3D Printing Helps Niche Manufacturer Bring Product to Market

PT sister publication Additive Manufacturing showcases an interesting example of a unique product manufactured via 3D printing.

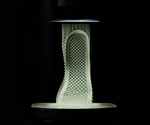

One of the many exciting benefits of additive manufacturing is the ability for niche manufacturers to offer low-volume production that is both flexible and cost-effective. For instance, our sister publication Additive Manufacturing recently featured the Periscope Case, which is produced via 3D printing with no investment in tooling. In addition, the production quantity can be scaled to the market size.

Marketed as the “poor man’s GoPro,” the Periscope Case converts smartphones into an action camera. The case is manufactured for the startup Defox LLC on HP’s Multi Jet Fusion 3D printing platform by RapidMade of Tigard, Oregon.

Check out the below video from Additive Manufacturing’s Pete Zelinski where he showcases the product. Learn much more in his article about the case.

Additive Manufacturing explores how manufacturers are applying 3D printing to make tooling, molds, functional prototypes and end-use parts. Subscribe.

Related Content

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its business — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

-

Xenia 3DF Materials for FFF Printing

Xenia filament materials for fused filament fabrication.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).