Multiple Frame Styles With New Highly-Transparent Nylon Eyewear

Developed by Evonik and Tungfung, Implex preform technology offers greater flexibility for eyeglasses.

Developed by Evonik and Tungfung, Implex preform technology offers greater flexibility for eyeglasses.

An innovative technology for manufacturing eyeglass frames with greater flexibility has been developed by Germany’s Evonik in collaboration with eyewear manufacturer Tung Fung Intl., headquartered in Hong Kong. Called Implex, the technology is based on the use of Trogamid, highly-transparent and high-performance nylon.

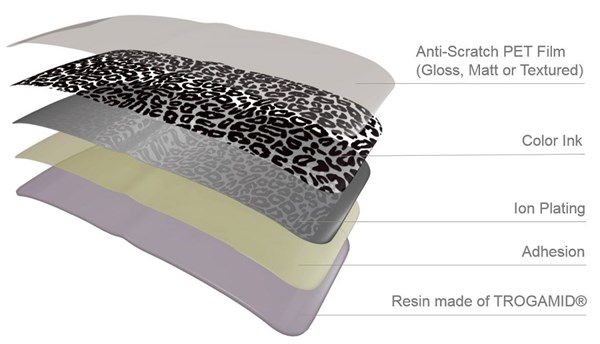

Implex involves cutting the finished frames from a single-curved preform, in this way eliminating the machining and finishing steps after injection molding. The preform is made of multiple functional layers comprising the base frame made of Trogamid, the adhesive and coating layers, or the scratch-resistant film. Implex boasts easy handling, excellent productivity and the ability to customize in a variety of colors, textures, and patterns.

“The whole process is design-printing-injection-cutting. Through this solution, it is more easy to realize varied designs and shorten new developments compared with normal frame production,” explains Janusz Berger, communications manager for Evonik Corporation's High Performance Polymers. Whereas with the traditional method a new mold for each different style of frame is required, Implex allows designers to directly cut into shape a desired frame design. Also, traditional method entails the important post-coating treatment, which Berger says, is not easy to control.

Each Implex sheet features one Trogamid resin layer, explains Berger. Evonik offers two material “solutions”. Transparent Trogamid CX9704 used for the base frame is said to allow manufacturers to vary the shape of the products due to its pliability. It features crystallites that are so small that they do not scatter visible light, so the material appears transparent to the human eye—a property knows as microcrystallinity.

This microcrystalline structure has been shown to retain important properties such as stress-cracking resistance—without clouding. Also, because the degree of crystallinity is so negligible, there is no adverse effect on the shrinkage behavior of molded parts—as is the case with amorphous nylons.

Meanwhile, Trogamid CX9711 can provide a second structural layer. It is touted for its excellent processing characteristics and high resistance to chemicals.

Related Content

-

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

-

New Cap for Child-Resistant Pill Bottles Is Senior-Friendly & Saves Resin

Exclusive lightweight cap design can be removed simply pushing down on the center. No gripping or twisting needed.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)