Last June, Pregis announced an $80 million investment in a new 168,500 ft2, state-of-the-art blown film extrusion facility in Anderson, S.C. Just six months later, the first rolls came off of one the high-tech Windmoeller & Hoelscher (W&H) multilayer lines in this pristine factory. And a mere four months after that, as Plastics Technology was paying a visit, the company was breaking ground on a plant expansion there.

Wow.

Meanwhile, last September, Pregis also announced it would spend $32 million to upgrade technology at its Grand Rapids, Mich., blown-film plant. The investment in Michigan added 55,000 ft2 for manufacturing, warehousing and offices, bringing the total plant size to 205,000 ft2. Pregis added an undisclosed number of custom W&H lines in this new space, with room to add more as needed. The investment came on top of the $46 million capital expenditure put into that location between 2016 and 2020.

The investment in the Michigan facility also included additional material-handling equipment for expanded resin storage. Further, Pregis upgraded the lab in Grand Rapids with new equipment for improved analytical capabilities. An on-site R&D team collaborates with customers to optimize film structures and blends for specific applications.

Wow.

The Michigan plant used to belong to Eagle Film Extruders, a processor of high-quality mono- and multilayer blown film used for a variety of packaging applications. Its purchase by Pregis in 2015 was driven by demand from Pregis’ own need for additional high-quality film, as well as external flexible-packaging opportunities. This was the first step in Pregis’ plan to expand its footprint in the very highest end of the flexible-packaging market. Before all this, the Chicago-based company was known primarily as a supplier of protective packaging films, where it is still a major player. Now, the South Carolina and Michigan facilities have been combined to form Pregis Performance Flexibles.

Pregis Performance Flexibles wound its first rolls at the new Anderson plant last December. Just a few months later, it is breaking ground on an expansion.Jon McClure, president of the Anderson operation, is second from left. Photo: Pregis

About the new plant in South Carolina, Pregis president and CEO Kevin Baudhuin notes, “We believe that this new facility is the most technologically advanced extrusion facility in North America. We have staffed it with technology and market leaders who are focused on developing extruded films that have been engineered to meet market-driven performance requirements.”

The newly minted Pregis Performance Flexibles will produce PE-based structures for a wide range of packaging applications that include food and beverage, consumer products, healthcare and industrial. For food and beverage, Pregis Performance Flexibles will be supplying films for snacks and confectionary, meats, fruits and vegetables, dairy, frozen and processed food, beverages and pet food. Consumer-product films target paper towels and tissue, personal hygiene and household goods. Targets for healthcare films include medical-device packaging and personal protective equipment. In industrial markets, Pregis Performance Flexibles furnishes film for wrapping and bundling, protective masking, and building and construction.

“The strength of Pregis helped get us up and running a lot faster than would have been possible otherwise.”

Pregis Performance Flexibles has organized its offerings into four series. It has designed the Renew sustainability series to accommodate the requirements of a circular economy by utilizing less material overall and more recycled content, and engineering film blends that are pre-qualified for How2Recycle store drop-off. Its High-Performance series is engineered for physical toughness, has a modulus-forward design, meets water-vapor transmission and other critical performance specs, and can be formulation-customized. The Barrier series is built for oxygen, moisture, odor and chemical requirements; leverages High-Performance series toughness protection, and also can be formulation-customized. The General Performance series is billed as highly versatile, high-quality and suited for diverse applications.

Pregis engineers all films in what it calls a “performance-first” approach to developing lightweight film solutions that adhere to Association of Plastic Recyclers compliance standards and can incorporate recycled content.

Inside Anderson

Baudhuin likes to say Pregis is in the “wow” business, a claim that would be hard to dispute after viewing the new plant. And Pregis has brought on board some of the packaging industry’s most well-known and established experts to lead its flexible film operations. Earlier this year it named Jon T. McClure president of its Anderson operation. In 1997, McClure founded South Carolina-based ISO Poly Films Inc. and served as the company’s CEO until it was sold in 2014. Under his leadership, ISO Poly became a leader in custom film production with two state-of-the-art manufacturing facilities and 160 employees, generating $115 million in sales.

Dave Timm (l.) and Jon McClure joined forces in 2021 after being friendly competitors for years at other film processors. (Photo: Grilliot Photography)

Dave Timm (l.) and Jon McClure joined forces in 2021 after being friendly competitors for years at other film processors. (Photo: Grilliot Photography)

Last June, Pregis named Dave Timm president of the overall flexible films business. Before this, Timm was president and COO of Charter NEX Films, a blown film company he founded and managed for more than 20 years. Before that he served in technical roles for Atlantis Plastics and Printpack.

There’s an old adage, “If you’re going to go, go big.” Pregis, by virtue of its investment in bricks and mortar, equipment, and talent, went big. McClure and Timm—friendly competitors at their most recent places of employment—gave some consideration to starting their own film processing operation but opted to partner with Pregis to get things going more quickly. Comments McClure, “The strength of Pregis helped get us up and running a lot faster than would have been possible otherwise. Getting a state-of-the-art facility like this one up and producing film in less than one year would have been very hard to do.”

