‘Universal’ Structural Foam Nozzles And Manifold Components

Wilmington now provides these components for all makes of structural-foam machines.

For the first time, Wilmington Machinery is now offering structural-foam nozzles and manifold components that are said to be “universal” for all structural-foam machines of any make. Previously, the company offered such components only for its own machines. The new Lumina products, all manufactured in-house, are available on the company’s website and sold as assemblies or individual components.

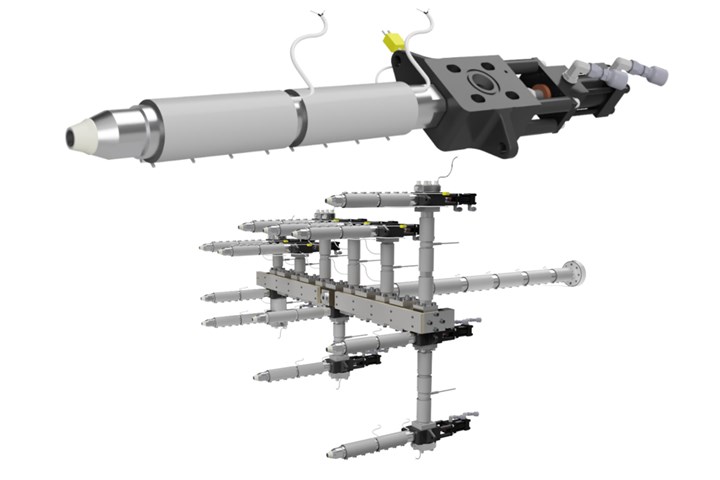

The Lumina nozzle has a forged body with what are described as “generous flow characteristics” and variable nozzle length extensions. The forged nozzle housing is said to provide improved plastic flow compared with other nozzle types. It also reportedly costs less than comparable nozzles. The Lumina manifolds are provided with block-off plug provision to eliminate stagnant melt buildup. Spacers (manifold extensions) are available in various lengths to match the 6 × 6 in. grid pattern for nozzle placement.

Related Content

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

-

Moving Beyond the Relative Viscosity Curve — Determining Optimum Plastic Flow Rates: Part 1

Should injection molders consider using a range of plastic flow rates, versus the selection of one plastic flow rate from the relative viscosity curve?

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.