Processing Biopolymers for Rigid Sheet & Thermoforming

Tips and Techniques: PHA extrusion/thermoforming

Newly available cast sheet and thermoforming grades of Mirel biobased polymers open up a new range of applications in containers and other formed parts where renewable content and biodegradability are desired.

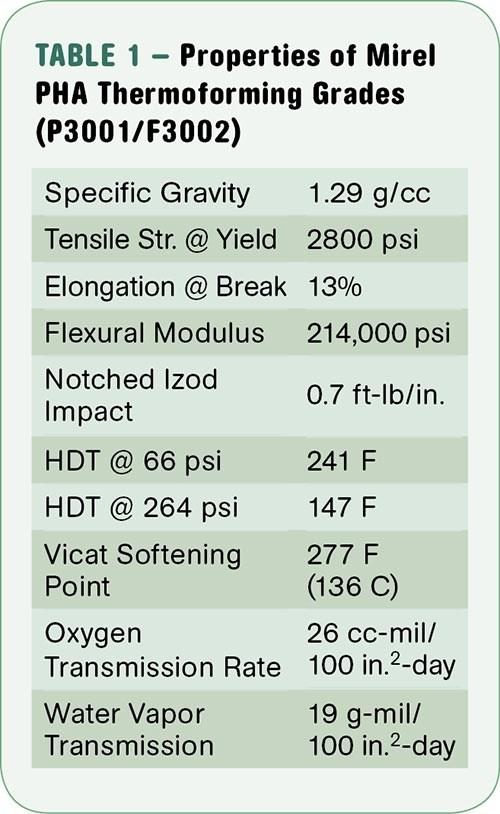

Newly available cast sheet and thermoforming grades of Mirel biobased polymers open up a new range of applications in containers and other formed parts where renewable content and biodegradability are desired. These bioplastics are FDA food compliant and offer a property balance similar to HIPS (see Table 1) and processing similar to HIPS or PP. Mirel comes from Telles of Lowell, Mass. (mirelplastics.com), a joint venture of Metabolix, Inc., and Archer Daniels Midland Co.

Mirel bioplastics are semi-crystalline thermoplastic polyesters derived from microbial fermentation of plant sugars, principally from corn, though the process can be engineered to use other renewable feedstocks, such as palm oil. Mirel is a type of PHA (polyhydroxyalkanoate), specifically a proprietary blend of PHB (polyhydroxybutyrate) copolymers, additives, and mineral fillers. It is produced at a 110-million-lb/yr plant in Clinton, Iowa, which opened in 2009.

Mirel PHA is BPI-certified to meet U.S. standards for compostable plastics according to ASTM D6400. It also meets the ASTM D7081 standard for non-floating biodegradable plastics in a marine environment. Mirel has been Vinçotte-certified in Europe for biodegradability in natural freshwater environments, natural soil environments, industrial composting, and home composting.

Telles’ Mirel 4000 series is for sheet applications, while its Mirel 3000 series is designed for thermoforming. Both have been commercially available since October 2010. Telles offers each series in a “P” version for general-purpose applications and an “F” version for food contact.

The Mirel 3000 series (P3001, F3002) are high-melt-strength grades designed for low heat sag in thermoforming. They are suitable for a wide range of medium-draw foodservice and packaging applications, including hot and cold cups, cup lids, yogurt containers, tubs, trays, and single-serve food packaging. Applesauce containers, temporary foodservice trays, coffee cups and lids, pipette trays, and pill boxes are already being considered.

Mirel sheet has been used in the new bottomless plantable pot manufactured for Ball Horticultural Company, West Chicago, Ill., and available at Lowe’s home-improvement centers. Made of rolled sheet with a welded seam, Ball’s SoilWrap plantable pot replaces PS or PP containers that hold a new plant in place when they are planted into the earth. The PHA pot biodegrades in the soil.

Mirel grades for injection molding are already commercial. (An injection molding guide appeared in Plastics Technology’s August 2010 issue.) One notable application is the line of Paper Mate Biodegradable pens and mechanical pencils, introduced last year. Another is the disposable tray for a laboratory pipette reloading system from Labcon North America.

