Product Line Expanded to Include Sprue Bushings and Heated Nozzles

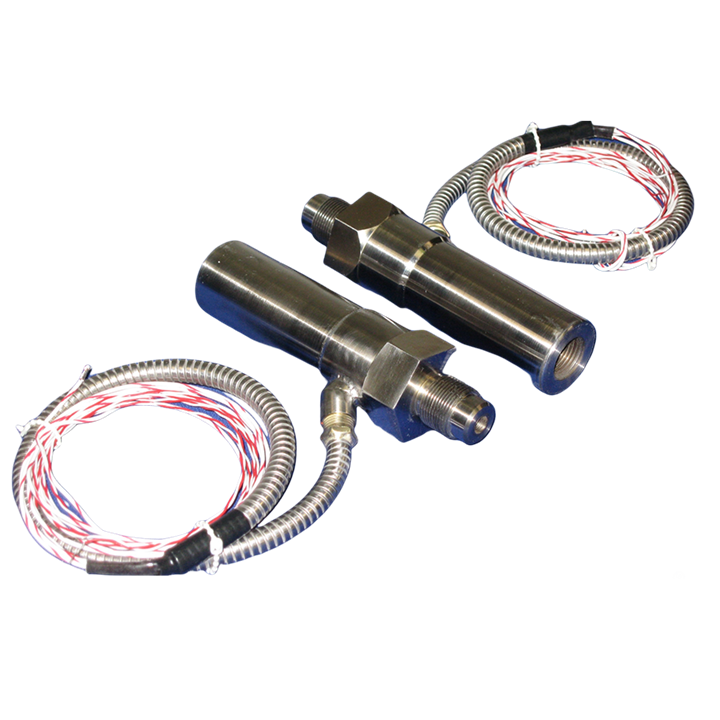

Spark Industries’ offerings now include integrally heated sprue bushings and machine nozzles.

Share

Spark Industries LLC (Elkhart, Ind.) has expanded its product line to include integrally heated sprue bushings and machine nozzles, in addition to its existing portfolio, which includes custom mold boxes; mold and cable diagnostics; cables and the Fast Heat Pulse and Ion hot runner controllers.

Spark notes that integrally heated sprue bushings provide excellent heat transfer and can process a wide range of resins. The bushing’s streamlined flow channel terminates in a reverse taper gate, minimizing pressure loss and allowing for rapid gate freeze. The formation of a small gate stub on the part or runner results in a machine hold-time reduction, with reportedly no increase in sink marks on the molded part. They feature a replaceable type-J thermocouple located close to the flow channel and are available in either a standard .500- or .750-in. radius head or custom as requested. Gate options include a standard sprue for non-machined applications, with extra stock for machining applications, or a euro style extra stock with a reduced gate diameter for use in restrictive areas and those that require less heat loss.

Integrally heated machine nozzles also provide strong heat transfer. With this line, tip options include general purpose for PS, PE and PP; full taper for ABS, PMMA, and polysulfone resins; and a nylon tip for the polyamide and acetal families. Power leads are 90° standard, with an optional 45° or the ability to be customized to the specific machine requirements. Standard thread sizes include: 1.25 in. —12 UNF, 1.5 in. —12 UNF and 1.75 in. —8 UNF. Metric or other sizes are available upon request, and the flow diameters are .500-in. standard or .750-in. end taper to a .500-in. flow channel.

Spark Industries’ heated machine nozzles come in a variety of models, including general purpose and specialized variations for different engineering resins.

Photo Credit: Spark Industries

Related Content

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

.png;maxWidth=300;quality=90)