Arevo to Produce 3D-Printed Carbon Fiber Unibody Bike Frames

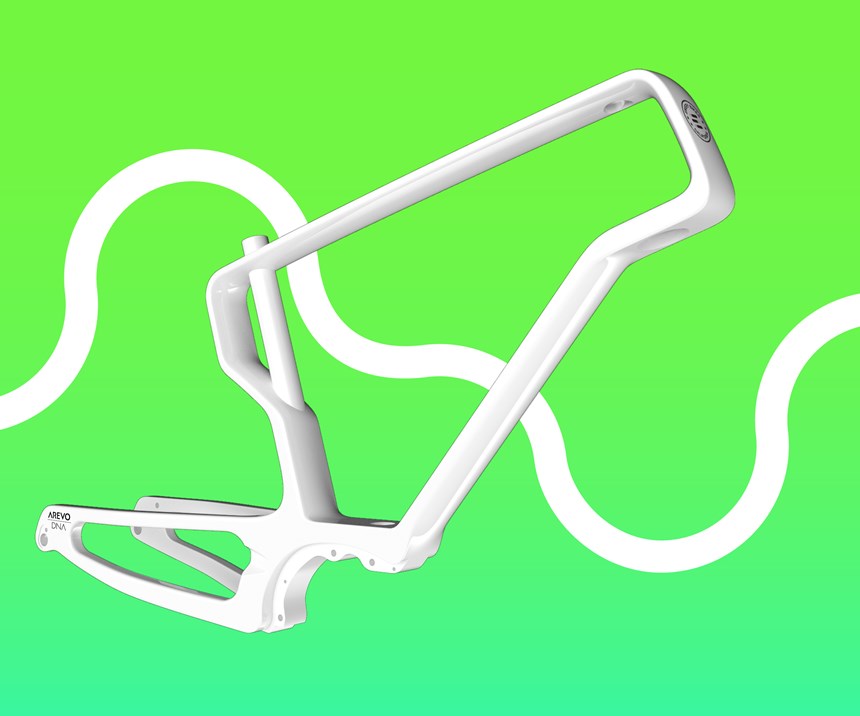

The Arevo frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together.

Silicon Valley-based Arevo announced a partnership with boutique bike manufacturer Franco Bicycles to deliver a reported “world’s first” 3D printed, continuous carbon fiber single-piece unibody frame for a new line of eBikes Franco that will sell under the “Emery” brand.

Arevo DNA additive manufacturing (AM) technology features patented software algorithms enabling generative design techniques, free-motion robotics for “True 3D” construction, and direct energy deposition for virtually void free construction all optimized for anisotropic composite materials. For instance, the Arevo bike frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together.

The Arevo DNA AM process takes the design and final manufacture of a bike frame from 18 months to just a few days at a significant reduction in product development costs. The frames are in production now at Arevo’s new multi-purpose facility in Milpitas.

The company believes that this represents several breakthroughs for bicycle manufacturers, with implications for other industries as well including true serial, volume production of AM-made composite parts. These parts are composed with thermoplastic materials, which are tougher, durable and recyclable, as compared to brittle and non-recyclable thermoset materials.

“This is the first composite additive-manufactured bike frame and it represents an important milestone for the AM industry as Arevo is delivering on the promise of on-demand manufacturing of composite parts in volume now,” says Hemant Bheda, Arevo Co-Founder and Chairman.

Related Content

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

.png;maxWidth=300;quality=90)