Vinyl Institute Announces Grant Program to Accelerate PVC Recycling

Up to $3 million will be granted over three years to projects aimed at post-consumer recycling of PVC.

The Vinyl Institute announced the initiation of Viability, the first grant program aimed at promoting recycling of post-consumer PVC. Up to $1 million in funds will be granted each year over the next three years from four PVC resin manufacturers in the U.S.: Formosa, Oxy, Shintech, and Westlake.

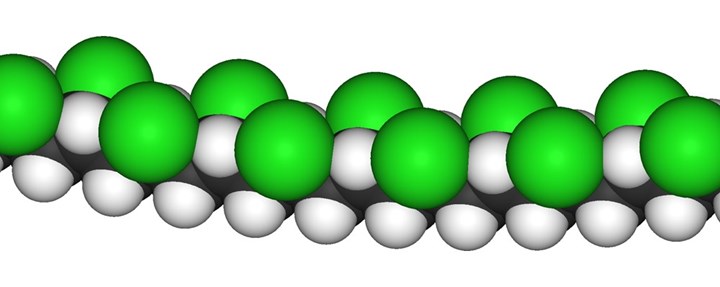

Polyvinyl chloride. Vinyl Institute members produce PVC, vinyl chloride monomer, or associated additives and modifiers.

Photo Credit: Public Domain

Individual grants issued through the Viability program are available to qualifying industry collaborations such as trade associations, material recovery facilities, construction and demolition waste facilities, recyclers, or colleges and universities in amounts up to $500,000. The funds may be used for the purchase of equipment, process investments, research and development, educational programs, and program management that supports long-lasting and sustainable recycling of vinyl products. A seven-member grant committee of the Vinyl Institute will choose recipients of the grants.

Viability will select programs that support post consumer PVC recycling.

Photo Credit: Vinyl Institute

The first round of grant applications is due on March 1, 2023. The Vinyl Institute will announce the awarding of grants no later than 60 days after a grant application deadline.

The Vinyl Institute is a trade organization representing PVC manufacturers. The organization was established in 1982. Last year, the institute published a directory to help consumers find locations that accept PVC materials for recycling.

Related Content

-

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

-

Gerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.