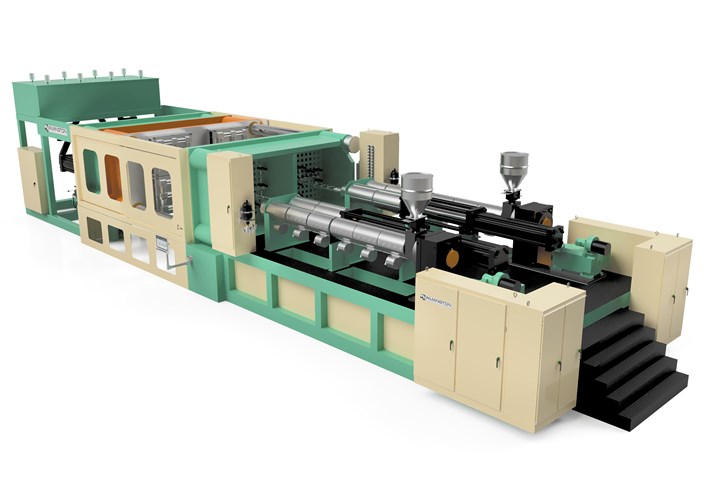

Upgraded Low-Pressure Foam Presses With Elevated Bases

Updating low-pressure horizontal foam-molding presses with elevated bases.

Wilmington Machinery has completely redesigned its HE (horizontal elevated) series of low-pressure foam molding machines to incorporate all the features—and more—that are available on the company’s low-profile models. The elevated presses provide for both robotic and below-the-press product removal. Space beneath the press also provides the clearance necessary for large molds with vertical core movements. And the elevated injection unit provides for a raised deck for ease of setup of nozzle/manifold components in applications for classic low-pressure structural foam, gas assist or gas counterpressure molding.

The new machines come in 750, 1000 and 1500 tons. Both single and dual injectors of reciprocating or two-stage extruder/accumulator format are available with 75- to 300-lb shot capacity and melting capacity of 1500 to 6000 lb/hr. Versafil controls handle basic temperatures, press motion and injection velocity/pressure, as well as remote troubleshooting, SPC charting, trend analysis, graphing and integrated auxiliary control. Versafil control is standard for classic multi-nozzle structural-foam molding and is adaptable to hot-runner injection.

Related Content

-

Structural Foam Injection Molding Line Extended

At K 2022, Wilmington Machinery introduced the dual-injection Lumina MP1200 medium pressure molding machine.

-

Internal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

-

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.