A Processor's Perspective: What's Driving Growth in Heavy-Gauge Thermoforming

Key factors for the progress are innovative materials, advanced automation and precision engineering.

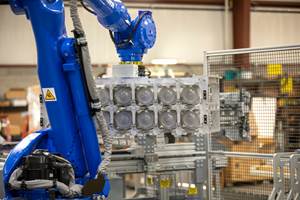

Recognizing that precision and efficiency are key to outstanding production, thermoformers are investing in six-axis robots and scanning technology. Source: Ray Products

The trajectory of heavy-gauge thermoforming has been one of continuous transformation, steered by the relentless pursuit of efficiency and the ever-growing demands for complex parts. Collective strides in this field are shaping a future where efficiency, functionality and environmental responsibility coalesce, marking a significant shift in the capabilities of custom manufacturing. This is a transformative time for thermoforming, with broad implications for the medical, automotive and high-tech industries that rely on these pivotal manufacturing advancements.

Utilizing pressure forming and vacuum forming solutions that exemplify the fusion of technology and craftmanship, manufacturers are able to respond to complex challenges. The production of repeatable, high-quality components is being made possible by minimizing secondary processes, embracing cutting-edge, six-axis robotic trimming and pioneering material innovations.

It’s this balance of meeting intricate design requirements while advancing the efficiency of production that underscores the modern era of heavy-gauge thermoforming. With a commitment to embracing the industry’s trends and refining processes and materials, manufacturers continue to drive the industry toward a future where precision and practicality converge, shaping the landscape of heavy-gauge thermoforming for the better.

Demand for Complex Parts

The balance between aesthetics and functionality is more critical than ever as manufacturers strive to exceed expectations. Today’s manufacturers must adeptly meet the growing need for enhanced efficiency and sophisticated design features such as undercuts, slots and tabs that facilitate seamless interlocking, thereby minimizing assembly time and enhancing the serviceability of devices.

Thermoformers can meet these multifaceted demands by mastering both vacuum forming and pressure forming — complementary branches of thermoforming that together offer a broad spectrum of solutions. Vacuum forming, known for its efficiency and simplicity, draws heated plastic into a mold using a vacuum. This tried-and-true method is well suited for a variety of applications.

On the other hand, pressure forming (a refined adaptation of thermoforming) adds additional air pressure between 80-to-100 psi to force the heated plastic and enabling more intricate designs. This technique takes advantage of pressurized air to push the plastic against the mold, creating parts with highly detailed and complex shapes that boast a crisp mold definition surpassing that which is typically achieved by vacuum forming alone.

The capabilities of pressure forming enable manufacturers to produce parts with the kind of detail usually seen in injection molding but with the benefits of lower tooling costs and faster lead times. By integrating precise details and high-quality surface finishes straight out of the mold, pressure forming often bypasses the need for additional secondary processes, further streamlining production.

Whether it’s the robust simplicity of vacuum forming or the detailed precision of pressure forming, thermoformers can utilize each method's strengths to fabricate custom plastic parts ranging from small and delicate to large, sturdy components of up to 10 in. × 18 in.

Ray Products used Kydex T material to manufacture this medical cart comprised of multiple pressure-formed parts in custom color. Source: Ray Products

Gaining Efficiencies by Minimizing Secondary Processes

In the pursuit of efficiency, thermoformers are making significant strides in reducing the need for secondary processes, a leap forward marked by the adoption of molded-in color techniques. This innovative approach — which involves integrating color directly into the material during the thermoforming process — has revolutionized the production line by eliminating the traditional steps of sanding, masking and painting.

The impact of this advancement resonates through every facet of production. Incorporating color into the very substance of its parts enriches the aesthetic appeal with a spectrum of hues from solid to metallic, while substantially cutting down on manufacturing time. The elimination of postmolding painting reduces handling time, speeds up overall production and minimizes the opportunity for scratches and defects of the paint during assembly or everyday use.

The benefits are just as vibrant from an economic standpoint, as this production process streamlining translates into significant cost savings for customers, often reaching double digits. The efficiency gains also contribute to shortened lead times, providing customers with quicker turnarounds from conception to final delivery, an essential factor in today’s fast-paced market.

Technology at the Forefront: Six-Axis Robots and Scanning

Recognizing that precision and efficiency are key to outstanding production, thermoformers are investing in six-axis robots and scanning technology, underscoring a commitment to excellence that transforms the very nature of their manufacturing process. For example, six-axis robots have been the backbone of Ray Products’ CNC trimming operations for over 15 years, a testament to its foresight in adopting robotic automation early on.

These robotic systems offer a level of precision that manual processes could never achieve, ensuring each part meets stringent quality standards with consistent accuracy. These robots also have capabilities that extend beyond mere trimming. They enable complex, multidimensional movements, enabling the precise execution of intricate cuts and contours on thermoformed parts.

