Mold Analysis Gets Faster, Easier, Smarter

On Dec. 28, Moldflow Corp. began shipping a major new release of its flagship injection mold simulation software, Moldflow Plastics Insight 6.0.

On Dec. 28, Moldflow Corp. began shipping a major new release of its flagship injection mold simulation software, Moldflow Plastics Insight 6.0. MPI 6.0 is engineered to work much faster, be easier to use, and provide more useful information than before. Many of its enhancements are directed particularly at analyzing thick, solid parts—or thin parts with localized thick sections—using the MPI/3D module, which employs 3D solid-geometry mesh elements. Some of these new features will later be extended to more typical thin-shell plastic geometries that utilize conventional midplane analysis or Moldflow’s proprietary “Dual Domain” surface-mesh technique, supplied in the MPI/Fusion module.

MPI 6.0 also enhances speed and accuracy in analyzing conventional thin-shell parts—for example, in predicting fiber orientation in reinforced parts. There are also improved capabilities for analyzing very thin parts—less 1 mm—which are becoming more common. And the materials database has been expanded with hundreds of new materials and thousands of updates to materials properties.

In recent months, Moldflow also came out with enhancements to its simpler, faster, lower-cost Moldflow Plastics Advisers (MPA), and to other software products for CAD integration.

Faster 3D analysis

Much faster 3D analyses come from a new “coupled 3D flow solver” in MPI 6.0. The older solver offered users a choice of “Fast” or full Navier-Stokes calculations, the latter being slo wer but more accurate. The new coupled 3D flow solver gives only full Navier-Stokes solutions up to 800% faster than before and is even 34% faster than the previous “Fast” analysis.

A number of other 3D flow improvements also result:

- Flow-front advancement can be calculated in larger time steps to gain speed without sacrificing accuracy.

- Shear-heating calculations are said to be more accurate, especially at points where shear changes rapidly along the flow path, such as near a gate and in flows around corners.

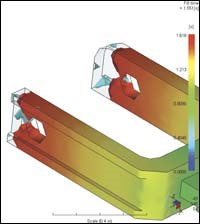

- The new 3D Warp solver can calculate warpage of 3D parts an average of 7 times faster. Additional time savings are available from the new ability to use a “coarse-through-thickness” mesh to simplify warp models. This can make calculations up to 35 times faster.

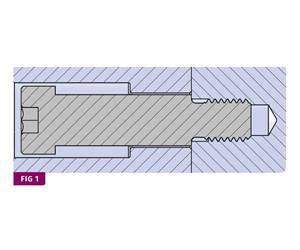

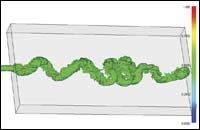

Apart from speed and accuracy improvements, MPI 6.0 provides some previously unavailable information. Moldflow says this is the first software ever to simulate the “jetting” phenomenon when melt first enters a cavity, which tends to be more of a problem in thicker parts. This software advance could be helpful in designing automotive lenses, where jetting of the initial flow through the gate can cause visible defects.

Also new is the ability of MPI/3D to predict partial remelting of the interface zone during overmolding of one plastic with another. This alerts the user to the possibility of smearing the first material into the second. This result is currently available only for 3D analyses.

In addition, MPI/3D now can predict air traps. This feature was previously available for thin-shell models, but 3D analysis can reveal air pockets deep within parts as well as on the surface. MPI/3D can now simulate gas assist much faster through use of 1D beam elements instead of solid elements in runners and overflow wells. (Gas-assist simulation is already available for thin-shell models.)

MPI 6.0 also can aid shop-floor troubleshooting by importing data on actual molding machine characteristics, process settings, and process variations from Moldflow Plastics Xpert (MPX) or Shotscope monitoring systems. This allows a simulation to be run with “real-life” conditions.

- MPI 6.0 can also export hot-runner temperature settings and layouts to Moldflow’s Altanium Matrix process controller, which displays graphic diagrams of the hot-runner system.

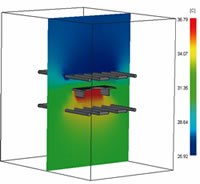

- MPI/3D provides new flexibility to display the temperature distribution throughout any cross-section of the mold. This profile of steel temperatures can help optimize cooling-channel layout. (Thin-shell analysis has a more limited capability of this sort.)