Telles also produces a special blended blown film grade, tradenamed Mvera, for industrial compostable can liners, retail bags, yard-waste bags, and stretch wrap. The company is developing additional Mirel grades for film extrusion, extrusion coating, foam, non-woven fibers, monofilament, and blends and alloys.

SHEET EXTRUSION GUIDELINES

Mirel 4000 series cast sheet grades feel like PVC card stock, can stand up to multiple uses, can be converted on standard equipment, and offer processing characteristics similar to extruded HIPS, says Allen Padwa, senior fellow at Telles. Mirel sheet runs at similar extrusion rates, he notes, and delivers good surface finish, and printability.

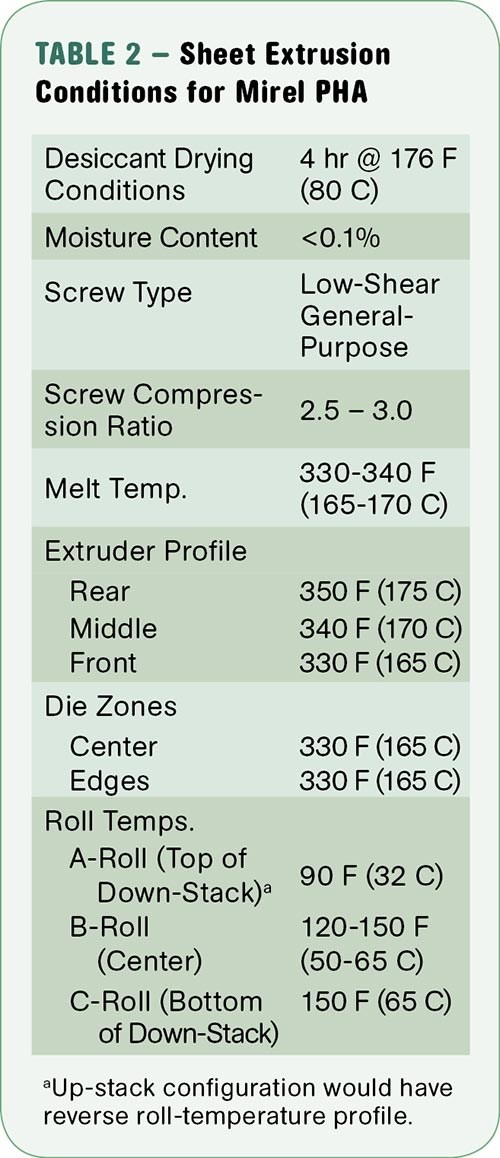

The cast sheet grades are high-molecular-weight polymers with a melt index of about 1.0. Drying requirements for these biodegradable materials are not as stringent as for PLA biopolymer, which can require moisture content below 500 ppm. Mirel extrusion grades can be processed with a moisture level of 800 to 1000 ppm, or about 0.1%, says Daniel Gilliland, director of business development. Mirel is shipped dry and ready for processing, but if the material is exposed to moisture, Telles recommends drying in a desiccant-type dryer with a dewpoint of -40 F for 2 to 4 hr at around 176 F.

Mirel can be extruded on conventional equipment designed to run polystyrene. The material requires a low-shear, general-purpose screw that has a compression ratio between 2.5:1 and 3.0:1, which will minimize heat build-up in the material. L/D ratio should be kept short to prevent overheating or over-shearing. Mixing elements can be incorporated onto the screw, but be sure they are low–shear, advises Gilliland. Padwa says that because Mirel PHA contains low residuals, either vented or non-vented extruders can be used.

Perhaps the most important fact about extruding Mirel is that melt temperatures are significantly lower than for conventional polymers such as PVC or PS (see Table 2, p. 33). It is thus important that the extruder as well as feeders, blenders, and other pellet handling equipment be thoroughly purged of other resins before running Mirel. Temperatures above 392 F or excessive hold times can give rise to PHA polymer degradation.

