Tooling: New Mold Components at Fakuma Show

Automatic safety locks, mold status indicators, hose manifold blocks, online ejector configurators, and new flexible lifters.

Three suppliers of standard mold components showed off additions to their lines at October’s Fakuma 2018 show in Germany. A handful of new components from Hasco includes safety couplings (Z80700HT to Z80801HT) with an automatic safety lock that protects against accidental unlocking, while still ensuring easy decoupling. A deliberate unlocking movement required of the rotating guide on the locking sleeve, and a clearly visible green color coding behind the locking sleeve indicates correct and safe coupling.

Another introduction is Hasco’s A5850 mold status indicator, which can be attached to a mold by screws or magnet. A knurled wheel allows changing a color indicting band, without tools. Four colors indicate whether a mold is ready for use, needs maintenance, is ready for sampling, or is out of service.

New Z21 centering sleeves are said to be a simple and flexible means to precisely align plates on injection molds as they are joined together. Hasco notes the sleeve’s space-saving position above the buildup screw connection, which is further facilitated by a 15° lead-in chamfer.

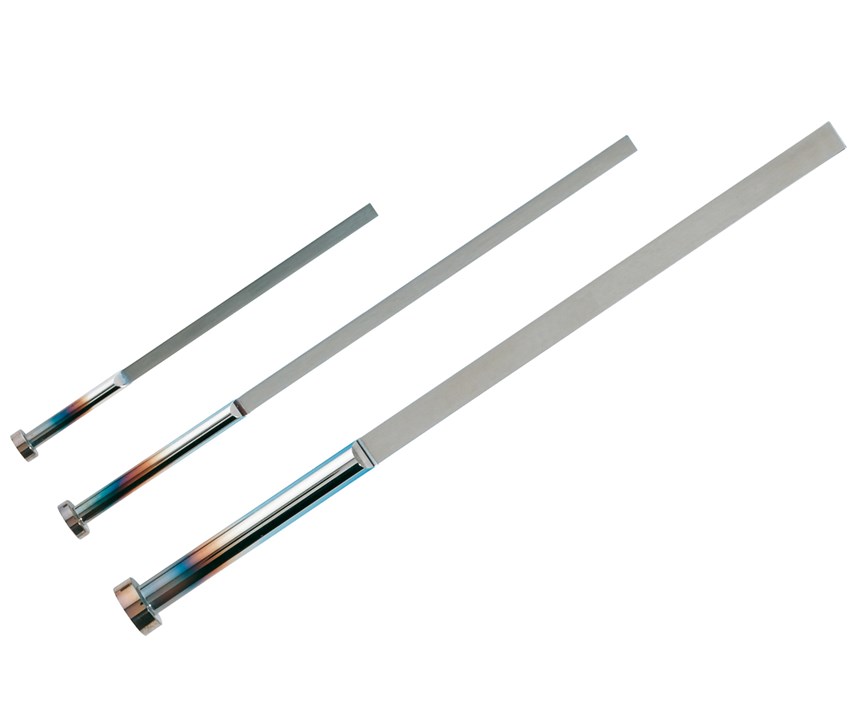

Other new Hasco products include Z2302 positive locking cylinders for valves and cores, with mechanical end-position detection and suited for use at up to 180 C/356 F. New Z920 manifold blocks allow simple configuration of flexible cooling hoses with a clear arrangement of feed and return lines. The new Z086 flat locating unit for high-precision molds supplements conventional guide pillars and bushings. New flat ejector pins have extra blade length and either no corner radius (Z4670) or four corner radii (Z4671). Mold plates are now available in a pre-hardened steel, 1.2714HH. With a maximum hardness of 400 HB, it offers good machinability, dimensional stability and toughness while requiring no additional heat treatment.

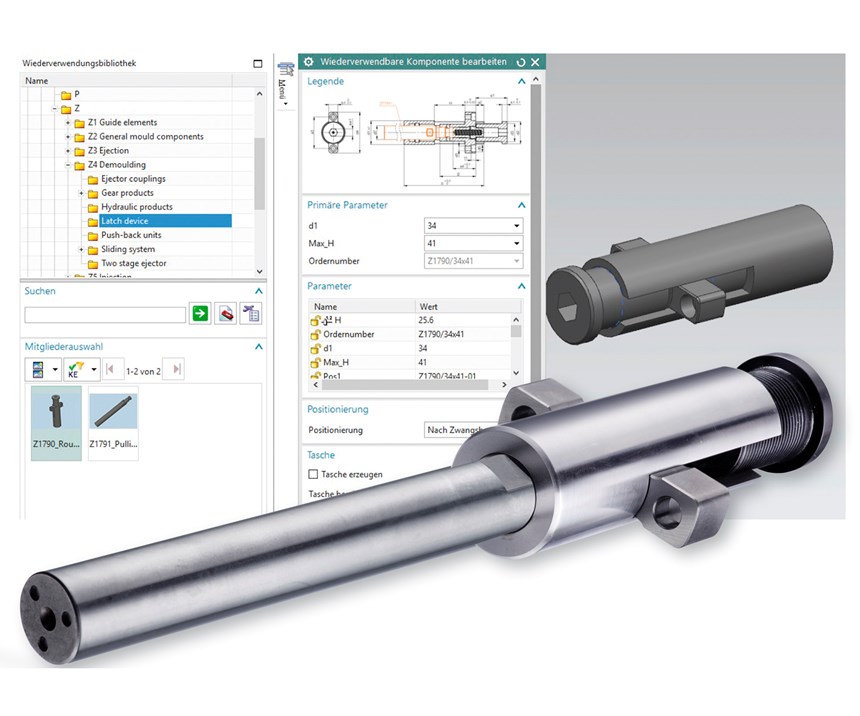

And when it comes to configuring tooling on a computer, Hasco customers now have direct access to the Hasco NX library of native CAD data in Siemens NX format. Downloading the entire library allows design by drag-and-drop and makes it much easier to switch components than if users had to download individual products one by one.

Meanwhile, Meusburger has introduced a new online custom ejector configurating and ordering capability. Among many new components available now in stainless-steel are safety couplers, quick couplers, and vent valves. The company also brought out DLC-coated guide plates, larger tunnel-gate inserts, and additional sizes of guide pillars (standard and DLC coated), as well as a range of non-metric “USA System” components. New E 1675/1676 sprue adjusters are round plugs for blocking off cavities; accessible from the split-line face, they can be rotated with a hex wrench to open or close off runner channels.

The latest in undercut-release components from CUMSA are new flexible lifters consisting of a jacketed steel coiled cable. They allow angles up to 6°, while CUMSA’s rigid, double-rack lifters cannot go below 8°. The smaller Smart Worm Pin is suited to ejector strokes of 30 or 60 mm and undercuts up to 6.3-6.4 mm. The larger Smart Worm Lifter is sized for 100- or 125-mm ejector strokes and up to 145-mm undercuts.

Related Content

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreMachine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as well as advanced control platforms.

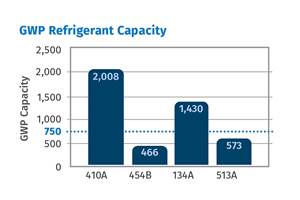

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreWisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More

.png;maxWidth=300;quality=90)