System Protects Resin from High-Speed Conveying

Processors can easily and automatically select and use capabilities to protect resins from damage caused by dilute-phase conveying systems operating at excessive speeds.

AutoWave is a new feature of Conair’s multi-phase, variable-speed Wave Conveying system. It reportedly makes it easy for processors to automatically select and use capabilities to protect resins from damage caused by dilute-phase conveying systems operating at excessive speeds.

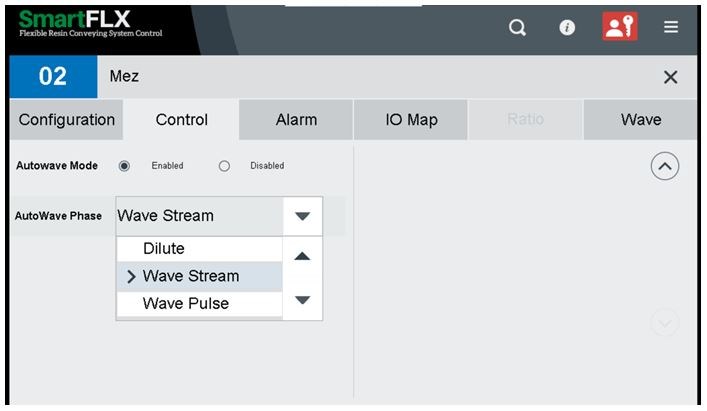

Designed as a “bolt-on” addition to Conair’s SmartFLX control, AutoWave signals the next stage of development for Conair’s Wave Conveying system, the first resin-conveying system to allow use of multiple conveying speeds and phases. Wave Conveying can move resin in dense material “pulses” (Wave Pulse phase); gentle, rolling “streams” (Wave Stream phase); or conventional, but speed-controlled dilute phase.

Wave Conveying was developed to eliminate the problems associated with dilute phase conveying, which moves resin at speeds that are fast enough to damage the resin through friction/rubbing or impact/shattering. This, in turn, results in resin waste, angel hair, and fines, and maintenance problems with clogged filters, overheated pumps, or sluggish conveying performance. Especially when abrasive, filled or reinforced resins are transported at high speeds, tubing elbows and some receiver parts can easily wear to the point of failure. There are a number of ways to compensate for these problems but Wave Conveying actually can eliminate them.

Until now, however, users had to manually program a series of parameters—a conveying recipe—into the conveying control for each receiver in a conveying system. Then, if the recipe needed refinement, additional manual programming or parameter changes would be required.

Nick Paradiso, Conair’s conveying products manager, says the AutoWave feature eliminates virtually all of that manual programming. “Now, to convey a particular resin, a user needs only to use the new Conair SmartFLX HMI to select a source and destination, then open up a new, simplified receiver control screen and select a desired conveying phase. The AutoWave feature coordinates with the SmartFLX control and Wave Conveying components to complete the job”

To keep each conveying cycle “in phase,” AutoWave relies on logic and processing power housed in a supplemental PLC, which links to the same high-speed PowerLink network that is shared by the SmartFLX conveying control and all primary conveying equipment. In operation, the AutoWave PLC constantly monitors inputs from Wave Conveying sensors and components; processes them through intelligent conveying algorithms; then, if needed, adjusts the conveying cycle in real-time to assure “in-phase” performance. Because AutoWave continually logs (and references) the real-time adjustments it is making, every conveying solution is optimized with continued use.

Related Content

-

Automated Resin Management and Blending System for Tight Spaces

NPE2024: Designed for new and existing operations with up to 10 machines and limited available space.

-

Cut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

-

Mobile Sanitary IBC Unloading and Conveying System

Transfers contamination-sensitive bulk solid materials from IBCs to downstream processes, dust-free.