Automation: Compact Automatic Tool Changer For Collaborative Robots

It’s certified for use with UR cobots.

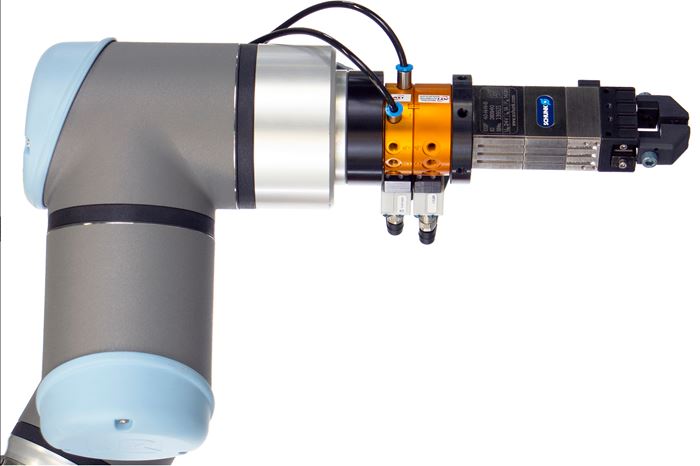

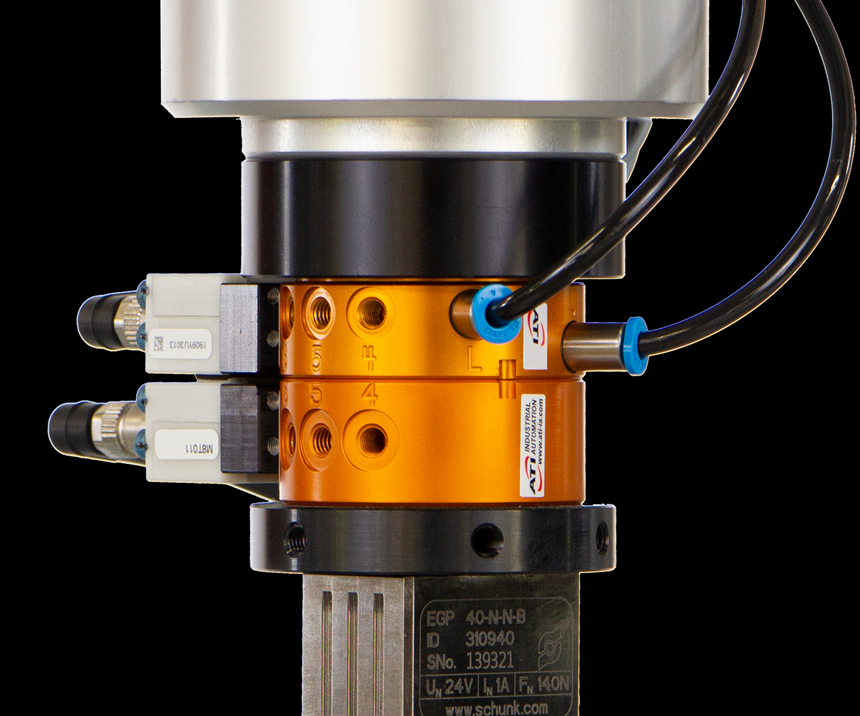

The QC-11 automatic tool changer for robots comes from ATI Industrial Automation and is now certified to work seamlessly with collaborative robots (cobots) from Universal Robots, joining more than 150 products in the UR+ portfolio that offer plug-and-play compatibility with UR cobots.

The QC-11 enables automatic exchange of robotic end-effectors without any manual intervention. Thus, the robot—or cobot—can utilize multiple end effectors in a single process. When coupled, the master and tool weigh less than 0. 55 lb, with a combined stack height of 2.06 in. The small footprint of the QC-11 helps optimize the robot/cobot payload and work envelope while supporting the maximum UR payload of 22 lb. The pneumatically actuated locking mechanism reportedly will not fail during a loss of air pressure.

Related Content

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

-

Why Are Cobots Popping Up in Injection Molding Processes?

Collaborative robots (cobots) can play a vital role in broadening a plastics processor’s automation portfolio.