Your Business In Brief - January 2000

Yushin Opens Midwest Robot Technical CenterInjection molding robot supplier Yushin America, Inc., Cranston, R.I., has opened a technical center in Indianapolis.

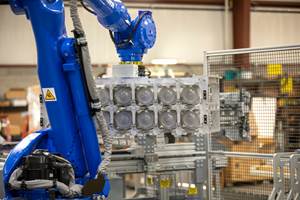

Yushin Opens Midwest Robot Technical Center

Injection molding robot supplier Yushin America, Inc., Cranston, R.I., has opened a technical center in Indianapolis. It will provide application engineering and integration services, installation, repair, maintenance, and training. It includes a showroom with robots and end-of-arm tooling.

Exxon & Mobil Complete Merger

After an 11-month investigation, the U.S. Federal Trade Commission (FTC) last month approved the merger of Exxon Corp. and Mobil Corp. to form Exxon Mobil Corp., the largest publicly traded oil and petrochemical company in the world. The merger was then consummated immediately. The FTC required no divestiture of plastics-related interests.

The new ExxonMobil Chemical Co. is headquartered in Houston. It has four global business groupings—Basic Chemicals, Polymers, Intermediates, and Films (the last based in Macedon, N.Y.).

Bayer to Buy Lyondell’s Global Polyols Business

Bayer AG in Germany will purchase Houston-based Lyondell Chemical Co.’s worldwide polyols business. The purchase does not include Lyondell’s global TDI business.

Ciba Finds a Buyer For Its Epoxies

Ciba Specialty Chemicals, Basel, Switzerland, will sell its Performance Polymers Div. to the investment firm Morgan Grenfell Private Equity (MGPE) in the U.K. MGPE is the private equity arm of Deutsche Asset Management in Germany.

Ciba Specialty Chemicals is one of the world's top three epoxy resin producers. It also supplies tooling materials, adhesives, and photopolymers.

Headquarters of Performance Polymers will remain in Basel. U.S. operations are located in Brewster, N.Y., and East Lansing, Mich.

Cumberland Teams with ReTech

Cumberland Engineering LLC, South Attleboro, Mass., and ReTech Industries Inc., High Point, N.C., have formed a strategic business alliance that makes ReTech the exclusive supplier of single-shaft rotary grinders to Cumberland. The ReTech single-shaft rotary grinder precuts large, dense, and bulky waste by hydraulically feeding it into a low-speed cutting rotor. It can be paired with a Cumberland granulator to form an efficient two-stage size-reduction system.

Battenfeld Cancels Sale of Injection Business

SMS AG in Germany announced that it has terminated the impending sale of its Battenfeld Injection Molding Technology unit to Madison Capital Partners of Chicago. Although a definitive contract had been signed on October 1, the sale could not be executed because Madison was not able to provide appropriate financing, SMS said. According to a Battenfeld source, there are no prospects that the deal could be revived.

For Bottles with a Special Look, A Color House Blows Its Own

Some special coloring effects for plastic bottles cannot be evaluated with a standard color chip, but only an actual bottle. It is especially true of effects that are best achieved with a multi-layer structure. That’s why Clariant Masterbatches Div., McHenry, Ill., recently installed its own coextrusion blow molding machine. The model BW 1000 EC, a single-station shuttle machine from Uniloy Milacron, Manchester, Mich., helped Clariant develop what is said to be the first multi-layer PE bottle with an anodized-aluminum look that is molded in rather than applied by vacuum plating and lacquering.

With this machine, prototype development that used to take from eight to 24 weeks can be achieved in two days. "We had to mix many combinations of material, ship them to a quality molder, and then tie up a production machine," says Len Kulka, personal-care packaging product manager.

He explains how the multi-layer structure helps reduce pigment cost and improve special effects. “In a mono-layer structure you create sort of a ‘mud mix’ when different colors are blended because you lose reflectivity.” Coextrusion improves special effects by putting one color in the outside layer and a different one in the middle layer. This gives Clariant flexibility to change characteristics such as color, clarity, reflectivity, and texture.

