Density & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Polyethylene has been around as a commercial material for a little over 70 years. It was one of the early developments in synthetic thermoplastics. Given its long history, it could be assumed that we understand everything there is to know about this polymer. However, I am constantly surprised by the confusion that exists regarding two key properties that describe the properties and performance of PEs. These are the density and the molecular weight. Molecular weight is typically captured by a number known as melt index or melt flow rate. The higher the melt index of the material the lower the average molecular weight of the polymer.

If you ask a processor what type of PE they are running, a typical response will be, “I’m running a 7-melt, 953 material.” Translation: a material with a nominal melt index of 7 g/10 min. and a density of 0.953 grams/cm3. These two numbers convey a lot of information regarding the balance of properties that can be obtained from parts molded in this material. For example, this particular selection would be typical for a 5-gal pail. These parts require a balance of creep resistance and toughness so that when stacked they do not collapse under their own weight and when dropped they do not crack.

While molders may know through experience what works for a given application, they often do not know why. They tend to think of melt index as a gauge of processability and they often believe that molecular weight and density are linked, when in fact they can be varied independently of one another. Part of the confusion is understandable. The ability to specify density as a property of a material may be unique to polyethylene. For most polymers, unless they are filled, the density is essentially an inherent property of the material. The density of blends may vary as a function of the ratio of the two materials being blended; but here again, once the recipe is fixed this property is a fundamental aspect of the product.

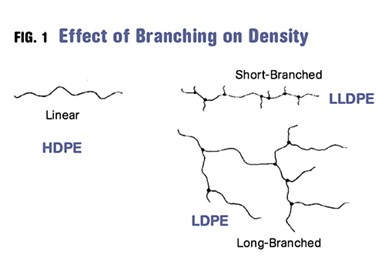

Not so with PE. Because of the ability of the material to form either linear or branched structures, the density of polyethylene can vary from a low of 0.857 g/cm3 to a maximum of 0.975 g/cm3. If you held two parts of the same design made from materials representing these two extremes you could readily tell the difference. The higher-density part would be much stronger and stiffer and would also be more likely to fail an impact test, particularly if it were conducted at a low temperature.

While molders may know through experience what works for a given application, they often do not know why.

If you weighed the two parts you would also notice that the part made from the higher-density product was heavier. And this is where the confusion comes in. Many people assume that the weight of the part is related to the weight of the individual polymer molecules that make up the part. However, the two are not related at all. If you look at enough PE data sheets you will see that there are low-density materials with both high and low values for melt index and there are high-density materials with this same range of melt index values. If the two properties were linked this would not be possible.

Schematics show what we imagine molecules of HDPE, LLDPE, and LDPE to look like.

Figure 1 helps to illustrate the difference. It shows schematics of what we imagine molecules of HDPE, LLDPE, and LDPE to look like. A very linear PE chain can closely approach other PE chains of similar structure, thus creating a very densely packed network. This results in a high-density material that is relatively strong and stiff.

But this network tells us nothing about the length of the individual molecules. They may be quite long or relatively short. The same is true of the branched structures. The branching keeps the individual chains farther apart, reducing the density and the load-bearing properties of the material. But here again, the individual chains may be quite long or quite short. If the chains are long the melt index will be low, the material will exhibit a higher melt viscosity and greater melt strength, and the resulting molded part will have better impact performance compared with a material of comparable density that is made up of shorter chains.

The fact that these two properties are independent variables is both good and bad news. The good news is that it offers the possibility for a very wide array of processing and performance options and is one of the reasons that polyethylene is such a versatile material. The bad news is that it makes understanding the relationship between these properties and part performance more difficult.

Sometimes these two properties work together to improve a particular aspect of performance while at other times they work in opposition to one another. For example, creep resistance is improved by increasing either density or molecular weight. However, improving toughness is accomplished by increasing molecular weight or decreasing density. If the melt index of the pail material we discussed above were raised to make processing easier, the impact performance might decline to a point where the parts would not pass standard tests performed by the container industry. If the density of the material were then reduced to restore this lost toughness, a change of even a few thousandths might cause the creep resistance to become unacceptable. The right combination for a given application is critical.

Sometimes these two properties work together to improve a particular aspect of performance while at other times they work in opposition to one another.

This was illustrated more than a decade ago when manufacturers of small gas tanks for products such as lawnmowers and snowblowers changed the density of the polyethylene they were using from 0.946 to 0.952 g/cm3 when the original material became unavailable. The melt index remained the same at 4 g/10 min. Initially there were no apparent problems with the new material.

However, over time certain designs showed an increased tendency to crack while in use. This prompted a large recall and the experience has had lasting effects on the regulations for manufacturing these tanks. It is possible that the loss in toughness brought about by the increase in density could have been offset by a reduction in melt index. But most processors involved in molding the parts deemed the higher-molecular-weight materials to be too difficult to process. It was not until another PE supplier stepped in with a material having a molecular weight and density comparable to the original product that the problem was solved.

So as commonplace as PE may be, this “commodity” material is very complex. Selecting the correct grade from the thousands of commercial options requires a thorough understanding of the interaction between these two properties. The property envelope for this polymer extends from materials that border on elastomers to those that are relatively strong and rigid.

ABOUT THE AUTHOR: Michael Sepe is an independent materials and processing consultant based in Sedona, Ariz., with clients throughout North America, Europe, and Asia. He has more than 45 years of experience in the plastics industry and assists clients with material selection, designing for manufacturability, process optimization, troubleshooting, and failure analysis. Contact: (928) 203-0408 • mike@thematerialanalyst.com

Related Content

First Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreRead Next

Tracing the History of Polymeric Materials: Celluloid

In this series we’ll delve into a discerning look back into the history of our industry and how we all got here.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.jpg;width=70;height=70;mode=crop)