Novel Melt Blending Technology Commercialized in Micro- and Nanolayer Films

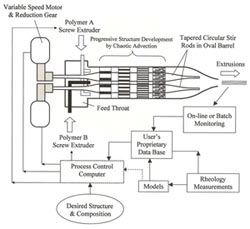

The first two commercial devices have been installed to melt blend two or more polymers using a structured fluid-dynamic mixing process known as “chaotic advection.” This process creates unusual micro-scale and nano-scale phase morphologies that potentially can optimize extruded film properties using fewer materials and extruders than with highly layered coextrusion.

The first two commercial devices have been installed to melt blend two or more polymers using a structured fluid-dynamic mixing process known as “chaotic advection.” This process creates unusual micro-scale and nano-scale phase morphologies that potentially can optimize extruded film properties using fewer materials and extruders than with highly layered coextrusion. The technology can thus replace complex feedblocks and multi-layer dies and eliminate need for costly tie-layer resins. What’s more, it can change from one extruded structure to another simply by adjusting the rotation of “stir rods” in the barrel. It is also possible to create films or other extrusions with special properties such as electrical conductivity or additive-release characteristics.

The mixing systems are built by Smart Blending Technologies LLC in Clemson, S.C. They consist of a “smart blender,” touchscreen control panel, and process-control software. Both systems were built for product development—one for cast film and one for blown film, although similar “smart blending” machines could also be used to extrude sheet, tube, and even fiber, the company says.

Smart Blending Technologies was founded three years ago to commercialize the technology by its inventor, Prof. David Zumbrunnen of the Dept. of Mechanical Engineering at Clemson University in Clemson, S.C., and his brother, Michael Zumbrunnen, a mechanical engineer with

a background in product and software development and commercialization. (See Learn More box.)

HOW IT WORKS

The melt streams to be combined are each fed by their respective extruders into the “smart blender,” a barrel or cylinder containing two or more independently rotating stir rods that cause the chaotic advection motion and create a defined melt structure rather than a homogeneous blend. The smooth stir rods rotate at different speeds in specific periodic sequences. The rods’ rotation stretches and folds two or more melt streams into a “marble cake” pattern, but on a micro scale. The rods are oriented lengthwise in the barrel and taper at the downstream end to leave space so the structured melt can flow out without disturbing the pattern.

The rotating rods create micro- or nano-layers. A specific rod rotation sequence can create morphologies with hundreds or even thousands of layers. A variety of melt structures can also be derived from the layers, formed by repeated stretching and folding, which break up the layers to form derivative shapes like ribbons, long fibers, and thin platelets, as well as the more conventional morphology of droplets of one material dispersed in the other.

A sponge-like interpenetrating material can result from simultaneous ruptures in a multi-layer melt. Prof. Zumbrunnen notes that spongy material blends can also be made in a twin-screw extruder, but without as much variety or control over end properties. “Believe it or not, we can also cause the rods to rotate so that an outer layer is coextruded while the inner core is blended,” he adds. These varied morphologies can be retained after extrusion through a round or flat die.

Smart Blending’s first two commercial machines each use a different blending-chamber shape and rod configuration, depending on whether the end product is tubular or flat film. The first machine was for cast film, delivered in December 2007 to a maker of packaging film in the Midwest. It consists of two independently driven rods in an oval barrel that is placed between two or more extruders and a modified conventional flat die. The die was built by Premier Dies Corp., Chippewa Falls, Wis., with a wider than normal infeed and a longer, more streamlined body to preserve the blend morphology created by the stir rods.

NOW IN BLOWN FILM

The latest and most complex device so far is the first Smart Blender for blown film, which was delivered late last year to another film producer for product development. In this case, the blending device is installed vertically and replaces a blown film die, so the structured blend is extruded directly through an air ring and blown into a bubble.

The device consists of a section to distribute polymer melts from two (or more) extruders into an annular blending chamber. The chamber has six rods mounted between two concentric cylinders. Each rod is independently driven by a variable-speed motor. The rods are rotated in a periodic sequence, determined by computer simulation.

From the chaotic advection chamber, the structured blend enters a streamlined flow path leading to the exit lip, where melt is formed into the bubble. This first device has a 4-in. opening with a 4:1 BUR to produce a 16-in. diameter bubble.

Potential resin combinations include pairs of immiscible polymers or polymers with different surface tension, typically in 80/20 or 85/15 blend ratios. Combinations can include LDPE/EVOH, PP/EPDM, PS/PP, nylon 6/EVOH, or LDPE/PS. Smart blending can also combine similar polymers like HDPE and LDPE into a film 500 microns thick with over 20,000 nanolayers, each less than 12 nm thick.

More than two materials can be combined—for example, into a blown film containing sub-micron-thick alternating layers of nylon 6, nylon 6 plus nanoclay, and EVOH. Such a film exhibits barrier properties never before achieved, Prof. Zumbrunnen says, because of platelet alignment and localization of platelets within the numerous layers.

The Smart Blending device is supplied with a license from Clemson University. Three other chaotic advection devices were built under earlier licenses, based on Zum-brunnen’s original lab machine at Clemson, which was a cylinder with two stir rods. One licensee in Korea is believed to have developed its own device.

All the industrial machines built so far are believed to be under 500 lb/hr capacity. “If someone wanted a system for 2000 lb/hr, we could build it, but it would take more time,” Prof. Zumbrunnen says.

Smart Blending will deliver three technical papers on recent trials with the production-scale devices at the SPE ANTEC conference in Chicago in June, during the NPE show. One paper discusses the smart blender for blown film and its capability to make micro and nano layers or various polymer blend morphologies. A second presents realistic wood graining in films with chaotic advection of pigments in the melt. And a third is on polymer morphologies for timed release of additives from films, such as antioxidants in food packaging. Smart Blending Technologies will also exhibit in the Emerging Technologies Pavilion for Nanocomposites at NPE.

Related Content

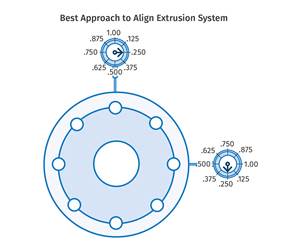

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreRead Next

'Chaotic Advection' Creates New Polymer Blend Morphologies

A continuous blending device called the SmartBlender is creating polymer blends with novel properties by folding the two melts together, rather than distributing one evenly throughout the other.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)