Higher Productivity & Energy Savings for Packaging, Industrial Parts

NPE2024: Bekum is running EPET on its first U.S.-built all-electric shuttle. it is also highlighting the new XBLOW 200 industrial machine with new clamp design, plus a new extrusion head, three-layer retrofits, energy-saving extruder and EBLOW 08 electric shuttles.

Running EPET at Bekum’s booth is the company’s first U.S.-built all-electric shuttle, the 15-ton EBLOW 407D. Source: Bekum America

Among at least six new hardware introductions at the show, Bekum America is highlighting two machines in particular. One is the EBLOW 407D, its first U.S.-built all-electric shuttle. It incorporates mostly domestic components — including the patented C-frame E-Twin Toggle and the seven or more servo motors plus actuators — making availability of spare parts simpler and more reliable.

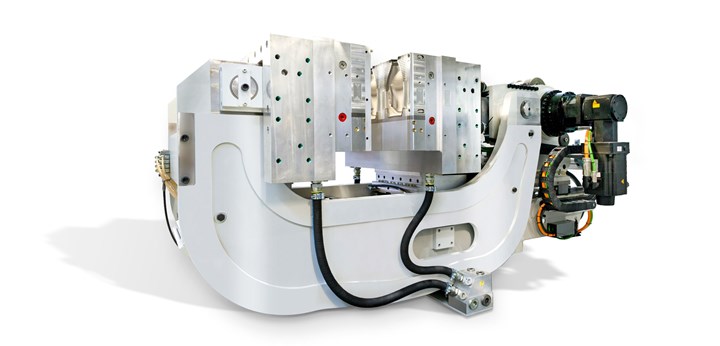

Bekum’s patented C-frame E-Twin Toggle clamp is designed for quick mold changes. On the EBLOW 407D, the clamp and all its servo motors and actuators (except the E-Twin Toggle) are U.S.-sourced. Source: Bekum America

This midsize, double-sided model is a “four-cavity gallon machine,” having a 15-metric-ton clamp, 520-mm stroke and 500-mm maximum mold width. It’s running (for the first time in public) EPET handleware (2 L, two cavities) to demonstrate that electric machines can handle such a tough application as hard-to-trim EPET.

Another highlight of Bekum’s booth is the brand-new XBLOW 200 industrial machine (200 m.t.), shown here with accumulator head. It can blow 500 L tanks in a single cavity. A key feature is the new clamp design with diagonal tie bars and fast movements due to two-stage action with servohydraulic or hybrid cylinders. (Source: Bekum America)

The second main highlight is a brand-new industrial machine, the XBLOW 200, for containers up to 1000 L. Though not physically present, a video of it in action and a 500-L tank produced on this 200-metric ton machine are on hand. The XBLOW series (announced at K 2022) features a new clamp design with two diagonal tie bars and rapid movements via a long-stroke toggle (servohydraulic or electric) paired with a servohydraulic short-stroke cylinder. This series can have accumulator or continuous extrusion heads.

A brand new continuous-extrusion head, model BKW400-3, is for producing drums and industrial containers up to 250 L on the XBLOW 100 machine. The new spiral-mandrel design is said to provide improved parison concentricity and layer uniformity in tri-layer coextrusion, as well as faster color changes. This head can be part of a three-layer retrofit package for upgrading monolayer machines (at lower cost than buying a whole new machine).

Available as part of the three-layer retrofit, or on monolayer machines, is a new extruder concept that’s already popular for industrial machines in Europe and is catching on here, says Bekum. The key is saving energy with a primary extruder of smaller diameter and longer L/D. For example, a 60-mm, 36:1 extruder is said to have the same length and output capacity as a 90-mm, 24:1 unit, while using 18-20% less energy.

Pictured at the booth is Bekum’s 08 series of all-electric shuttles, introduced at K 2022. These have spiral-mandrel heads and C-frame clamps in 6 to 50 metric tons; some have extra-long strokes greater than 1 meter. Designed for quick mold changes, they also introduced the new BC 8.0 controls — now standard on all new Bekum machines.

Related Content

-

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

.png;maxWidth=970;quality=90)