Fakuma: Compact Hot Runner With Low Space Requirements

Oerlikon HRSflow will bring the S Series to Friedrichshafen targeting small-format technical components.

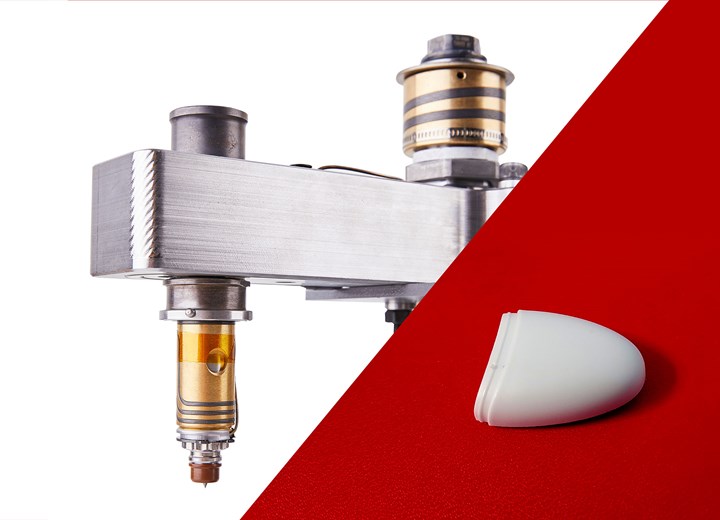

Oerlikon HRSflow will display the S series of small hot runner systems at Fakuma 2021 (Oct. 12-16; Friedrichshafen, Germany) in Hall A2, Stand 2217. Targeting small-format technical components, the new S series can be equipped with screwed-in or non-screwed-in (face-to-face) nozzles, and the inner bore size can be selected according to shot weight. The design allows a compact mold structure with a minimum nozzle pitch of 37 mm. In the valve-gate version, the S series is combined with either a compact cylinder that is 62-mm high or, in the version with adjustable needle position, 70-mm high. Oerlikon HRSflow says extensive internal laboratory tests have proven out optimal sealing and a consistent thermal profile along the whole nozzle. In addition, the company notes that a special channel geometry enables fast color changes.

Oerlikon HRSflow says the S series works with low shot weights, multi-cavity molds and thin-walled components. Typical applications include consumer goods, technical and electronic components, as well as small automotive parts such as emblems, interior switches and knobs.

At Fakuma, Oerlikon HRSflow will use the S series to mold a Hydration Reminder from polypropylene (PP). Attached to bottles or glasses, it reminds the user by signal to drink regularly. The S series made it possible to meet the requirements for a low part weight with a wall thickness of only 1 mm, while also enabling fast color changes.

Typical applications of Oerlikon HRSflow’s new S series hot runner line include small technical parts such as the housing for a smart device called Hydration Reminder.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

.png;maxWidth=970;quality=90)