Microcellular Foaming Paired With Specialized Screw, Process Control Program

KraussMaffei will apply its APCplus dynamic process control technology and an optimized screw with the MuCell process in Friedrichshafen.

At Fakuma KraussMaffei will demonstrate MuCell on an all-electric PX 321-1400, featuring an optimized HPS-Physical Foaming (HPS-PF) screw and the first use of its APCplus program with microcellular foaming.

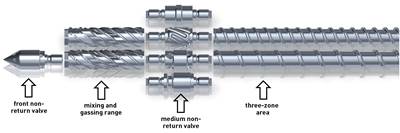

The company says it created the new HPS-Physical Foaming screw with a longer three-zone area, specifically for MuCell. KraussMaffei says the screw works for all plastics — with and without fiber reinforcement — and it provides up to 30% more plasticizing capacity. This enables molders to select smaller screw diameters than before, reducing investment and operating costs for the plasticizing unit, while generating greater output.

The PX 321-1400 MuCell with new universal screw with up to 30% more plasticizing capacity. Photo Credit: KraussMaffei

KraussMaffei tested variants of existing MuCell screw designs, including front and center check valves, and single-flight and double-flight three-zone areas, using a modular system. As mentioned, the APCplus machine function is being used with a gas-charged melt for the first time. APCplus shifts the changeover point and the holding pressure profile of the molding process from shot to shot based on the measured melt viscosity.

To demonstrate the technology package, KraussMaffei will create a storage table for trucks and commercial vehicles. Project partners include Isosport (Eisenstadt, Austria), which provided surface decoration via in-mold labeling. Specifically, the decorative film was required to prevent bubble formation from the outgassing nitrogen.

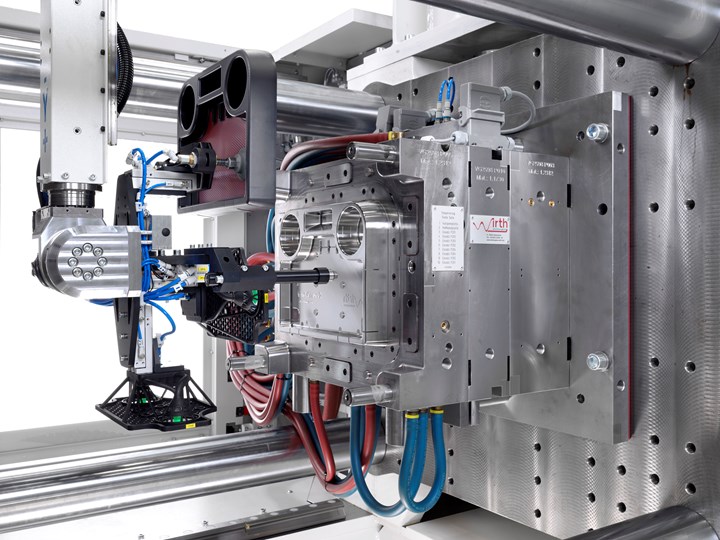

The LRX 150 linear robot removes finished parts from the mold. Photo Credit: KraussMaffei

Wirth Werkzeugbau (Helmbrechts, Germany) provided the tool, which required precise cooling to prevent what is known to the MuCell process as the post-blow effect, wherein bubbles emerge on the surfaces after molding. Specifically, special mold cooling channels were used to ensure uniform cooling at the surface, without variothermal technology, and safely prevent hot spots.

Surface effects were aided by graining technology from Reichle (Bissingen/Teck, Germany), with Lyondellbasel supplying resin. Jurke Engineering provided its Orca tempature control unit for the cell, measuring the speed and volume of coolant flow ultrasonically.

Trexel supplied the MuCell technology, continuing a collaboration with KraussMaffei that goes back to 2001. The metering system, which is fully integrated into the KM MC6 machine control, supplies the necessary gas using only one compressor.

For the process, an LRX 150 linear robot from KraussMaffei picks up the blank film from a drawer in which four different film types are stored. The robot then places the selected film on the cleaning station, where all particles and/or contaminants are removed using a cleaning brush from Wandres (Stegen, Germany) and the matching extractor system from ESTA (Senden, Germany). The robot gripper then uses clean suction cups to pick up the cleansed film.

From there, the stack gripper inserts the film into the mold and the finished part is demolded, with a “handshake” transfer to a second robot for a foam structure test using a system from Teratonics (Orsay, France). The testing system specifically enables users to visualize the compact outer layers and the spatial distribution of the MuCell foam in the interior of the component and to assess the production as free of bubbles.

All the while, the easyTrace 2.0 systems collects all process-related data, as well as the structural test for each part. A QR code that stores all process parameters for this individualized component is then created.

At Fakuma, the PX 321-1400 molds a storage table for trucks in four different designs utilizing MuCell. Photo Credit: KraussMaffei

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreRead Next

Modular Screw Optimized for Microcellular Foam Molding

KraussMaffei says its HPS-Physical Foaming screw features a universal design and 30% higher plasticizing capacity for MuCell molding.

Read MoreTrexel Forming Global Network For MuCell Engineering Support

Taking a more direct role in part, tool, and process design for specific applications.

Read MoreKraussMaffei Invests in Future Plastics Professionals

KM is doing its part through machinery donations, as well as co-op and apprentice programs.

Read More