BASF's Chemical Recycling Process Produces Virgin Grade Material for Food-Contact Approved Quality

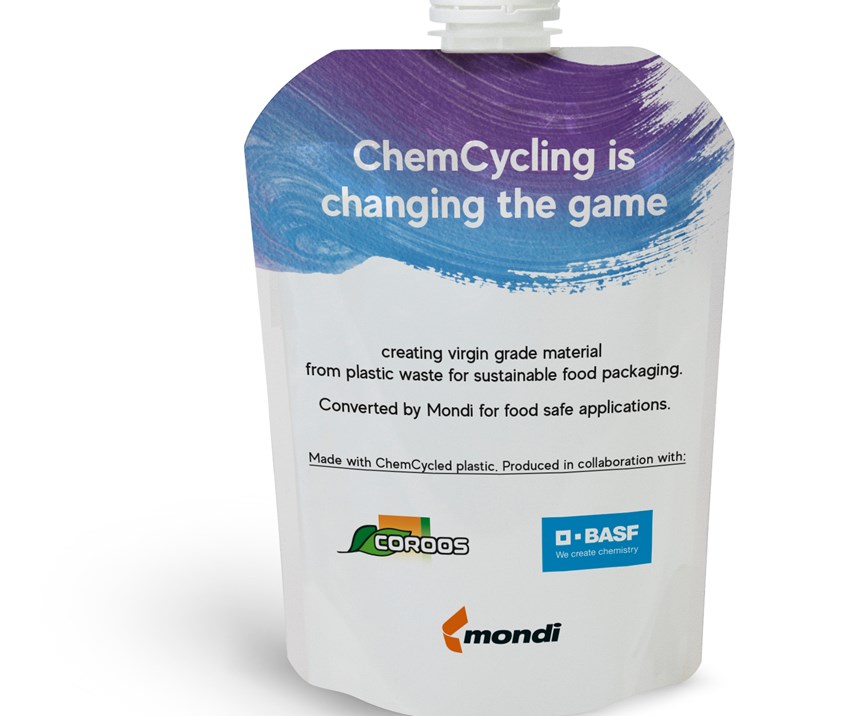

Creating flexible packaging such as stand-up pouches from virgin-grade material derived from plastic waste is taking a step closer to reality in BASF’s ChemCycling project.

I recently reported that new market studies show that the growth of stand-up pouches for a variety of packaged products—ranging from dry, frozen and liquid foods, to non-food product—is expected to continue to grow at a strong pace. I also noted that the all-PE (mono-material) structures have been gaining a lead due to their recyclability advantage, and we have a feature article slated for our November issue on this topic.

Yet another trend that is also gaining commercial attention is the emergence of stand-up pouches with post-consumer recycled (PCR) content derived from mechanical recycling. Take the latest introduction from Cincinnati-based flexible packaging provider ProAmpac. Last year, the company launched its QuadFlex all-PE pouch (a fully recyclable HDPE blend) with a How2Recycle logo with instructions to consumers for packaging a variety of products ranging from pet food to lawn & garden, cereal and salty snacks.

Just last month, ProAmpac unveiled the production of a high-barrier stand-up pouch made which has PCR content for Nut Butter Covered Nuts from Justin Gold. ProAmpac’s market segment manager Nathan Klettlingertold me that this pouch uses PE as a sealant layer with 40% PCR content—or, 25% of the total structure. He noted that they can also PCR content to the PET print web which could increase the total PCR content up to 50%—assuming a 2.5 mils structure and no zipper.

Yet a third trend emerging is the inclusion of PCR content derived from chemical recycling. One example recently brought to our attention is the work spearheaded by BASF and industry partners as part of the company’s ChemCycling pilot project.

Working with the U.K.-based Mondi Group, a major global packaging and paper manufacturer Mondi and Dutch family-owned company COROOS, one of the biggest European companies in the preservation of fruits, vegetables and pulses for premium A-brands and private label products, BASF announced that in a state-of-the-art pilot project, they produced a stand-up pouch that is safe for food contact partly made with raw material which was derived from chemically recycled plastic. Until now, recycling plastic has chiefly been mechanical, limiting the scope of plastics that can be recycled and limiting the number of products that can be created with recycled material, in particular for the strict legal European regulations in place for food packaging.

Mondi believes that packaging should be sustainable by design, using paper where possible, and plastic when useful. For food protection and extending shelf life, plastic is often the best choice because of its barrier properties. These requirements make it difficult to use mechanically recycled plastic due to potential impurities and plastic flaws that can occur in the layers, limiting the applicability for food contact. Said Christoph Gahn, who is responsible for the nylon business at BASF, “BASF is working on advancing the chemical recycling of plastic waste, because this will make it possible to process and reuse plastics that are currently difficult to recycle such as mixed plastics. This prototype packaging which is based on pyrolysis oil derived from waste plastic shows that the life cycle of consumer plastics, including multilayer packaging, could become a closed loop.”

As a leader in the flexible packaging market, Mondi partnered with BASF to produce this virgin grade material into a multi-layer laminate for food packaging for COROOS private label products and their own A-brand Servero. In the manufacturing, 100% of the fossil feedstock was replaced by pyrolysis oil derived from mixed recycled material for one of the inner layers (oriented nylon 6, OPA-12 mm). In total 12% of the packaging weight is made of ChemCycled material. The recycled material was allocated via a certified mass balance approach.

Sustainability Manager for Mondi Consumer Packaging Graeme Smith- explained further,“It is important to show proof of concept when establishing breakthrough developments, and for chemical recycling it is an essential part of the roadmap to commercializing this process in the future.”

Sustainable solutions are not just a priority for Mondi, but across the entire value chain: “COROOS is partnering in this project because we care about sustainability and are looking into different options to improve our footprint, e.g. by using packaging from recycled materials, packaging materials being recyclable and/or by being re-usable,” shared COROOS marketing manager Elke Schroevers.

With this development, the way is paved for plastic waste to become a new resource for flexible packaging while replacing fossil fuels. Physical samples have been produced during a recent line trial by COROOS and were presented at FachPack in Nuremberg, Germany September 24-26th.

Related Content

Prices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MoreDensity & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More