Patented Additive for Nano-Degradation of Broad Range of Thermoplastics Used in Packaging

Timeplast can mimic the natural enzymatic process up to 100% through a thermo-chemical and synthetically-based approach.

We were recently contacted by Material Connexion, a Sandow Media company, which boasts a 20-year run as a global materials and innovation resource that connects clients with over 10,000 materials and technologies to help create the products and services of tomorrow.

An expert team of material scientists works across industries to find the most sustainable and innovative materials that are setting industry trends, according to marketing manager Lynette Grodskiy. With locations in New York City, High Point, N.C., Bangkok, Bilbao, Daegu, Milan, Skövde, and Tokyo, Material Connexion's network of specialists provides a global, cross-industry perspective on materials, design, new product development, sustainability, and innovation.

“As experts in sustainability and innovation, we’d like to offer our material scientists’ best biodegradable discoveries that are benefiting our planet. One of the processes we recently added to our library, thanks to our material scientist Kerrie Masone, is Timeplast, the first green plastic solution,” Grodskiy said. The company claims Timeplast is the first and only patented additive for the nano-degradation of plastic. It reportedly can mimic the natural enzymatic process up to 100% by using a thermo-chemical and synthetically-based approach. “The end result is a powerful liquid that can turn almost any plastic into a wax. This liquid is used to remove 98% of the actual plastic while maintaining all of the same properties as the original plastic; however, it is more recyclable and it breaks down into wax instead of microplastics at the end of its lifecycle. While regular plastic does eventually degrade over time, this process takes thousands of years. TimePlast decreases the lifespan of conventional plastic from 1,500 years to around 15 years.”

We asked Grodskiy to provide some further clarification on the company and the additive as well as the status of commercialization:

▪ The manufacturer is TimePlast, located in Coral Gables, Florida.

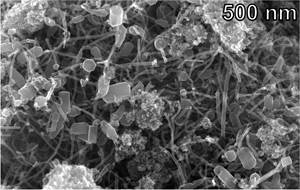

▪ The patented Timeplast additive is a “powerful” solvent created through the proven synthesizing principles of Abiogenesis (informally known as origins of life—this is the natural process by which life has arisen from non-living matter such as simple organic compounds.). This solvent reportedly mimics the two enzymes produced by the Ideonella sakaiensis bacteria, which is able to digest plastic. By reproducing these enzymes chemically, they can be heated without denaturalization.

▪ The Timeplast additive is available commercially but is still undergoing trials in both the U.S. and Europe.

▪ Timeplast is added to the plastic prior to processing. During the manufacturing process the plastic is heated to a melting point, making it malleable. The heat widens the micro space between the isostatic blocs of the plastics polymer chain, much like nature does, but at a much higher degree.

▪ TimePlast alters the molecular chain—breaking the chemical bonds. If this process is not stopped, the plastic will convert into wax.

▪ Nano-degraded plastic is created—the chemical bonds that were broken are substituted with the weaker links created by Timeplast. The end result is a re-engineered, nano-degraded plastic, that has been substantially weakened.

▪ Timeplast can be added to PET, PP, PE, nylon, or other packaging-related thermoplastic without restriction. The end product is composed of 97.79% naturally benign carbon wax, but looks and feels like regular plastic in terms of quality. While indistinguishable from untreated plastic, Timeplast-treated products are more benign to the environment and their biological footprint is far lower.

▪ Timeplast-treated plastic has a 307.5% higher recyclability potential. Such treated plastic reportedly integrates seamlessly into the existing recycling stream, and only loses 1.6% of quality per recycling cycle vs. standard plastic, which loses 79% in quality per recycling cycle, according to the company.

▪ The Timeplast technology reportedly is the only sustainable technology in the history of the American Plastic Recyclers' (APR) Critical Guidance Protocol to pass their battery of tests without issue for PET. The laboratory that performed APR's Critical Guidance Protocol for TimePlast is Plastic Forming Enterprises (PFE), which is one of the only two laboratories that APR recognizes to do their battery of tests.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=300;quality=90)