Biobased Additives Compatible with Range of Commodity Resins

UBQ Materials has added sustainable additives compatible with a all commodity thermoplastics and PLA.

Israel’s UBQ Materials has expanded its globally patented waste-to-materials technology with the addition of sustainable biobased additives. The company confirms that the new additive formulations are compatible with PP, HDPE, LLDPE, PS, PVC and PLA and can replace various percentages depending on the application. Says a company source, “For example, if a pallet is made with PP, one of the new formulations would partially replace and be compatible with it, without compromising quality and durability.” As previously reported, UBQ’ advanced waste conversion technology creates a biobased thermoplastic composite by breaking down to their basic particulate constructs unsorted municipal solid waste including organics such as garden trimmings, soiled cardboard, and food waste and reassembled into a matrix.

Also based on UBQ’ technology, the new material replacements and additives are formulated to resolve performance challenges commonly encountered when integrating sustainable materials. The product lines are suitable as sustainability additives (10% to 30% load of UBQ-based material), or as material replacements (greater than 25% and higher load of UBQ-based material). This enables compounders and manufacturers to determine the right load level to balance consistent functionality with sustainability benefits. The portfolio includes three biobased sustainability additives and material replacement—ClimaPos, Q Series and Industrial, each tailored for different sustainability needs, encompassing circularity, recyclability, low-carbon footprint, and climate-positivity:

▪ UBQ ClimaPos: A biobased, climate-positive sustainability additive that enables greenhouse gas removal and avoidance and assists companies in achieving or surpassing ambitious climate objectives. With proven uses including planters, pet carriers, transport boxes, and window profiles, incorporating as little as 5%, ClimaPos can shift a product's carbon footprint to carbon neutrality.

▪ UBQ Q Series: The proven, standard material replacement known as UBQ, the Q Series is a one-to-one material swap that blends with most polymers. It can be used across industries, including automotive and mobility, building and construction, and logistics and supply chain management applications and is suitable for use on its own where final product characteristics permit.

▪ UBQ Industrial: A material replacement engineered for high-value function and reliability in operational uses, from shipping pallets in logistics to bitumen roofing or building infrastructure, UBQ Industrial is a cost-effective material choice when appearance matters less than functionality.

These primary formulations can be combined with additional modifiers or enhancers to achieve desired properties, optimizing product development, and reducing guesswork for product manufacturing. Supporting formulations for additional benefits include:

▪ UBQ Nclozur: A sustainability modifier formulated for odor mitigation, UBQ Nclozur is ideal for indoor and interior applications, which can include automotive interiors, consumer products, flooring, footwear and carpet backing.

▪ UBQ Impact: An enhancer that blends with a range of polymer matrices to meet performance requirements, enabling business to bring climate-positive circularity to applications as diverse as decking, office furniture, and car-door mirrors.

By incorporating as little as 5% of a UBQ material replacement or additive, businesses can – whether in a single product application or across its supply chain – achieve greater circularity, carbon-neutrality or even carbon-negative/climate-positive status. By designing products with various load levels and capabilities, UBQ enables businesses to achieve productivity goals while transitioning away from fossil-based plastics. UBQ will work with its compounding partners, value chain manufacturers, brand partners and product development teams to tailor the ideal formulation for each specific application.

Related Content

50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

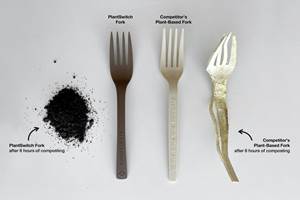

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreWhy Are They Blending Biopolymers?

A sit-down with bioplastic producer Danimer Scientific showed me there are more possible answers to that question than I had previously thought.

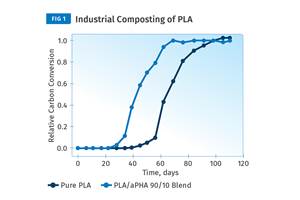

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More