Teel Straps on Yellow Belt to Cut Scrap on Big Cores

Investments in a lean, continuous process pay off for this Wisconsin processor.

Teel Plastics quickly took advantage of a recent Yellow Belt Six Sigma course held at its plant in Baraboo, Wis., to improve the efficiency of one of its large-diameter film-core extrusion lines. A project stemming from the course involved implementation of lean principles to improve the scrap rate of the line.

A team of Teel engineers, led by Jon Ahlstrom, development technician; and Michael Birch, manufacturing specialist, used the lean process DMAIC (define, measure, analyze, improve, and control) to evaluate this line’s scrap production and implement improvements. Teel’s goal was to reduce scrap production by 29.5%, with the improved yield both increasing the capacity of the line and reducing its environmental impact.

For most of 2021, the scrap rate averaged higher than target, Ahlstrom notes. The large parts extruded on the require large quantities of material, slower running speeds, and tight tolerances, all factors that make it harder to control scrap. Previous projects aimed at improving the rate on the line were successful at first but did not prove sustainable. The team taking the Yellow Belt class sought to apply the principles they had been learning and see whether they could finally tackle it.

Teel extrudes large-diameter cores for the automotive film industry, and set out to slash scrap generated from one of its lines by close to 30%. (Photos: Teel Plastics)

“At the start, the team conducted a study, collecting the scrap created on different areas of the line during a typical extrusion run and determining the causes,” says Birch. “From examining one work order specifically, we identified TIR (total indicator runout) adjustments and startup work (including sizing and setup tooling) to be the primary factors contributing to excessive scrap.”

TIR is a term used in manufacturing cylindrical parts that refers to the difference between the maximum and minimum measurements along the surface of a part. The measure shows how much the part deviates from a number of dimensional attributes, such as roundness, concentricity and straightness, and is a measure of how far the part deviates from a perfect cylinder.

The size of the parts and slower line speeds mean adjustments to TIR during production are slow to take effect. The tight tolerances create difficulty in getting them just right, in turn increasing scrap. Moreover, problems associated with the placement of initial tooling and incorrect sizing adjustments on startup also impacted scrap rate.

One of the primary setup issues identified was difficulty in proper cooling setup, involving the placement of spray rings in the appropriate locations. Spray rings are large metal rings located in the front of the cooling tank. They spray the hot parts with water as they run though the rings, serving as an initial means of cooling and solidifying the product. Different parts require different ring locations, and incorrect placement can contribute to scrap.

Implementing Improvements

After analysis, the team focused on several main approaches to improvement. First, they determined that increasing the standardization and precision of equipment placement at startup would help. One setup improvement was to use laser alignment during cooling-tank installation. Another was to add information to the setup sheets used by technicians, including equipment position notes and flow parameters. Finally, a key standardization improvement was the development of metal quick-change plates onto which the spray rings could be affixed using pre-drilled holes.

Explains Birch, “Instead of requiring technicians to place each individual ring in the correct location, they are now added to plates that place the rings in the precise locations required for a given part. The quick-change plates increase accuracy by eliminating setup error, and they reduce labor time because they can be quickly removed as a unit and added as needed.”

Spray rings on a newly developed quick-change plate allow operators to more-precisely direct cooling water where the part needs it.

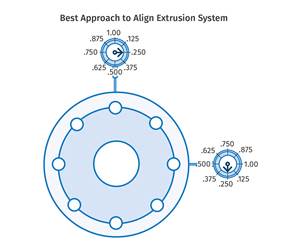

To address the TIR adjustment issue, the team decided to provide more helpful resources to operators during a run to help them adjust accurately and efficiently. This involved creating a TIR adjustment guide to be included on the line. Operators also received training on how to use the guide.

Teel reported promising results after two runs of product with solutions implemented—scrap rates were slashed beyond the 29.5% goal. Moving forward, says Birch, focused training will be provided to operators to ensure they continue to take advantage of the improvements. Because of the success of the changes made, the team suggested making similar improvements to other extrusion lines at Teel, Birch adds.

“This project exemplifies the value of investing in a lean, continuous-improvement mindset,” states Ahlstrom. “The project increased efficiency in manufacturing the core line parts, reduced waste, and helped make an operator’s job faster and more straightforward.”

Related Content

Specialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

Teel Gets Government Contract for Swab Sticks

Grant will allow Teel to produce hundreds of millions more swab sticks for Covid-19 test kits.

Read MoreMaterials Knowledge Pays Off at Teel Plastics

Well-equipped and well-staffed testing lab elevates competence of custom processor.

Read MoreIoT Strategy Cuts Human Error at Teel

Controlling up to 20 parameters from a single web interface has slashed setup time and increased output at a leading profile processor.

Read More

.png;maxWidth=300;quality=90)