K 2022: New and Established Hot Runner, Mold and Injection Technology

Mold-Masters will showcase numerous hot runner systems, controllers and auxiliary injection units at K 2022.

At K 2022, Mold-Masters will launch its new Fusion Series G3 hot runner system. Shipped completely pre-assembled, pre-wired, plumbed and tested for fast one-step installation, the Fusion G3 provides several major enhancements over the previous iteration, which are intended to optimize mold design and simplify installation.

These include reduced nozzle bore cut-outs, new optional nozzle heater sleeves, more compact pneumatic and hydraulic actuators, and the possibility for room temperature installation. The more compact nozzle bore cut-outs help minimize tooling requirements and are available in customizable lengths up to 1000 mm (40 in). The nozzles use field replaceable heater bands and gate seals, and since most gate seals are interchangeable between G2 and G3, customers can convert to the new system without special retooling in many cases. Mold-Masters notes that the new heater sleeves protect the nozzle and wiring from damage during installation without impacting cut-out dimensions.

The new compact actuators minimize stack heights with cut-outs that are the same or smaller than those of the G2, and anti-rotation and valve pin disconnects are now standard. The position of air/hydraulic lines and cooling lines can be rotated to be set perpendicular or oriented differently to one another to allow easier access when space is limited. The Headless Valve Pin is a new feature that can be re-worked in the field with steel-safe dimensions. Designed to be installed and uninstalled at room temperature, the Fusion G3 can be pulled directly from the box and placed into the mold. The system can be covered with a 5-year warranty.

Mold-Masters has also optimized its Axiom Thermal Gate (TG) single-stage PET hot runner system, including a new optimized nozzle and gate seal design that incorporates the company’s iFLOW manifold technology. The new Axiom TG nozzle reportedly features a strong thermal profile for precise and repeatable processing. The nozzles incorporate individual heaters for distinct temperature control. These are field replaceable for easy maintenance, and they incorporate a threaded nozzle base for integrated leakage protection. The gate seal design closes on the face and incorporates an industry standard cut-out, allowing for direct replacement for many common single-stage hot runner systems.

Also on PET Mold-Masters will feature its PET-Series hot runner system, which enables thinner preforms in support of light weighting. Reportedly with better balance and less variation in preform weight, PET Series can provide a cycle-time reduction due to faster fill time, while allowing a wider process window and reduced acetaldehyde (AA) content. Here as well, iFLOW manifold technology is utilized, with a two-piece manifold designs that incorporates patented melt flow geometry.

Mold-Masters PET Series feature an improved thermal profile.

Photo Credit: Mold-Masters

In addition, Mold-Masters is also introducing a new PET-Series nozzle with improved thermal profile, a field replaceable heater sleeve and industry standard gate design. PET-Series nozzles also incorporate new MasterSHIELD Technology for enhanced leakage protection between the nozzle and manifold, even during cold start-up.

Mold-Masters will also introduce the Cylindrical Hot Valve – CP (CHV-CP) Gate. This new gate seal is engineered to extend gate quality production life and simplify maintenance. Suitable for packaging and other similar applications it is compatible with PP, PE, TPE and other commodity resins. Featuring enhanced pin guidance, the technology funnels the pin to the gate to avoid contacting cavity steel, which serves to minimize wear, maintain gate quality and extend service life.

These also feature a replaceable gate insert, giving molders with an easy-to-replace component. This eliminates traditional gate hole rework and welding, while making maintenance costs more predictable and minimizing downtime. The compact Ø3mm outer diameter tip, with a 1.0-mm gate, can fit on a wide range of parts and produces a double witness ring. Mold-Masters notes that since tip contouring and texturing are possible the ring’s visual impact on the part surface can be minimized.

On the liquid silicone rubber (LSR) molding front, Mold-Masters is highlighting a partnership with LSR toolmaker Kipe Molds (Placentia, Calif.) on a valve-gated cold deck. Mold-Masters LSR cold decks feature specialized LSR nozzles for a wide range of shots and include optimized gate designs, promoting faster cycle times and higher part quality. Integrated water jackets accurately maintain process temperatures to help ensure part quality. The valve-gated designs enhance process control and allow for a range of material viscosity compatibility.

In addition to its LSR Cold Deck, Mold-Masters also offers the E-Multi LSR auxiliary injection unit, giving any machine the capability for a second shot of LSR for over molding.

The company will also highlight its Dura+ hot runner system for automotive lenses. Available with a 10-year warranty, the hot runner is constructed corrosion resistant materials, extending its service life and helping prevent contamination defects. Dura+ hot runners incorporate field replaceable components, including nozzle heater sleeves, manifold flexible tubular heaters and manifold heater plates.

Saying they target demanding medical, personal care and technical molding applications, Mold-Masters will also showcase the Summit Series of hot runner nozzles, which it says can run abrasive, corrosive and shear- and temperature-sensitive resins like PC, POM and PBT. The Summit Series nozzles feature a precise thermal profile, with reportedly only 5% maximum temperature variation. Constructed with special materials and coatings, the nozzles offer improved durability and extended service life. Summit-Series also features Mold-Masters’ iFLOW manifold technology with patented melt-flow geometry, flow-path options and runner shapes. Here too, a 10-year warranty is available.

Also at the show, the TempMaster-ME hot runner temperature controller launched in 2021. Mold-Masters says the ME platform represents an economical and simple to operate and maintain, controller. Suitable for low-cavitation molds, with a maximum of 12 zones, the controller’s features include Soft Start, Wet Heater Bakeout, Continuous Ground Fault Detection, Overload Protection, Automatic Tool Diagnostics, Plastic Leak Detection, Tool Storage and more. Supply voltage is 200/240v 3P Delta or 380/440v 3P Star (480v, 3P with transformer). Since the TM-ME is a standardized off-the-shelf unit, inventory will be held at various global facilities for lead times of 24 to 48 hours.

For processing post-consumer recycled (PCR) materials, Mold-Masters will highlight its co-injection multi-layer technology, with applications containing up to 50% PCR. Mold-Masters’ largest capacity E-Multi auxiliary injection unit, the EM5, will also be displayed. The E-Multi is an all-electric auxiliary injection unit that extends the line’s capabilities with a shot range of 550 to 1237g (18 to 42 oz).

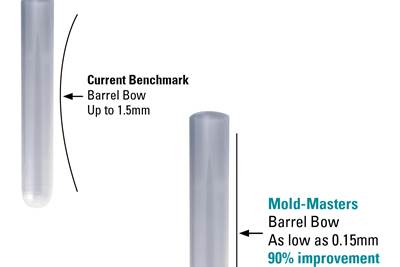

SYMFILL Technology, which can significantly minimize core shift and improve part quality and straightness of cylindrical, center-injected components with an aggressive L/D ratio, will be featured at the fair, as will the TempMaster M3 controller platform with enhanced plastic leak detection. Molders looking to bring Industry 4.0 to their tooling can also check the SmartMOLD cloud-based software platform for real-time data. Process data is collected by sensors embedded within the injection mold.

Related Content

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

Read MoreEnergy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.

Read MoreK 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

Read MoreRead Next

Molding Straighter Medical Tubes: New Hot-Runner Technology Battles Core Shift

A curvature or bowing effect in thin-wall PET blood tubes had long been accepted as the norm for the high-volume application, despite its impact on cycle time and downstream post-molding operations.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)