Additive Manufacturing: HP Announces Lower-Cost Jet Fusion 3D Printers for Prototyping—in Full Color

Lower cost, more compact models for low-volume prototyping also introduce full-color 3D printing.

Last month, HP Inc., Palo Alto, Calif., added to its growing line of 3D printers using its exclusive Multi Jet Fusion process with four new, smaller and lower-cost models aimed at design, product development and prototyping. Available in the second half of this year, the new Jet Fusion 300/500 series is designed to produce up to 52 parts of 30-cc volume in 15 hr, while the company’s production-oriented Jet Fusion 3200/4200/4210 models are aimed at volume needs from 130 to 1000 parts/week. The new units have a build volume of up to 7.5 × 13.1 × 9.8 in. vs. up to 15 × 111.2 × 15 in. for the production models. The 300/500 series is also more compact, embodying a one-piece integrated design, while the production models require three separate pieces of equipment for materials and parts handling and cooling. The new units are priced from the “low $50,000s” to the “low $100,000s” range, while the 4200 series starts at around $300,000 for a full system, since most users purchase at least two processing stations in addition to the printer.

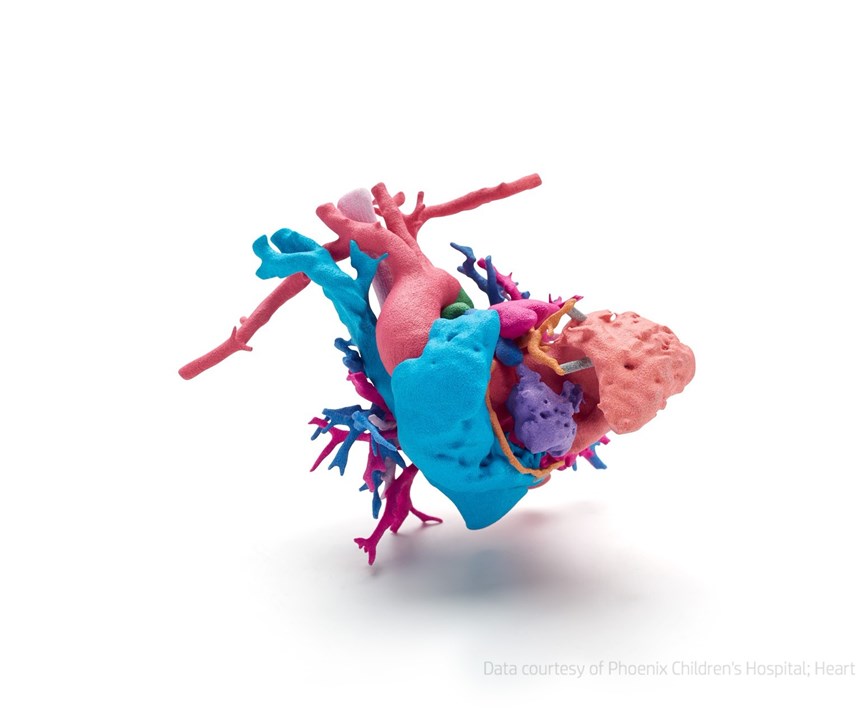

The new units have the same degree of precision as the production models (layer thickness of 0.08 mm/0.0031 in.), which means that they can build prototypes that represent exactly the properties of production parts. Two models in the 300/500 series also offer a brand-new capability—full-color printing (“millions of colors”) in addition to standard black or white. There’s a new grade of High Reusability nylon 12 powder tailored for the new printers that’s said to offer the same mechanical properties and surface finish as the grade used on the larger printers.

Related Content

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.