PE & PP Prices Down

A buyer’s market for both polyolefins could continue though this quarter and into the fourth.

As we were approaching the end of the first week of August, it appeared that prices of both polyolefins had dropped, in both cases nixing out price hikes that took place in second quarter. Ample supplies, slowed domestic and global demand and lower feedstock costs are all key drivers in this pricing trajectory. This according to the latest reports from two of our industry resin pricing pros: David Barry, senior editor at Houston-based PetroChemWire (PCW); and CEO Michael Greenberg of the Plastics Exchange in Chicago.

▪ PE: Despite suppliers being out with a 3¢/lb price hike in the June/July time frame, industry analysts and certainly processors were expecting the opposite—price concessions of about the same amount that would effectively nix out the April 3¢ price hike, the one and only increase of 2019. Mixed industry reports had it that at least some processors had seen a 3¢/lb decrease in June and that the rest would see it in July. PCW’s Barry recently reported that PE suppliers had indeed lowered contract prices by 3¢/lb by July’s end.

And Greenberg reported as follows: “July contract pricing became a little more clear and most PE market participants should see a 3¢/lb mark down. Although the relief is welcomed, many will continue to push for further decreases as spot levels have declined even more. If you’ve been able to supplement your purchasing through the spot market you have done well this year.”

Barry ventured that suppliers are generally looking towards demand strengthening in fourth quarter, but that further new capacity still coming on stream in the Gulf Coast fromExxonMobil Chemical, LyondellBasell Industries, Formosa Plastics, and Sasol could outweigh a stronger demand pull.

Barry also cited broader economic concerns noting the manufacturing index from the Institute of Supply Management (ISM) indicated manufacturing growth in July was the slowest in nearly three years. The ISM month-to-month survey, based on input from more than 300 manufacturing purchasing agents, also showed lower production and new orders for the plastics and rubber processing industry.

In addition, Barry reported that international buyers were pushing for further price cuts in August, and that grades like HMWPE film grades and HDPE injection molding grades showed no letup in downward pressure. “HMWPE film prices dipped below HDPE BM amid ample supply of the film grade and new environmental regulations in Latin America that were said to be weighing on the demand outlook for plastic bags.”

▪ PP: As noted in an earlier blog, PP prices in July increased by 0.5¢/lb, decoupling for the first time in a couple of years from propylene monomer contracts which settled up 1.5¢/lb—essentially translating a 1¢/lb margin contraction for suppliers. This slight upwards move followed the 4¢/lb June decrease which nixed out May’s 4¢/lb increase, the only one for 2019. Moreover, PP prices dropped by about 24¢/lb between November 2018 and March 2019.

According to PCW’s Barry, expectations for August propylene monomer contracts were generally for flat to slightly lower. “Butane cracking, soft PP demand and high propylene inventories were mentioned as bearish factors for the propylene market.”

Moreover, Barry reported that the July 31 explosion and fire at the ExxonMobil Baytown, Texas olefins plant created new uncertainty for the market, as the site houses several PP units as well as monomer supply. “Initial indications were that no significant disruptions to resin deliveries were expected. Overall, operating rates in the PP industry have been healthy this summer, and core demand in July was described as lackluster, especially in the nonwoven and automotive sectors.”

Greenberg reported the spot PP market as active throughout July and into August. “After rallying early in the month as spot monomer costs jumped, PP prices fell under pressure as upstream costs started to ease; however, overall pricing for spot homopolymer and copolymer PP added a penny this week following the fire at Exxon's Baytown plant. Some of this week’s orders were for business as usual, other customers procured material to bridge their late railcars, while some saw supply risk and added a buffer to their resin inventories. Material availability was still good, although not on par with earlier in the month.”

Barry reported that LyondellBasell was reportedly building inventory for a planned outage at its Bayport, Texas PP facility, scheduled to begin later this month, and that Formosa was likely to have minor maintenance outages scheduled during August as well.

Related Content

Record Reshoring Rates in 2022

Reshoring and foreign direct investment (FDI) in the third quarter marked their highest ever level, eclipsing the previous record set in the second quarter of 2022.

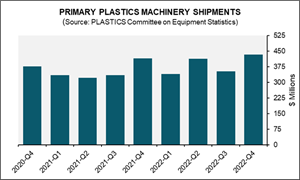

Read MorePlastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

Read MoreChemical Recycling Process for Crosslinked PE

Borealis announces capability to produce recycled PE for use in wire & cable, infrastructure industries.

Read MoreArtificial Intelligence Enables Smarter Sourcing

Westfall Technik has adopted Arkestro’s predictive procurement software to wring savings and more reliable deliveries from a historically challenging supply chain.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More

.png;maxWidth=300;quality=90)