Feeding & Blending

AEC Extends Warranty on BD Series Blender

Coverage extended from previous term of one year.

Read MoreLoaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

Read MoreBlenders Now Come with Brushless Motors

NPE2024: New, more compact units deliver more efficiency, greater feed capacity, and next to no maintenance requirements.

Read MoreContinuous Mixer Supports Mechanical and Chemical Recycling Applications

NPE2024: Recycling solution works for a variety of situations including pyrolysis.

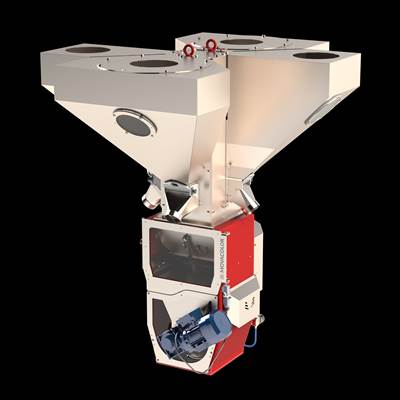

Read MoreBlender Built for Hard-to-Handle Materials

NPE2024: New series targets application using recycled materials. Quick-change feeder also debuts.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreHigh-Performance, Cost-Effective Volumetric Feeder

New unit can handle a wide range of materials in various forms.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Watch (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)