Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

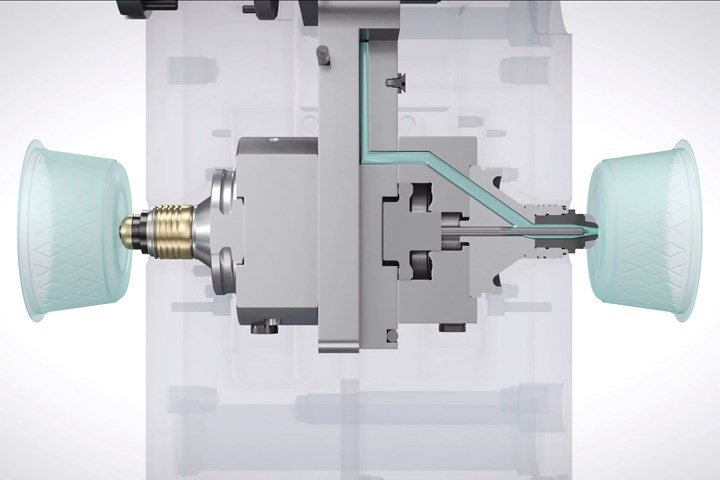

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin wall packaging applications. Designed to withstand high filling pressures for thin wall packaging applications, the system, which will be available soon, can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

The design fits a maximum hot half plate thickness of 220 mm with a minimum distance between the gates on either side of the plate of 260 mm. In a video released with the announcement, Oerlikon HRSflow showed a four-drop design molding two 210-ml single-serving cups in recycled PP with a weight of 6.3g and a wall thickness of 0.3 mm on either side of the middle plate. What Oerlikon HRSflow calls a “mosaic” design on the cups’ walls was patented by moldmaker Collomb and imparts robustness to the container despite the thin walls.

The center plate of Oerlikon HRSflow’s stack mold fits a maximum hot-half plate thickness of 220 mm.

Photo Credit: Oerlikon HRSflow

Related Content

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

.png;maxWidth=300;quality=90)