New HDPE Grade for Mono-Material Machine Direction Oriented Films

Exxon introduced HD7165L for MDO film applications designed for recyclability.

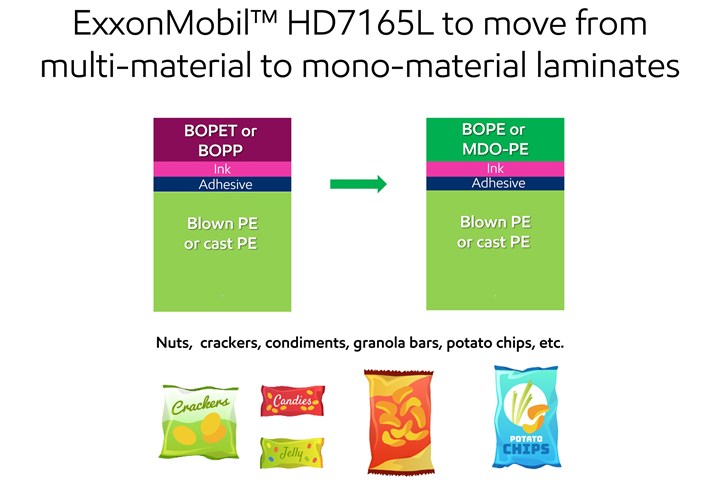

ExxonMobil announced it has developed a new high density polyethylene (HDPE) grade for machine direction orientation film (MDO) applications. Designed for recyclability (contingent upon availability of film collection programs), HD7165L can help converters create mono-material laminates to replace multi-material laminate structures, such as food packaging.

ExxonMobil’s new grade of HDPE is formulated to support transition to mono-material packaging for easier recycling.

Photo Credit: ExxonMobil

HD7165L can help enable converters to produce blown MDO-PE films with 60-70 percent HDPE for enhanced stiffness and high heat resistance when compared with films with a lower percentage of HDPE incorporated. Output rates in excess of 400 kg/hr are possible, while bubble stability is maintained.

MDO stretch ratios as high as 7:1, with very high stiffness (1% secant modulus as high as 200 ksi) can be achieved. HD7165L offers optical haze less than 10% and gloss higher than 60%. Where used as a print web of a PE-PE laminate, HD7165L offers high heat resistance, stiffness, and printability.

In blown MDO-PE film applications, HD7165L offers uniform orientation, gauge stability, and low gels for easy processability. Compared to a market reference HDPE grade, HD7165L delivers better shear thinning behavior and extrudability, higher melt strength for bubble stability, and gauge uniformity.

Related Content

-

The Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

-

Fundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

-

Prices of PE, PP, PS, PVC Drop

Generally, a bottoming-out appears to be the projected pricing trajectory.