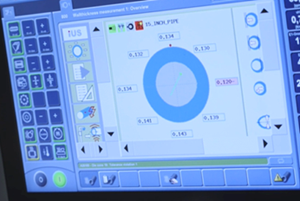

Of the 168,500-ft2 footprint in Anderson, some 50,000 ft2 is devoted to manufacturing. Pregis Performance Flexibles currently runs an undisclosed number of W&H Varex 2 lines there, with room for more. Lines have capacities for up to seven layers and are equipped with W&H’s latest bells and whistles, including its TurboStart and TurboClean technologies and its Ruby control platform. TurboStart is an automatic line shutdown and startup system that W&H launched at K 2019. TurboStart guides the operator through a simple process—all on one screen—that reduces the more than 500 manual parameter changes to a seven-step sequence that is said to cut startup and shutdown times by more than 50%.

Pregis’ W&H Varex 2 blown film lines feature all of the machine builder’s latest enhancements, including control systems to facilitate startups, shutdowns and changeovers. (Photo: Grilliot Photography)

TurboClean, meantime, is W&H’s quick-product-change system that was launched at K 2016. Ruby is the machine builder’s Industry 4.0 control system that allows users to monitor data, automate and improve production. The lines, of course, are all designed for high output. As Timm notes, “The vision is to compete at high volumes to serve our target markets. But custom packaging is not just about output, as we are not making the same products every day.” Timm estimates the combined capacities of the Grand Rapids and Anderson plants at 100 million lb/yr.

“Our continued investment in state-of-the-art assets demonstrates our commitment to stay ahead of shifting market demands.”

Lines at Anderson are fed material from eight outdoor silos. Additives are stored in vessels off the production floor and fed to lines as needed. To maximize formulation flexibility, each line can accommodate up to 35 different materials. There are no boxes or gaylords on the production floor. The blown film mezzanine is not the typical steel structure, but is made of cement and 80-ft high, custom built to McClure’s specifications. This helps keep the production floor cool, which is extraordinary when multiple blown film lines are running.

The current plant in Anderson has room for two more full production lines, which McClure has ordered. The blown film systems are set back from the entrance to the plant by about 50 ft. Timm says this provides enough space should the company decide to employ automatic guided vehicles to bring rolls from the production floor to an adjacent warehouse. “Our continued investment in state-of-the-art assets demonstrates our commitment to stay ahead of shifting market demands,” Timm says.

Pregis Performance Flexibles has also equipped the plant with an NGR reclaim line for pelletizing any off-spec product. Pellets from this post-industrial scrap are then refed to the film process. The plant is also furnished with state-of-the-art testing and validation and development labs.

The Anderson facility features the latest in energy-efficient manufacturing and other plant functions. Pregis’ commitment to sustainability is outlined in its 2K30 environmental goals: to run its businesses in the most sustainable way possible so that the company improves its carbon footprint and reduces environmental impact while making significant, positive contributions to people and society.

Pregis Performance Flexibles in Anderson, S.C., has a central storage and conveying system just for additives. (Photo: Grilliot Photography)

As a result, the plant in Anderson complies with LEED (Leadership in Energy and Environmental Design) standards for all appropriate materials. Building materials were specifically selected to cut down on the environmental impact of maintenance and upkeep. The plant was built with water- and power-conserving measures; there are ample skylights and bright reflective paint to reduce dependence on artificial light sources. No single-use water bottles are provided at the plant.

The facility is furnished with energy-efficient lighting and equipment, automated HVAC and auto-shutdowns for electronics, and other conservation best practices. A waste-recovery system is engineered to achieve the goal of making Anderson a zero-waste facility. Recycled materials are used throughout the facility, including for building materials and office furniture. Products are shipped without pallets and scheduled to optimize payloads, contributing to Pregis’ goal of creating transportation efficiencies that reduce greenhouse gas emissions.

Comments McClure, “Our vision is to be a nimble competitor of high-quality, high-tech films produced from a plant that has the lowest carbon footprint in the industry.”

McClure and Timm also promise Pregis Performance Flexibles will “revolutionize” the customer experience. Customers will have their own portal to offer instant access to account details and real-time tracking of order progress. It has also devised a new approach to product numbering—a more intuitive product name and number structure that will reportedly make ordering and re-ordering quick and simple.

All this, in less than one year. And an ongoing expansion in Anderson that will add another 150,000 ft2 to the campus.

Wow.

Related Content

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Read MoreFully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreRead Next

Film Processor Pregis Invests $17 million in Expansion

Firm announces name change to Pregis Films in light of 2015 acquisition

Read MorePregis Begins Production at New S.C. Plant

$80 million investment in blown-film plant will create 120 new jobs.

Read MorePregis to Invest $32 Million at Michigan Blown Film Site

Processor responding to increased demand for high-quality films.

Read More