Joint Project Will Demonstrate Recycling Polyamide 66 Using Microwave Technology

Materials producer Asahi Kasei and recycling technology developer Microwave Chemical announced a joint chemical recycling project.

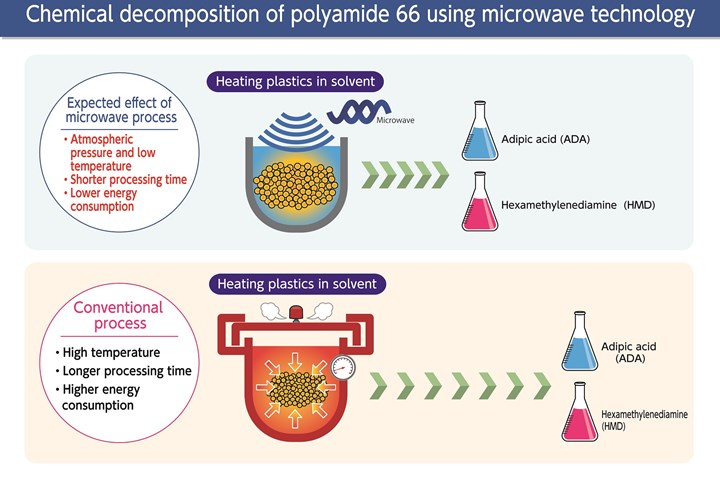

Asahi Kasei and Microwave Chemical have launched a joint demonstration project with the objective of commercializing a chemical recycling process for polyamide 66 using microwave technology. The process utilizes microwaves to depolymerize PA66 and directly obtain hexamethylenediamine and adipic acid, the six-carbon monomers it is named for. The monomers can then be used to manufacture new PA66. In the demonstration, scraps from manufacturing and post-use waste material of PA66 for airbags and automobile parts are depolymerized.

The use of microwaves is expected to reduce energy needed for depolymerization.

Photo Credit: Microwave Chemical

Since 2021, laboratory scale studies have confirmed the high-yield depolymerization of PA66 using microwaves, as well as subsequent processes for separation and purification of the monomer products. Microwave’s proprietary PlaWave technology operates at lower temperatures and has lower energy requirements than conventional processes for depolymerization of PA66.

Asahi Kasei currently produces Leona 66, an engineered PA66, from fossil fuel-derived hexamethylenediamine and adipic acid, with automotive and electronics applications.

Benchtop demonstration trials are planned for 2024, with a decision on commercialization expected by 2025. Microwave Chemical is also working to expand the types of materials its PlaWave technology can be used to chemically recycle, including PMMA, PU foam, automotive shredder residue, and others.

Related Content

-

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

Thermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

.png;maxWidth=300;quality=90)