scientific molding

Moving Beyond the Relative Viscosity Curve — Determining Optimum Plastic Flow Rates: Part 3

Molders can use data to determine optimum flow rates by combining cavity imbalance studies with an understanding of machine velocity capabilities.

Read MoreMoving Beyond the Relative Viscosity Curve — New Method To Find Optimum Plastic Flow Rates: Part 2

Explore the use of the injection unit velocity capability, which determines a machine’s injection speed linearity to find optimum flow rates, and proposes a second method.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreOnline Versions of Process Development Course and Software Launch

NPE2024: FimmTech is introducing online versions of its Nautilus process development software as well as its Scientific Molding and Design of Experiments (DOE) process development course.

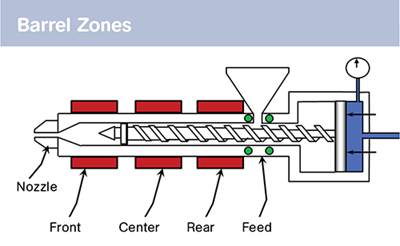

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

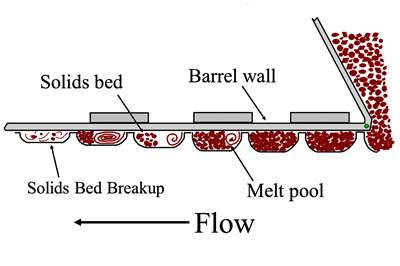

Read MoreImprove Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

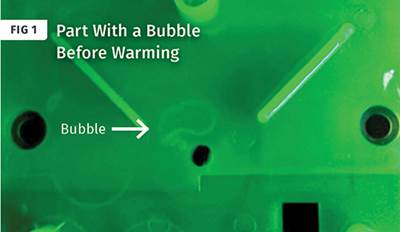

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

Read More