Adaptive Pressure Reduction Boosts Injection Molding Machine Efficiency

Netstal says its new adaptive system-pressure-reduction option lowers pressure in a machine’s hydraulic system to its optimum point.

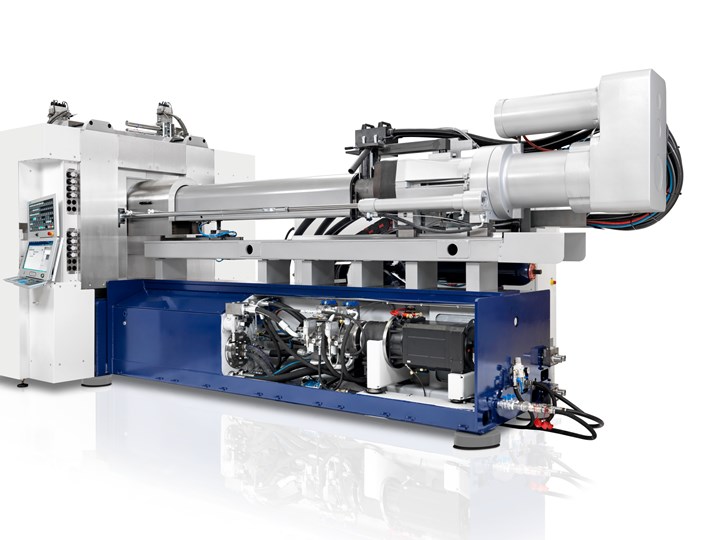

Netstal says its new adaptive system for pressure reduction determines the optimum operating pressure in the hydraulic system for an injection molding machine. Available as a new option for hybrid presses, as well as being retrofittable, the feature lowers power consumption without impacting productivity, serving to lower the machine’s CO2 footprint while generating a speedy return on investment.

Netstal says that to handle peak loads without any problems, the hydraulic system of its hybrid machines is designed for a maximum operating pressure of 250 bar (3626 psi), but, depending on the application, a lower value could also be sufficient. In automatic mode, the adaptive control system determines the optimum point at any time and adjusts the system pressure accordingly.

In addition to using less power, lowering the load on the components can also positively affect machine wear and maintenance intervals. From an investment standpoint, Netstal says that in most cases, the small surcharge for the adaptive system is paid back within a few months, depending on the region and electricity costs. In some regions, investments in more energy-efficient and climate-friendly production facilities are subsidized with government grants.

A Netstal spokesperson told Plastics Technology that in retrofit jobs from a hardware standpoint, accumulators are retrofitted to compensate for pressure differences and achieve a higher lowering potential, depending on the machines. In terms of the impact on power consumption reduction, the spokesperson said that its measurements have shown that, depending on the application, energy savings of approximately 15% are possible.

Adaptive system pressure reduction is available as an option for all hybrid Netstal injection molding machines running the latest aXos version (release 8.6.0).

Netstal’s new adaptive regulation lowers system pressure in the hydraulic system to the optimum point.

Photo Credit: Netstal

Related Content

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

-

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

.png;maxWidth=300;quality=90)