But we made the investment before we even had an inclination of the result.”

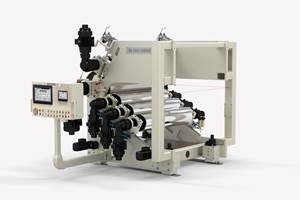

After several trials, involving multiple liquid-color vendors, different formulations, and machine modifications, Hayward went with Riverdale’s Pump-in-a- Drum liquid color system combined with a weigh-scale blender furnished by Riverdale sister company Maguire Products, Aston, Pa. (maguire.com). Pugh summarizes the benefits:

- Huge reductions in scrap due to color changes. A black-to-platinum switch used to take 300 parts to finish. Now it takes fewer than 20.

- Faster changeovers, resulting in lower inventories yet improved customer deliveries.

- Elimination of landfill-bound purgings.

- Lower storage space requirements than for pellet colorants.

- Reduced cycle times.

- Ability to reuse liquid containers.

- Reduction in regrind fines.

“It took persistence to bring liquid color use to fruition at Hayward,” Pugh says. “A culture of continuous improvement provided us with a foundation to move forward.” Pugh says the results have been so impressive that Hayward is mulling a move to liquid for injection molding as well.

Related Content

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

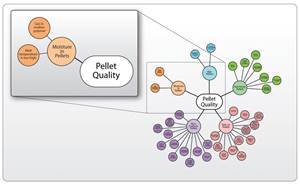

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More