For example, Clariant can change the levels of reflection and refraction in the thin outer virgin-resin layer. The level of translucency can be changed in the middle layer, composed of trim scrap and post-consumer waste. The machine’s stability and repeatability helps Clariant reduce expensive overuse of additives such as uv absorbers. Kulka also notes that good parison and concentricity control allows making small variations in layer structure. The head design permits color and layer changes in just 30 min.

Wentworth Gets Second U.S. Mold Shop

The world’s largest manufacturer of molds for PET and extrusion blow molding has acquired a second U.S. manufacturing facility. Wentworth Mold Inc., Hamilton, Ont., recently purchased the Kansas City, Mo., mold shop of Owens-Brockway Plastic Products Inc. The shop was renamed Wentworth Mold Inc. Central USA Div. The firm’s other U.S. plant, Amtech East Inc. in Pawcatuck, Conn., is now called Wentworth Mold Inc. East USA Div.

Conair & Fanuc Robotics Form Automation Alliance

Conair in Pittsburgh and Fanuc Robotics North America, Rochester Hills, Mich., have agreed to join forces on automation projects. This “integrator agreement” expands Conair’s automation capabilities beyond parts-removal robots to include post-mold functions such as degating, trimming, palletizing, bonding, and assembly. Fanuc offers articulated-arm, AC servo-driven robots. The smallest is a six-axis tabletop unit. The largest takes payloads up to 441 lb and has up to 122-in. reach.

Uniloy Takes First Step Into Two-Step Machines

Blow molding machine supplier Uniloy Milacron, Manchester, Mich., is developing its first PET reheat stretch-blow molding (or two-step) machine, says David Yenor, director of market development. Uniloy Milacron hopes to roll out the new model at the NPE 2000 show in Chicago this June. Uniloy Milacron currently builds integrated (or single-step) injection stretch-blow machines and reheat blow molds.

The new machine is being developed initially for the dairy and beverage market, but will also serve applications such as wide-mouth jars, hot-fill containers, and multi-layer beer bottles. Yenor says output per cavity is projected to be competitive with the fastest machines on the market.

Hasco & Mold-Masters Form Hot-Runner Alliance

Hot-runner supplier Mold-Masters Ltd., Georgetown, Ont., has formed a strategic alliance with mold-components maker Hasco-Normalien in Germany (represented here by Hasco-Internorm Corp. West, Chatsworth, Calif.). The firms will jointly market in Europe and North America a series of new hot-runner products developed by Mold-Masters. The first product of this alliance is Mold-Masters’ new Temp-Master multi-zone temperature controller (see p. 11). Future releases will include hot-runner components designed by Mold-Masters for Hasco.

Kafus Starts Up Plant For Natural-Fiber Composites

The new Elkhart, Ind., plant of Boston-based Kafus Bio-Composites, Inc., became fully operational last month. The company is now shipping Flexform natural-fiber composite mats to automotive trim manufacturers for use in 2000-model vehicles. One user is Findlay Industries, Findlay, Ohio, which produces Saturn deck trays, Ford Cougar door panels, and truck interiors for International, Volvo, and Mack Truck.

The formable mats, made of polypropylene and kenaf fiber, are also used by Visteon Automotive Systems, Dearborn, Mich., for parts in the 2000 Lincoln Continental and Ford Mustang, Escort, Taurus, Focus, and Mercury Sable. Kafus expects to ramp up to 24-hr production by July and to commission a second manufacturing line by year’s end.

Struktol Buys Morton’s Antioxidants Business

Polymer additive producer Struktol Co. of America in Stow, Ohio, has agreed to purchase the thioester antioxidant business unit of Morton International, Inc., North Andover, Mass. The acquisition will include Morton’s Carstab DSTDP and DLTDP, as well as its Morstille 18 DSTDP pastilles.

A Third of Car Manifolds Will Be Plastic by 2004

Injection molded plastic intake manifolds now have 24% of the automotive market in North America, but that share will grow to 33% by 2004, according to Automotive Fuel Systems—1999, a new global multi-client report from TownsendTarnell Inc., Mount Olive, N.J. In the global auto industry, nylon intake manifolds now account for 20.8% of the market. That is expected to increase to 45.4% in 2004. The report also says all of today’s North American plastic intake manifolds are of nylon 66, but one-third of them (11% of the total) will be nylon 6 in five years.

Related Content

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)