Die-Service Cart Upgraded to Handle Screws, Chill Rolls

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus.

Processing Technologies International LLC has released its next-generation flat die servicing system, the uCAMS (Universal Cleaning Assembly and Maintenance System) Plus. The original uCAMS, introduced in 2021, was developed to be the foundation of any offline die maintenance program, serving as a single manifold flat die servicing system capable of accommodating a variety of die widths.

The latest iteration evolving from the original concept (patent pending) has brought even greater effectiveness to servicing flat dies with the upgrade for maintenance of chrome rolls and feed screws. This transforms the functionality of the flat die service system into a multi-purpose “triple-play” for sheet extrusion related critical component maintenance and service, unmatched throughout the industry.

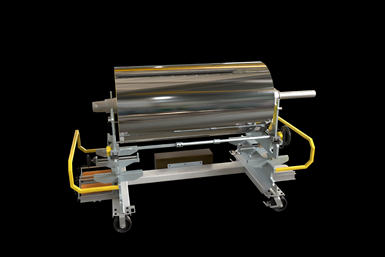

Like its predecessor, the new unit offers mobility, ease of use by a single operator and safe accessibility. All previous features included in the original uCAMS have evolved into the newest generation including a hand wheel mechanism for splitting flat dies and trunnion supports coupled with rollers that permit rotating die halves 180° with ease.

Photos: PTi

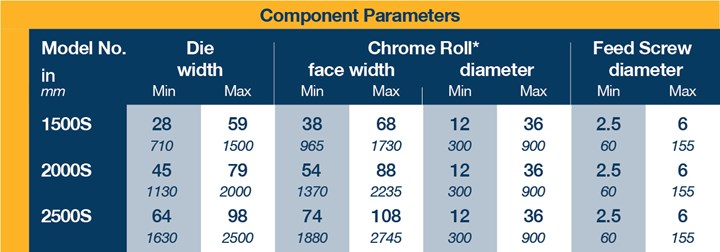

Available in three models —1500S, 2000S and 2500S — uCAMS Plus accommodates servicing flat dies ranging from 710 to 2500-mm widths via its unique adjustable trunnion supports, eliminating the need for multiple, width-specific carts and/or trunnions.

This unique design feature allows uCAMS Plus users to maximize application flexibilities by permitting effortless width adjustments to take place via the turn of an adjustment wheel, thereby allowing for precise placement and alignment of the die in the trunnion upright cradles that are integral to the unit.

Furthermore, digital width position indicators coupled with special threaded mechanisms prevent unwanted position changes from occurring and accommodates a variety of die widths to be serviced with quick and easy set-ups.

Sold as an add-on upgrade to the base system, uCAMS Plus transforms into a servicing station for chrome rolls and feed screws, increasing the purpose of the system threefold. With the addition of special uCAMS Plus components, the system is converted for the purpose of servicing chrome rolls and feed screws.

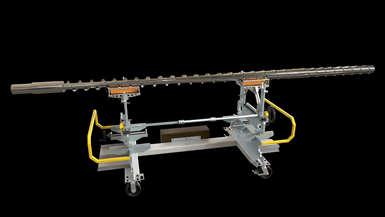

uCAMS Plus upgrade is comprised of two pairs of A-frame and feed screw roller support assemblies, each of which features stowage cradles that keep the components organized when not being used.

By mounting the A-frame supports via means of toolless quick-pins to the upright die trunnion support cradles of the uCAMS frame, the unit is now able to service chrome rolls. Additionally, the A-frame supports feature recessed bronze rollers used to protect the chrome roll journals from damage when rotating in the supports during service activities.

Similarly, by mounting the feed screw roller assemblies onto the A-frame supports via toolless quick-pins, the unit is easily converted into a feed screw service station. The maximum weight limits for uCAMS service components are 6000 lb for flat dies and chrome rolls and 2000 lb for feed screws (see chart below).

Related Content

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

-

Non-Contact Control of Flat Dies, Adapters

More automation comes to flat die technology.