Thermoformers are investing in six-axis robots and scanning technology, underscoring a commitment to excellence that transforms the very nature of their manufacturing process.

Incorporating advanced scanning technologies complements the robotic precision, providing real-time feedback and adjustments that further enhance the quality of each product. Scanning ensures that the specifications of every part are adhered to with meticulous detail, enabling the production of components that seamlessly integrate into the intended device. This combination of robotics and scanning delivers on the promise of high-speed production without compromising quality.

The flexibility afforded by these robotic systems is unparalleled. They adapt to the demands of various project complexities, while their robust design and servo-controlled rotating tables enable quick changes in tooling. This adaptation enables thermoformers to shift between jobs with minimal downtime, thereby ensuring a rapid response to customer need.

Custom-color ABS replaced sheet metal in the covers of these industrial sorters. Source: Ray Products

Material Evolution Addresses New Challenges

A dedication to material innovation is a key driver of progress across industries, particularly noticeable in the burgeoning sector of electric vehicle (EV) production. As EVs continue to surge in popularity, there is a growing demand for materials that meet stringent durability and aesthetic standards, and align with increasingly stringent environmental concerns.

This demand has prompted a strategic shift from traditional thermoset materials toward cutting-edge thermoplastics, a change that thermoformers have been instrumental in leading. In active collaboration with material suppliers, Ray Products is pioneering the development of materials that offer improved performance and enhanced sustainability. These new materials boast advanced finishes with fire-retardant (FR-VO) ratings, compliance with stringent UL 746C standards and features like UV resistance, high-gloss and metallic finishes, all of which can significantly reduce the need for post-molding painting and is a boon for eco-friendly manufacturing practices.

Such innovations reflect a larger commitment to sustainability in the manufacturing process. Materials engineered for molded-in color processes are not only aesthetically versatile but also can be fully recyclable, addressing the eco-conscious market’s demands. Furthermore, this shift to environmentally responsible production practices aligns with global sustainability goals, promoting a greener future across industry borders. This means that the parts created could be repurposed or recycled, minimizing waste and contributing to the health of our planet.

Moreover, the transition to thermoplastics has been underscored by their uniformity and reduced production variability. This translates to components that fit correctly right off the production line, eliminating the need for costly and time-consuming postproduction adjustments like hand sanding or kitting. Such efficiency is pivotal in high-tech industries where quality cannot be compromised and production speed is of the essence.

For medical applications, Ray Products has used materials such as Kydex T (acrylic/PVC alloys) due to its great chemical resistance, UL94 rating and custom color matching with metallics. We also use an injection molding grade of Kydex for the small handheld pieces that are part of their medical devices and carts.

A new material we are using for EV applications is Kydex 1100UV, a weatherable, F1 UL746C, UL94 V0-rated material that also comes in custom colors including metallics.

One example of large parts are these lids for outdoor industrial waste containers made with HMW-PE. Source: Ray Products

Evolving Applications in Thermoforming

Thermoforming, especially the pressure forming technique, is becoming a sought-after method in sectors like medical and high-tech industries. The shift to thermoplastics through thermoforming introduces a level of previously unattainable precision, durability and cost-effectiveness.

The EV manufacturing arena is calling for intricate parts that fit flawlessly into sleek, modern designs and withstand the rigors of outdoor elements and the test of time. By utilizing advanced materials that include flame-retardant properties, UV resistance and robust outdoor weatherability, manufacturers are delivering components that eclipse traditional expectations of quality and functionality.

These innovations extend beyond material selection; they represent a reinvention of the assembly process itself. The ability to create complex, interlocking parts through thermoforming enables easier assembly and enhanced serviceability. Features that once required extensive assembly time, like bosses and fasteners, are now seamlessly integrated, because of the capabilities of heavy-gauge thermoforming. Thermoformers are responding to the current needs and shaping the future of thermoforming, ensuring that the most complex, high-quality parts are within reach for industries embracing this evolution.

ABOUT THE AUTHOR: Jason Middleton is v.p. of sales and development at Ray Products, where he has worked since 2013. He works with customers on projects to determine if they are a fit for the thermoforming process by guiding them with designing, manufacturability and overall process evaluations. He has over 20 years in plastics manufacturing, with experience in vacuum forming, pressure forming, injection molding and the structural foam processes. Contact: 909-740-9037; JasonM@rayplastics.com; rayplastics.com.

Related Content

Manufacturer Helps Clean Up Global Waterways with Reclaimed Plastics

RSP and Oceanworks partnership diverts plastic wastes from waterways for incorporation into new products.

Read MoreUpgraded Former is Faster, More Precise

New features reportedly offer more efficient production of trays, containers, hinged boxes, pallets, blisters, lids and technical products.

Read MoreAn Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

Read MoreBrueckner Group USA Moving to Bigger Space

New facility in New Hampshire will serve the local customer base better and enhance capabilities in the North American market.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More