New Hot Runner Cooling Design Lowers Energy Consumption, Maintenance

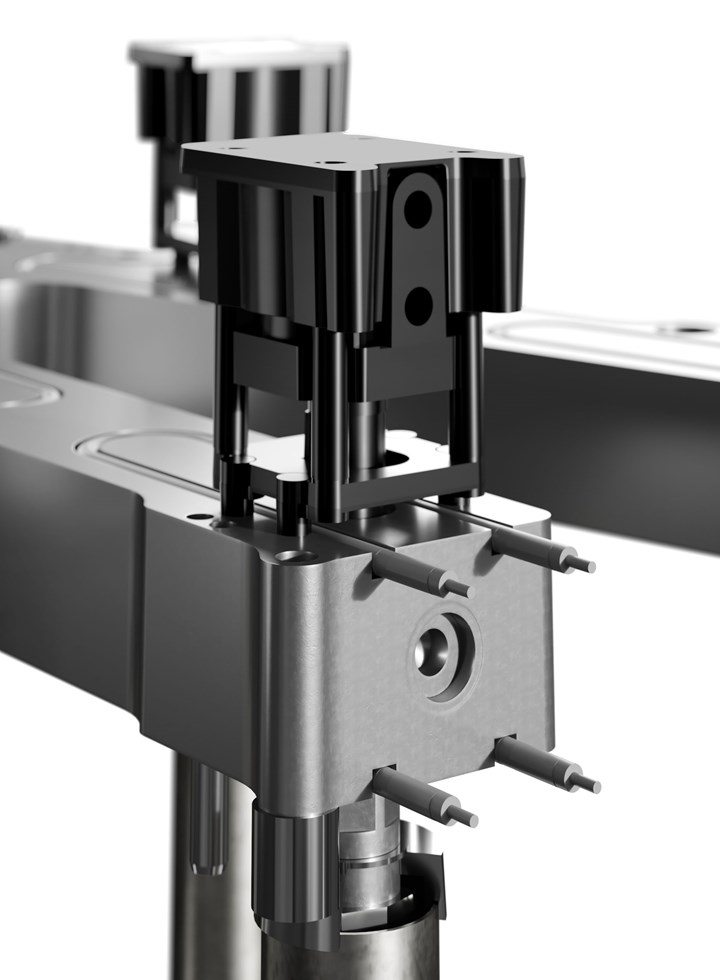

Oerlikon says the HRScool Evo’s design eliminates separate, active water cooling for the hot runner pin’s hydraulic cylinder, reducing energy consumption by up to 10%.

Hot runner supplier Oerlikon HRSflow has developed a system in which the hydraulic cylinder that positions the pin does not require separate, active water cooling. Depending on the system size and application, the company says its HRScool Evo technology can reduce energy consumption at the drops by up to 10%. In addition, eliminating active water cooling reduces the total number of components for the hot runner, which cuts the assembly and maintenance time.

Hot runner system cylinders act as high-precision actuators, and typically utilize water cooling to ensure the optimum working temperature is maintained. With HRScool Evo, a thermally insulating air gap towards the cavity is used to reduce both the heating of the cylinder and the thermal loss of the manifold.

In addition, use of a highly heat-conductive cover on the opposite side ensures optimum heat dissipation towards the cold clamping platen. The company notes that the height can be adjusted via telescopic supports, enabling molders to tune heat transfer and thermal uniformity over the entire hot runner system to maximize part quality.

Massimo Rossi, R&D Director at Oerlikon HRSflow, stated in a release that in addition to energy efficiency, the the elimination of lines and connections required for water cooling means these components can no longer become clogged or corrode. In addition, the ability to remove the actuators while the needles remain in the hot runner system further reduces maintenance, and limiting the design to a thermally insulating and thermally conductive element allows for a more compact design, with small cut-outs in the clamping plate sufficient for installation.

HRScool Evo replaces active water cooling with an air gap and insulating and conducting surfaces to improve hot runner actuator pin efficiency.

Photo Credit: Oerlikon HRSflow

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

.png;maxWidth=300;quality=90)