As shown in Table 2, Telles recommends a reverse extruder temperature profile (hottest under the hopper, coolest at the die), to minimize thermal degradation and to generate a homogeneous melt. “Mirel should be processed near its melting point, at or below 340 F,” says Gilliland. Unlike petroleum-based materials, which are typically heated significantly above their melting point, prolonged heating of Mirel above its melting point could adversely affect material properties. “As Mirel degrades its viscosity decreases but its color remains unchanged,” notes Padwa.

Standard screen packs of 40-100 mesh should be used to homogenize the melt. Finer screen packs can result in excessive heat buildup and molecular-weight reduction.

A conventional coat-hanger die can be used to extrude Mirel sheet. If unmelted resin is seen emerging from the die, processors should raise the rear and mid-barrel temperatures while keeping the front barrel and die temperatures unchanged. Lowering the die temperature is not recommended, as recrystallization can occur in stagnant zones, which can create solids in the melt. The solids can slough off surfaces that are below 330 F. Telles suggests a die gap 0.02 to 0.05 mm greater than the desired sheet thickness.

The roll stack can be configured in a top-roll or down-stack position for the A-roll. Suggested roll temperatures are shown in Table 2. When using an up-stack setup, the temperature profile would be reversed. The A-roll should have a low-surface-energy coating. The B-roll can have a high-gloss chrome or matte finish. Any finish is allowable for the C-roll.

Mirel sheet reportedly runs at rates, pressures, and yields similar to those for PS. It has been extruded at 600 lb/hr on a 3.5-in. single-screw extruder having a screw with a 2.5:1 compression ratio. Linear extrusion rate for 0.7-mm (28-mil) sheet was 12 ft/min.

If the process is interrupted for more than 1 hr, PHA polymers become susceptible to thermal degradation. Telles suggests that the screw be kept turning at a low rate (5 rpm) or purging with LDPE without changing the temperature setpoints. If the extruder is stopped with Mirel in the barrel, crystallization can occur in the cooler zones, such as the die. Telles suggests heating those sections to 350 F to melt the polymer, then lowering the temperature back to process setting when extrusion is restarted. At the end of the run, all zones should be heated to 350 F and purged with LDPE.

THERMOFORMS LIKE PP

Mirel PHA looks and feels like polypropylene or polystyrene. It processes similar to PP in cycle time and mold release, and its property balance is similar to HIPS (Table 1). Thermoforming grades have a heat-distortion temperature above 212 F, which allows for microwaveable food containers and autoclaveable medical/pharmaceutical trays and boxes.

Mirel 3001 series can be thermoformed on conventional equipment using commonly used techniques. Telles cautions that it is important not to overheat the material. If it sags and contacts the heaters it will degrade to low-molecular-weight organic acids, which are noxious. The softening temperature best for thermoforming is 311 to 388 F.

Telles says the materials form best at a slow draw rate. The plug penetration rate should be slowed so that melt rupture does not occur. Pressure and/or vacuum delay times should be increased, if possible, so that the plug assist is completed prior to pressure/vacuum forming. Pressure and vacuum build rates should be minimized to prevent melt rupture. Processors may use a little more pressure than vacuum, says Padwa. For example, vacuum might be on for 0.5 sec vs. 2 sec.

Mirel bioplastics crystallize most rapidly at 140 to 158 F. So, for a single-station thermoforming unit, Telles recommends setting the mold temperature about 140 F and allowing for a longer cooling time. Once good parts are produced, Telles suggests decreasing the mold temperature in 20° F increments to optimize cycle time.

In continuous, in-line thermoforming, even cooler molds can be used. Mirel says it is important for the sheet temperature to be around 140 F, but since the residence time in a continuous forming operation is generally shorter, a lower mold temperature is required to cool parts faster. Using an infrared thermometer to assess part temperature as it exits the mold can provide guidance.

Related Content

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreDie-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

Read MoreGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreDavis-Standard to be Systems Integrator for Novel EDI Flat Die

Die uses motorized lip-adjustment, said to be three to five times faster than heated-bolt adjustments.

Read MoreRead Next

Injection Molding PHA Bioplastics: Validating Moldability for Paper Mate Pens

As part of the commercialization process for Mirel PHA bioplastics, it became necessary to validate the injection molding process for a high-profile consumer products launch.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)