‘Engineering’ Plastic Structure for Thermal Conductivity

U. of Michigan researchers’ process is a major departure from past approaches to rendering thermal conductivity to plastics.

Over the last several years, achieving thermal conductivity in plastics in applications such as high-power density electronic devices, automotive cooling systems, and batteries, where heat accumulation can have deleterious effects, has been achieved by blending the plastics with highly thermally conductive fillers such as metal or ceramic particles, carbon nanotubes (CNTs), or graphene flakes.

The key challenge, however, has been the large volume fraction of such fillers required to achieve appreciable enhancement in thermal conductivity, which often leads to undesired optical or electrical properties, increased weight, high cost, and at times loss of the easy processability typically associated with plastics.

Plastics are replacing metals and ceramics in many places, but they’re such poor heat conductors that nobody ever considers them for applications that require heat to be dissipated efficiently.

Help could be on the way thanks to a team of researchers from the materials science and mechanical engineering sectors of the University of Michigan (U-M), Ann Arbor, Mich. “Plastics are replacing metals and ceramics in many places, but they’re such poor heat conductors that nobody ever considers them for applications that require heat to be dissipated efficiently….We’re working to change that by applying thermal engineering to plastics in a way that hasn’t been done before,” according to Jinsang Kim, U-M material science and engineering professor.

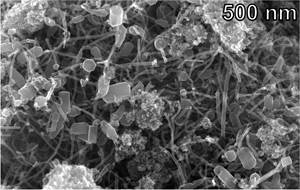

Representing a major departure from previous approaches, this technique uses a process that engineers the structure of the material itself. Plastics are made of long chains of molecules that are tightly coiled and tangled like a bowl of spaghetti. As heat travels through the material, it must travel along and between these chains—an arduous, roundabout journey that impedes its progress.

The U-M team—which includes associate professor of mechanical engineering Kevin Pipe, mechanical engineering graduate researcher Chen Li and materials science and engineering graduate student Apoorv Shanker—used a chemical process that expand and straighten the molecule chains—essentially giving heat energy a more direct route through the material.

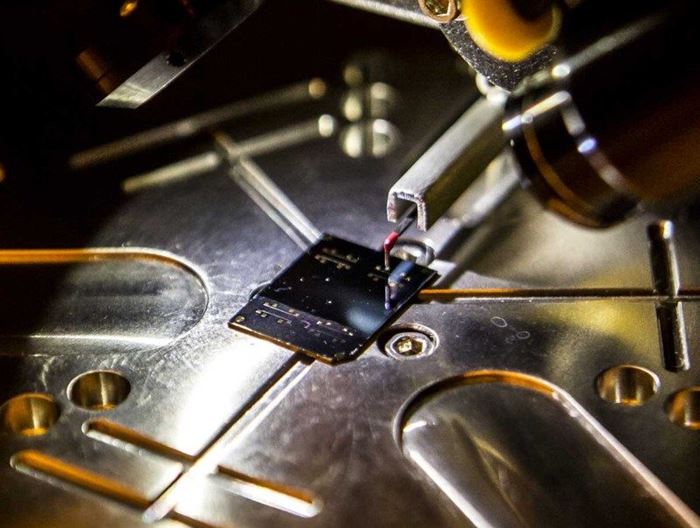

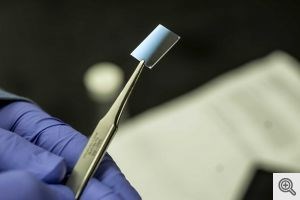

The team started with a typical amorphous plastic—in this case, a weak polyelectrolyte, polyacrylic acid (atactic PAA). First, the polymer is dissolved in water, then electrolytes are added to the solution to raise its Ph, making it alkaline. The individual links—monomers—in the polymer chain take on a negative charge, which causes them to repel each other. As they spread apart, they unfurl the chain’s tight coil. Next, the water and polymer solution is sprayed onto plates using a common industrial process called spin casting, which reconstitutes it into a solid plastic film.

The uncoiled molecule chains now make heat easier to travel through the plastic. A secondary benefit found: the process stiffens the polymer chains and helps them flock together more tightly, making them even more thermally conductive. Noted Shanker, “Polymer molecules conduct heat by vibrating, and a stiffer molecule chain can vibrate more easily…think of a tightly stretched guitar string compared to a loosely coiled piece of twine. The guitar string will vibrate when plucked, the twine won’t. Polymer molecule chains behave in a similar way.”

Representing a major departure from previous approaches, this technique uses a process that engineers the structure of the material itself.

This team endeavor can have important consequences due to the large number of plastics applications in which temperature is important, according to Pipe. “Researchers have long studied ways to modify the molecular structure of polymers to engineer their mechanical, optical or electronic properties, but very few studies have examined molecular design approaches to engineer their thermal properties….while heat flow in materials is often a complex process, even small improvements in the thermal conductivities of polymers can have a large technological impact.”

Next for this team: Making composites that combine the new technique with several other heat dissipating strategies to further increase thermal conductivity. Also, they are exploring how to apply the concept to other types of polymers. A commercial product is likely to be a few years away. Concludes Li, “We’re looking at using organic solvents to apply this technique to non-water soluble polymers…but we believe the concept of using electrolytes to thermally engineer polymers is a versatile idea that will apply across many other polymers.”

One thing is for certain, according to industry studies, the annual market demand growth for thermally conductive plastics appears to be in the double-digit range.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More