'Clean, Sustainable' Carbon Black Production On Our Shores

Monolith's carbon black process, which uses natural gas as feedstock, will now be applied to a full-scale manufacturing facility in Nebraska.

Throughout most of the 20th century, North America was the leading producer of carbon black. By 2012, North American capacity had dropped to a mere 12% of the global capacity, while China’s had risen to 38%. One company is looking to shift the production of carbon black from being less reliant on the utilization of petroleum oil; first, in the domestic market and then globally. In fact, Monolith Materials (formerly Boxer Industries) believes that its proprietary process technology has the potential to reestablish North America as the leading global producer of carbon black.

The Redwood City, California firm produces both standard ASTM grades of carbon black as well as highly customized performance grades for a broad range of applications. In plastics alone, these range from colorants in consumer and industrial goods to UV absorbers in pipe and agricultural films to electrically conductive grades used in electrical cables and various components of high-volume consumer electronics. Carbon blacks have long been used as reinforcing agents and fillers in tires and other rubber products, batteries, and as pigments in inks, paints and toner.

Monolith uses natural gas as feedstock in its process instead of crude oil or coal-tar as in conventional processes. Since mid-2014, the company has been operating a pilot plant using its technology to convert pipeline grade natural gas using grid electricity into valuable carbon black and hydrogen. Located at its Redwood City site, the Seaport Plant serves as Monolith’s industrial demonstration facility and represents the first new carbon black plant to be permitted and build in the U.S. in the past 30 years, because of environmental regulations. On-site lab facilities also allow for grade evaluation and tuning, as well as ongoing applications development.

As noted above, a coproduct of Monolith’s manufacturing process is plentiful hydrogen. This valuable industrial gas is used in a range of industries including petroleum refining, clean-power generation, and chemicals. It was this that led to Monolith establishing what appears to be a first-of-its-kind partnership with the Nebraska Public Power District (NPPD), Nebraska’s largest electric utility. NPPD plans to replace an existing coal-fired boiler at its Sheldon Station plant in Hallam, Nebraska with one that will use hydrogen, produced by Monolith’s new full-scale carbon black manufacturing facility, to generate electricity.

Construction of Monolith’s facility is commencing this year, with initial production capacity scheduled online in 2016, and full production capacity on line in 2019. It is being build adjacent to the Sheldon Station so NPPD can easily access the hydrogen. When burned, the hydrogen fuel produces zero greenhouse gas emissions. Through this collaborative project, NPPD is expected to reduce CO2 emissions at Sheldon Station by 1.1 million tons/yr. The new boiler, using hydrogen as a fuel, will continue to be capable of generating 125 megawatts of electricity for NPPD’s customers. The conversion is also expected to result in a dramatic reduction in other types of air emissions, and also aid in NPPD’s maintaining service as a low-cost energy producer.

The facility will result in hundreds of new high-tech manufacturing jobs in that region. In their joint announcement, Pat Pope, president and CEO of NPPD noted that the Sheldon Station has always been “a place of firsts”—the first nuclear plant in Nebraska and now the first utility-scale hydrogen powered generator. Said Monolith’s co-founder and CCO Robert Hanson, “Together, Monolith and NPPD are helping reduce pollution, while still adding jobs and maintaining energy production. Additionally, Monolith is bringing the first cleanly made carbon black plant to the U.S., which will help our country grow this important industry and expand America’s manufacturing economy.”

Related Content

Ineos Nitriles Launches Biobased Acrylonitrile

The company’s Invireo is said to deliver a 90% lower carbon footprint compared to conventionally produced acrylonitrile.

Read MoreBorealis and Partners Move Forward with Crosslinked PE and PP Pipes Based on Renewable Feedstock

The company’s partnerships in these new drop-in solutions significantly advances carbon footprint reduction.

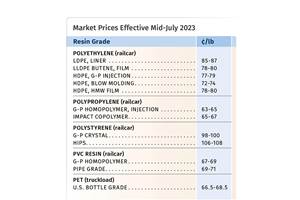

Read MorePS Prices Plunge, Others Appear to Be Bottoming Out

PS prices to see significant drop, with some potential for a modest downward path for others.

Read MoreEV Chargers Made From Renewable PC

SABIC is enabling Charge Amps to manufacture electric vehicle (EV) chargers with a housing made from certified renewable PC, a first for the industry.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More