Bill Gates Invests in Low-Carbon Plastics

Pioneer for the conversion of biomass into cellulosic sugar technology can now start to move from lab into commercial use.

Pioneer for the conversion of biomass into cellulosic sugar technology can now start to move from lab into commercial use.

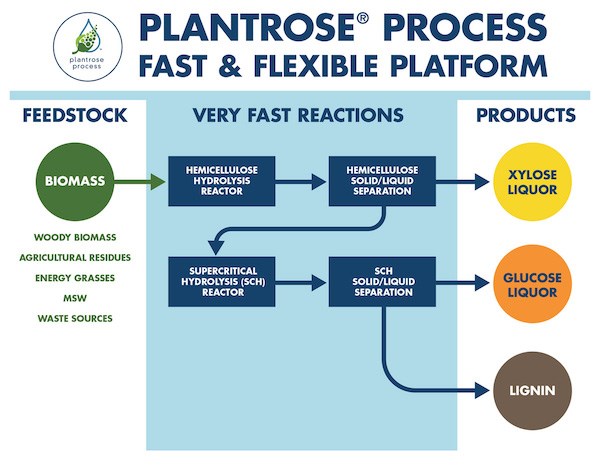

Earlier this year, startup Renmatix, Philadephia, a leading licensor for the conversion of biomass into cellulosic sugar and a commercial partner of NewBio, patented its Plantrose Process that can lead to cost-effective production of industrial sugars on a commercial scale as an alternative to petroleum-based polymers in a range of industrial processes. (Led by Penn State University, NewBio is a regional network of universities, businesses, and government organizations dedicated to building robust, scalable, and sustainable value chains for biomass energy in the Northeast.)

Now, Renmatix has secured a $14-million investment from Microsoft co-founder Bill Gates, which will allow it to begin the technology’s transition from the lab to industrial use. Before the U.N.’s Paris climate talks earlier this year, Gates corralled 28 high-profile investors to form the Breakthrough Energy Coalition and committed them to invest in low-carbon energy innovation to save the planet.

Said Gates, “To effectively address climate change, we need to develop an energy infrastructure that doesn’t emit greenhouse gas and is cost competitive. A critical component in this effort must be to decarbonize the industrial sector. Another is the possibility of cost-competitive biofuels. Renmatix provides and innovative process that is an exciting pathway to pursue.”

Menwhile, Belgium’s Total (U.S office in Houston), a global energy and back-integrated polyolefins and PS conglomerate, joined Gates in expanding its initial 2015 investment in Renmatix by signing a licensing agreement with the company for 1-million tons (2-billion/lbs) of annual cellulosic sugar production capacity, at Total’s discretion to build corresponding facilities.

The license represents significant revenue potential for Renmatix, extending over the agreement’s lifetime. “Our ambition is to become the responsible energy major. We want to make low-carbon businesses a profitable growth driver accounting for 20% of our portfolio in 20 years’ time. Meeting these goals in what has led to setting-up and expanding our collaboration with Renmatix,” Total Chairman and CEO Patrick Pouyanne said.

Renmatix’s Plantrose process uses supercritical water to reduce costs in conversion of biomass to cellulosic sugars, the critical intermediary for second-generation biochemical and biofuels. With faster reactions and virtually no associated consumable-expenses, Renmatix’s supercritical hydrolysis is said to economically enable a multitude of renewable process technologies and help access the market for ‘high-volume, low-cost, broadly-sourced’ cellulosic sugars. From this industrial sugars’ foundation, the company is expanding its product portfolio with additional bio-building block intermediates, including Omno polymers and crystalline cellulose.

The new investment in commercializing Plantrose is expected to help in the drive towards the first wave of Renmatix licensees building Plantrose-enabled biorefineries in diverse global markets like Canada, India, Malaysia, the U.S. and elsewhere. In parallel, such activity will facilitate further market development in downstream bioproduct applications. Renmatix CEO Mike Hamilton:

“This investment from Gates and Total together shows recognition of our technological achievements, and magnifies our commercial momentum. That acknowledgement and Total’s signing of the million-ton license are compelling indicators of our Plantrose technology’s maturation toward biorefinery scale.”

Related Content

How to Optimize Your Molds and Hot Runners for Processing Bioresins

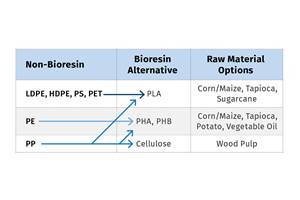

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

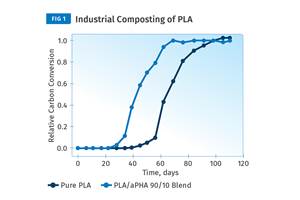

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More

.png;maxWidth=300;quality=90)