Hot Runner Temperature and Mold Motion Controllers Debut

NPE2024: Hot runner systems, temperature and motion controllers, an auxiliary injection unit and a gate seal are among Mold-Masters’ show plans.

All new for hot runner supplier Mold-Masters at NPE2024 are the TempMaster M4 hot runner temperature controller and the M-Ax mold motion controller. The TempMaster M4 features Mold-Masters’ new HR-Connect technology, which replaces conventional mold thermocouple and power cables with a single lightweight cable connecting the mold to the control head unit. The TempMaster M4 also features the Mold Direct Mount design. A Mold-Masters spokesperson told Plastics Technology that the predecessor M3 control utilized TC-Connect technology, which eliminated just the conventional thermocouple cables. The new HR-Connect eliminates conventional thermocouple and power cables.

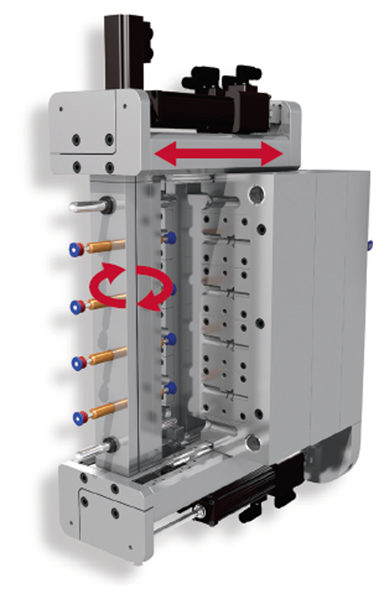

The next-generation M-Ax mold motion controller features a simplified user interface with special features, including preprogrammed mode functions as well as energy and torque monitoring. Energy monitoring enables molders to measure and track the energy consumption of their motion controls, while torque monitoring can be used for a variety of purposes as determined by the user. M-Ax can control a variety of functions, including valve gates, core pulls, rotary tables and spin stacks, as well as coining, index, stripper and ejector plates. Supporting rotary or linear movements, the control has up to 64 programmable inputs and outputs.

M-Ax mold motion controller. Source: Mold-Masters

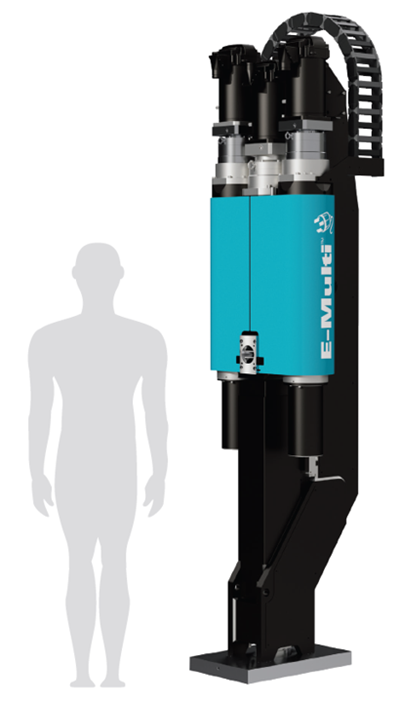

Additional products featured at the show will include the company’s E-Multi product line of auxiliary injection units, which now includes the E-Multi mini. A compact, lightweight unit designed for small shot weights, the E-Multi mini is affixed to the mold and can be mounted in nearly any orientation, with a pivoting hopper to accommodate challenging installation positions. The E-Multi is available in shot ranges from 0.26 to 42 oz., and can run a range of materials, from PCR and bioresin to LSR.

The Sprint APEX gate seal minimizes flow lines, improving environmental stress crack resistance (ESCR) of carbonated soft drink caps to support lightweighting. It is also designed to enhance part quality, improve color change and minimize maintenance costs by eliminating the insulation cap associated with standard gate-seal designs. Sprint Apex is premium gate seal option available for the Sprint hot runner system, which is optimized for caps and closures.

Hot Runners, Co-Injection

Mold-Masters NPE2024 exhibit will include U.S. debuts for the Fusion Series G3, which was featured at K 2022, and the EcoONE-Series, introduced earlier this year. The Fusion Series G3 hot runner system comes preassembled and features compound nozzles; a heated nozzle flange; quick-change headless valve pins and waterless actuators featuring passive actuator cooling technology.

The EcoONE-Series of hot runners, with one to eight drops, is described as an economical, standardized solution for processing commodity resins into simple, cost-sensitive applications such as consumer goods, small home appliances and basic automotive components. The line is offered with an assortment of standard components, including nozzles, and a shot range capacity of <5 g up to 3,500 g and lengths ranging from 50 to 300 mm, with custom pitch-range manifolds.

Mold-Masters’ co-injection multilayer system will mold 5-gallon pails with recycled cores on a 950-ton machine at the show. Maximizing the use of recycled content, the technology enables molders to incorporate recycled content up to 50% of total part weight as the core layer between two layers of virgin resin.

Related Content

Six Years in the Waiting, PLASTICS Igniting a ‘Spark’ at NPE

New features of NPE2024 aim to “bring the whole plastics ecosystem together to innovate, collaborate and share findings.”

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreInfrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

Read MoreRead Next

K 2022: New and Established Hot Runner, Mold and Injection Technology

Mold-Masters will showcase numerous hot runner systems, controllers and auxiliary injection units at K 2022.

Read MoreHot Runner System for Commodity Resins

Mold-Masters’ EcoONE series hot runner system is optimized for processing commodity resins for simple, cost-sensitive applications.

Read MoreLarger Capacity Auxiliary Injection Unit Introduced

Mold-Masters has extended the capabilities of its E-Multi auxiliary injection platform, introducing the new larger capacity EM5 model.

Read More.png;maxWidth=970;quality=90)