- MPI 6.0 can now isolate the causes of warpage for 3D parts as it already does for thin-shell models. It can calculate deflections due to unbalanced cooling, non-uniform shrinkage, and fiber orientation, in addition to the total deflection. In addition, thin-shell simulations have a new ability to isolate warpage due to corner effects.

- Previous ability to calculate core shift has been enhanced with new calculations of stresses on the cores to give insight into core fatigue before actual cracking occurs.

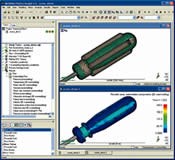

Easier & more flexible

In MPI 6.0 the user interface for all types of analyses has been reorganized for greater convenience and less screen clutter. For example, modeling and meshing tools, which formerly opened in windows on top of the model, now have been moved to panels on the left side of the screen, so as not to obscure the view of the model. Also, the modeling and meshing tools have been consolidated into a graphical Toolbox that avoids the need to pick through menus, and the Project and Study panels are merged into a new Tasks tab. All textual log windows have also been consolidated into one. And now, a single mouse click hides all panels to leave the entire screen free to display the model.

Evaluation of models is faster and easier with a new system of “directed diagnostics.” Diagnostic warnings about meshing problems are now prioritized by degree of severity, and when a problem is selected, the model automatically orients itself to give the best visibility of the problem mesh elements, which are also highlighted.

The system now also automatically identifies isolated, extremely large elements for correction, and the auto-fixing function is extended to correct collapsed areas of the mesh.

Another new ability is local mesh refinement in MPI/3D to increase or decrease the number of layers of elements in a specific area of the model (as already can be done with thin-shell models). Before, 3D analysis allowed users only to increase or decrease the size of elements in the layers.

Now it is also possible to generate analysis reports in Microsoft Word or PowerPoint formats in addition to html.

Faster, simpler, smarter

In September, release 7.2 of Moldflow Plastics Advisers (MPA) added new capabilities to this simplified, easy-to-learn product for preliminary analysis of molding feasibility. One of the main new features is the Advanced Geometry Adviser, which checks a newly constructed model and suggests ways to improve it before starting the analysis. It can identify thick, solid regions that could be thinned to reduce molding cycle time and material cost, thin areas that would retard flow, and cosmetic features such as fillets and text that could be removed from the model because they do not have much effect on analysis results but increase analysis time.

Faster analysis is also possible using a new Naturally Balanced analysis mode. This mode allows you to select a naturally balanced runner system from a library of commonly used layouts. You can then edit the properties of specific runners, if necessary. Analysis is performed on a single highlighted cavity and results are extrapolated to the entire layout. Filling and packing analyses thereby take much less time than a full analysis in standard Multi Cavity mode. In addition, the new release lets you import centerlines of complex or curved runners from a CAD file in IGES format.

The Cooling Circuit Adviser includes a new Cooling System Wizard that helps create cooling circuits more efficiently than before. With the new wizard, you can set channel diameters, distance above and below the parting plane, number of channels, distance between channels, and distance to extend hoses beyond the mold. You can also assign properties to multiple cooling lines at once and specify the cooling inlet location.

MPA 7.2 also reveals not just the location of weld lines and air traps, but the relative seriousness of these defects. It does so by presenting the details on flow-front temperature, pressure drop, injection pressure, and fill time when these defects were formed.

New CAD tools

Two other new updates last September were Moldflow Design Link (MDL) 5.2 and CAD Doctor 2.0. MDL allows direct import of solid geometry data from leading CAD systems into MPI and MPA. MDL 5.2 has updated interfaces to the latest CAD releases of Parasolid, SolidWorks, and Catia.

Moldflow CAD Doctor checks, corrects, and “heals” solid models imported from popular 3D CAD systems in preparation for analyses using MPI and MPA. Version 2.0 has a new interface to MDL to import data from Catia V5, Parasolid, Pro/Engineer, SolidWorks, and STEP formats (vs. just Catia V4 and IGES before).

Related Content

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)