Granulation Gets Connected at K 2022

Rapid Granulator offers innovations in energy efficiency, serviceability, and connectivity.

With K 2022 just around the corner (October 19), Rapid Granulator has announced the innovations it will be highlighting including equipment and system monitoring for shredding and granulation.

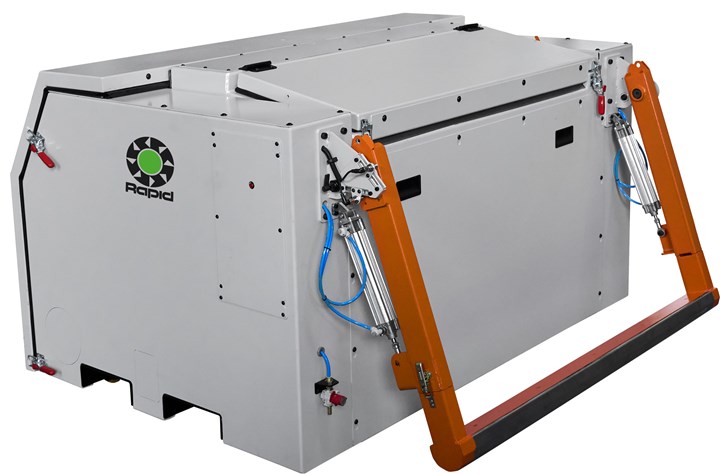

Rapid GT Series

The new GT series is for in-line processing of skeletal waste from sheet and film thermoforming lines. The series is designed for maximum uptime and easy operator access. The entire chamber slides out for complete access from one side for easy cleaning and service. The GT1100, capable of granulating webs up to 43 in. wide, will be on display at K.

The Rapid GT11000 granulator for thermoforming lines.

Photo Credit: Rapid Granulator

Raptor Duo

The Raptor Duo is a one-step shredder and granulator. It too is designed for easy maintenance, featuring an open-hearted design that provides direct access to the cutting chamber. 36 base configurations of the Raptor Duo will be offered, to handle a wide variety of applications. The modular systems come in two widths (31.5 and 53 in.) and three different cutting systems.

Raptor Duo one-step shredder.

Photo Credit: Rapid Granulator

Rapid Connect Transmitters.

Photo Credit: Rapid Granulator

Rapid Connect

Rapid Granulator will also present its Rapid Connect product. Rapid Connect is designed for live-feed monitoring and reporting. The system provides recycling machine data to enterprise resource planning software, sending prompt notifications of equipment problems and enabling data analysis of uptime and energy use. Rapid Connect can be installed on any recycling equipment, it does not need to be a rapid brand machine. Multiple machines can be connected to the system to provide an overview of an entire production setup.

Related Content

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

-

Calculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

-

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

.png;maxWidth=300;quality=90)