Continuous Mixer Supports Mechanical and Chemical Recycling Applications

NPE2024: Recycling solution works for a variety of situations including pyrolysis.

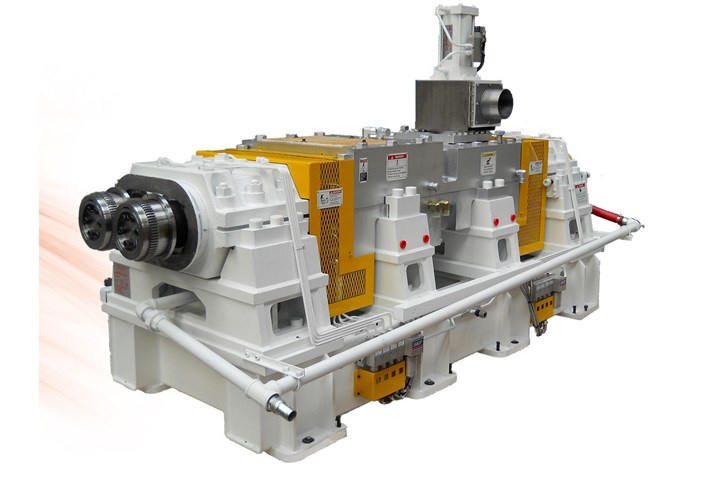

Farrel Pomini will display a product for both mechanical and chemical recycling systems, the Farrel Continuous Mixer.

The mechanical recycling system features include a large feed hopper for ingestion of irregularly shaped material, crammer options for low bulk density feeding, hard surface coatings for maximum wear, a grooved mixer feed section and a vent capture system.

The Farrel Pomini Continuous Mixer. Source: Farrel Pomini

Mechanical recycling on the Farrel Continuous Mixer is achieved with similar energy efficiencies of other applications at nominal production rates, according to the company.

As a complete recycling solution, the Farrel Continuous Mixer also serves as the primary stage of the chemical recycling process of pyrolysis to heat and melt plastic or rubber. Farrel pomini is a partner with WF Recycle Tech, which has a patented pyrolysis system for recycling end-of-life tires.

In addition, a presentation will be given showcasing Farrel Pomini’s role in a pyrolysis process for plastics developed by Lummus Technology. The process takes streams of different postindustrial and postconsumer waste to sort, shred, clean and prepare for a downstream conversion reactor for pyrolysis. The Farrel Continuous Mixer is utilized to melt the feedstock resin and homogenize it under specific temperature and pressure parameters.

Farrel Pomini will also be highlighting capabilities in biodegradable plastics and recycled compounding at NPE. The Farrel Continuous Mixer’s low process temperature, short residence time and efficient rotor shear are useful for processing temperature-sensitive or prior heat-history applications. Successful experience processing PLA, PHA, PBS as well as recycled PVC and film scrap will be featured.

Dr. Peng Ye, applications development manager for Farrel Pomini, will present, “Novel Biocomposites Produced by the Continuous Compounding Process.” The presentation will cover work among partners Farrel Pomini, FPInnovations, West Fraser and Good Natured Products, to develop biobased and compostable compounds by combining wood-based and biopolymer materials.

Related Content

-

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

-

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

-

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.