Survey: Open Ecosystem is Important to Advance 3D Printing at Scale

About 162 managers and executives from large manufacturing companies across the world completed the survey on their current experiences, challenges and trends with 3D printing for production manufacturing.

Essentium recently released an interesting survey focused on the current and future use of industrial 3D printing. The study reveals that virtually all (99%) manufacturing executives surveyed believe an open ecosystem is important to advance 3D printing at scale. While 85% of manufacturers reported that industrial-scale AM has the potential to increase revenue for their business; 22% said their 3D printing efforts have resulted in vendor lock-in that limits flexibility.

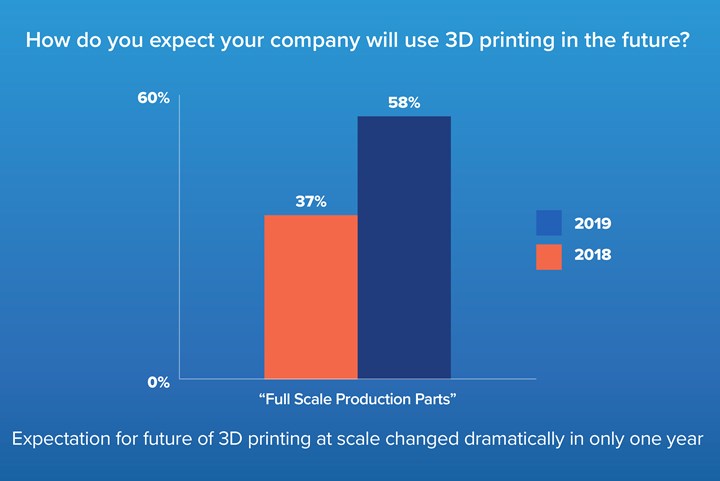

As the technology obstacles around economics, scale, strength and speed of production fall away, the number of manufacturers using 3D printing for full-scale production has doubled compared to last year (40% in 2019; 21% in 2018). According to the survey, manufacturers are now demanding open ecosystems to overcome system inflexibility and use the materials of their choice – 50% of companies said they need high quality and affordable materials to meet the growing demand for industrial 3D printed parts.

An open market focused on developing new materials and better and faster machines is the only way for manufacturers to unlock new applications and new business opportunities. With this approach, the future belongs to the customer, not to the OEM.

Essentium says that an open additive ecosystem will see more partnerships focused on giving customers greater control of their innovation, more choice in materials, and industrial-scale production at ground-breaking economics.

Essentium operates an open 3D printing ecosystem, which was developed in collaboration with multinational chemical company BASF and 3D software developer Materialise NV. The company believes demand for this is a clear indication that an open ecosystem approach is addressing unmet needs in the industrial additive market.

Blake Teipel, CEO and Co-founder, Essentium, said: “At Essentium, we strongly believe that an open ecosystem will be key to the evolution of additive manufacturing. Being locked into proprietary solutions that limit flexibility and choice is no longer an option if 3D printing is to become a serious contender as an industrial process for end-use products. An open market focused on developing new materials and better and faster machines is the only way for manufacturers to unlock new applications and new business opportunities. With this approach, the future belongs to the customer, not to the OEM.”

Related Content

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.