Stop Shopping for a 'Jack of All Trades' Extruder

Some processors try to find “fits all” extruders to cover all processing possibilities. But you’d have to grossly overpower it to achieve this, and that’s expensive up front and will result in inefficiencies over time.

Selecting the right extrusion equipment for the job is important for ease of operation and profitability. Yet there remains an industry tendency to try to get a “fits all” extruder to cover every current and future contingency.

For example, I recently consulted for a processor that bought a used extruder with a 38:1 L/D and a vented barrel. The machine had originally been used for processing HIPS. The new owner was running a low melt flow HDPE recyclate and had replaced the vented barrel with a non-vented barrel. The extruder did not have enough torque capacity to reach the previous HIPS output with HDPE. I found it was impossible to design a screw that could meet the planned output without operating at excessive melt temperatures.

Converting to a non-vented barrel resulted in an additional 5-8 turns of the screw in the shallower channels in the vent area, thereby further increasing the overall shear stress and melt temperature. The exact choice of extruder features is a pretty complicated task, unless you are very knowledgeable in extruder design and polymer properties. In this case, it was assumed the longer L/D would be advantageous in processing of recycled HDPE because of the improved mixing.

Polymers that take more energy to reach melt conditions — such as low melt flow HDPE — require more drive torque. So, you need to know your desired output and calculate the required amount of horsepower and screw speed. It’s also necessary to have that horsepower at the precise screw speed in order to develop that output from the screw. So, horsepower, maximum screw speed and estimated output per screw revolution are required.

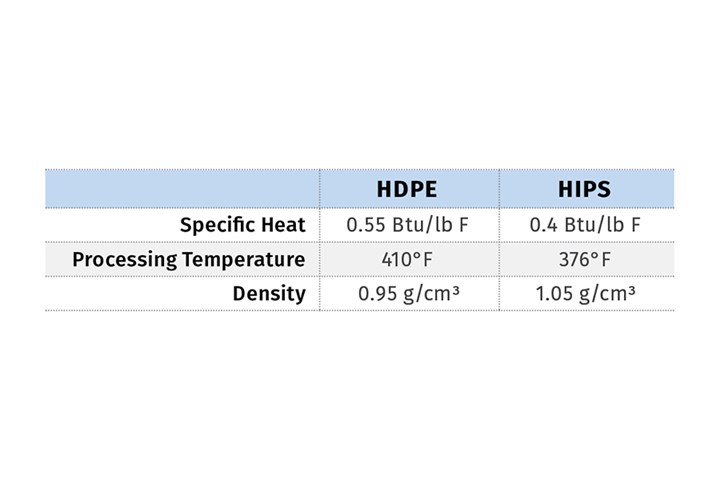

Always keep in mind that many polymers are processed preheated which greatly reduces their power requirement. As a sample, I compared the energy requirement per pound for HDPE and HIPS to reach its normal processing temperature with no preheating:

Combining these physical properties shows that it takes approximately 1.66 times more energy to raise the temperature of HDPE to its average processing temperature than HIPS. Heat of fusion for HDPE and differences in thermal conductivity are being ignored here for simplicity, but they make the ratio even worse.

Polymers that take more energy to reach melt conditions require more drive torque.

Based on this analysis, the extruder should be capable of processing more than 1,800 lb/hr of HDPE versus the previous 3,000 lb/hr of HIPS (3000 ÷ 1.66=1807 lb/hr). However, because of the long L/D the output had to be further reduced to control the melt temperature. That was because of it being redundantly overheated in the long L/D it actually had to be reduced to reach the desired melt temperature and it produced only a little over 1,250 lb/hr of usable output.

Analyze Polymers, Desired Output

Based on this example it’s obvious that one of the most important considerations in choosing an extruder is to analyze the specific polymers and desired outputs to be processed compared to the drive power. There are a number of other important considerations, but this is likely the most critical.

Determining the best L/D requires some very specialized screw design calculations and polymer knowledge. A venting requirement adds 4-7 additional L/D, except in special cases. Without venting, a 30:1 L/D is usually appropriate for most applications, so any longer barrels usually have some special processing requirements.

The point is that an extruder is a more specific piece of equipment than most processors believe and has a definite range of application unless you are prepared to grossly overpower it to cover all possibilities. Not only is this initially expensive at the purchase but the efficiency declines as the speed and load decreases due to increasing percentage of mechanical loss, thereby making for a long-term economic loss.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting LLC. Contact jim.frankland@comcast.net or 724-651-9196.

Related Content

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreShredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

Read MoreTroubleshooting Flow Surging in Single-Screw Extruders

Surging can cause lower production rates, higher scrap rates, material degradation and higher labor costs. Here is a guide to troubleshooting this problem.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)