On-Site: Well, Well, Well... Processor Taps into Novel Underground Cooling Solution

In 2008, Olle Mannertorp and his co-owners of Multifilm Packaging (multifilm.com) had a decision to make.

In 2008, Olle Mannertorp and his co-owners of Multifilm Packaging (multifilm.com) had a decision to make. They had just recently purchased the film extruder and converter, based in a 78,000-ft² plant in Elgin, Ill., as part of a management buyout from its former Austrian parent; and they were immediately confronted with 300+ tons of chilling capacity that needed to be replaced. Two years and $1.2 million later, Multifilm had gutted its former temperature-control system and installed what is believed to be a first-of-its-kind solution in plastics processing—a geothermal process-cooling & HVAC System that cools not only the equipment, but keeps things comfy for the people who work there.

The decision has had significant bottom-line implications for the $20-million company, which processes PP- and PE-based films on two cast lines, and then prints, metalizes, and laminates them, primarily for food and candy packaging, including twist-wrap films for classic Starlight Mints. “We certainly looked at the latest in chilling technology when we realized we had to get rid of our old system,” said Mannertorp, Multifilm’s CEO. “We saw that there had been significant improvements in energy efficiency in conventional chilling technology. But at the same time, we wanted to try something different and to make a substantial impact on the energy we consume and on our carbon footprint.”

Multifilm conducted an internal analysis comparing energy comsumption from July-Oct. 2009, when it still was using its previous cooling system, with the same period this year. It discovered that the geothermal system had cut its overall energy expenses by roughly 15%—and close to 80-90% on the chiller process alone—even though this past summer was quite a bit warmer in the Chicago area. On top of that, Multifilm had produced 33% more film during the 2010 period.

The film producer has an open-door policy for other plastics processors who would like to see first-hand what geothermal cooling can accomplish. As of mid-November, two injection molders and one sheet extruder/thermoformer had scheduled visits. “Sharing technology is a way that we can raise the level of manufacturing in the U.S. for everyone’s betterment,” is how Mannertorp puts it. “We are not secretive about the project and encourage other manufacturers to learn from us and also reduce their carbon footprint. In the long run, everybody benefits.”

THE DRAWING BOARD

The process started in late 2008, when Mannertorp called Clive Maidment, a European consultant with extensive experience in water and energy management, to pick his brain on the most-efficient cooling options currently available. “The first thing Maidment told me was, ‘Your plant is probably sitting on top of a huge lake of cold water, so why don’t you dig a hole and start there.’”

Still not entirely sold on the idea, Multifilm brought Maidment on board. The consultant worked with Mannertorp and one if his partners, COO David Rohrschneider, to outline the company’s needs and draft a rough outline of the components needed for a geothermal cooling system. The design stage took several months, and with each iteration, the team saw more potential in the system than they initially thought. “At first, we were thinking about just replacing the chiller to cool our equipment,” says Rohrschneider. “But the more we thought about it, the more it made sense to cool and heat our plant as well.”

The latter part is the unique aspect of the company’s system. At first glance, its array of pipes, fittings, and valves looks quite complex. In reality, it’s compact—occupying a space in the plant about 40 ft long × 9 ft high—and fairly straightforward: Water is pumped out of the ground at a constant 52 F to cool the plant during the summer and the machinery year-round. In the winter, the heat generated by the machinery is diverted to warm the plant. “We pay for all this energy anyway, so why waste it,” says Mannertorp. It’s a closed-loop system: The water is pumped back into the ground, completely untouched.

But first Multifilm had to find out if it was allowed to “explore” underground, and just how deep it would be permitted to drill. By May 2009, it had navigated through the bureaucratic maze and drilled an exploration well to look for water. “With our close proximity to the Great Lakes, we knew there was water on the property, we just didn’t know at what depth,” explains Maidment. “We drilled a 365-ft test well, and hit the aquifer at about 280 ft.” Several tests confirmed that Multifilm had a flow of about 400 gal/min, more than enough to proceed with the system.

More wells were drilled over the next few months, and when all was said and done, Multifilm wound up with three “production” wells for water supply, and four return or “rejection” wells to pump the water back into the ground. The wells are on the opposite ends of Multifilm’s property so as not to interfere with each other and to create a balanced loop. Water quality is critical when dealing with groundwater, so the Multifilm system filters it for sediment and sulfur and iron bacteria.

The design phase of the system took several months of translating needs and ideas into a workable blueprint. After that, a Chicago-area company was hired to install heat exchangers, pump motors, filters, valves, and air handlers, connected by thousands of feet of copper piping throughout the plant. This process lasted close to four months, and was probably the most challenging part of the installation, given Multifilm’s finite amount of space.

The piping loops were completed in April 2010, and tested and tweaked extensively to make sure that the water flow and temperatures were adequate. One by one, the processing machines were disconnected from the old chiller and connected to the geothermal system, starting with the cast-film lines and finishing with the printing presses in mid-June. The system ran in manual mode at first, but a month later, the control logic had been optimized enough for the process to run automatically.

Mannertorp candidly admits that Multifilm “blew the budget several times” on the installation cost of the geothermal system. Adds Rohrschneider, “But those costs must be looked at in association with reduced maintenance, significantly lower energy costs, and all the benefits brought about by changing a system throughout the plant that had reached its end of life.”

About 25% of the upfront cost of the system will be refunded to Multifilm in form of grants from the U.S. Government and the local utility, ComEd. In addition, Multifilm expects significantly lower maintenance costs compared with conventional cooling technology, since the pumps, valves, and heat exchangers can be easily replaced. “All in all, we are looking at a 5-year return on investment,” says Mannertorp.

Related Content

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

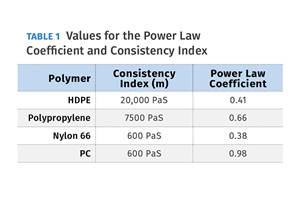

Read MoreThe Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More