Additive Manufacturing: Through the Molders’ Lens

Many in the manufacturing world experienced first-hand how agile and efficient 3D printing is when companies began to print products to combat the COVID-19 pandemic. Custom molder EVCO expanded its 3D printing capabilities during this time to help produce parts quickly.

Share

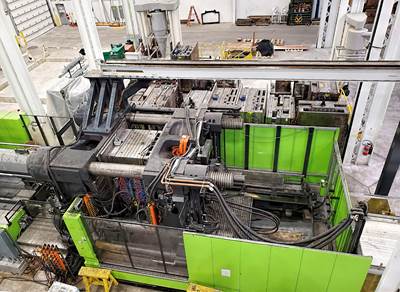

EVCO’s print farm is serviced by a Universal Robots collaborative robot, which allows the 3D print farm to run 24/7 production.

Custom injection molder EVCO Plastics sees a bright future for additive manufacturing. EVCO has nine plants and 210 machines devoted to a wide range of markets. At its headquarters in DeForest, Wis., the company uses 3D printing side by side with normal production.

EVCO first added a MarkForged Mark One 3D printer back in 2014. The company currently has 14 printers, 12 of which are part of the print farm and the other two operate independently. Of the 12, one of them is a Mark 2 series and the rest are Onyx 1 series. The Mark 2 allows EVCO to feed an additive fiber for harder surfaces. The 3D print farm is serviced by a Universal Robots collaborative robot, which allows the print farm to run 24/7 production.

“There is a large advantage with the cost savings and time to fabricate components using the 3D printers,” notes Jason Glanzer, automation engineer for EVCO.

The MarkForged technology uses CFF (Composite Filament Fabrication) in combination with standard FFF (Fused Filament Fabrication). This technique produces fiber-reinforced composite parts, which are up to 20 times stiffer and five times stronger than parts printed using plastic. Designers can choose among Kevlar, carbon fiber and fiberglass to reinforce a specially formulated nylon, which makes the parts stiff and strong.

“With the new line they released features for more of an industrial interface that interacts with other equipment like the robots,” says Glanzer. “We exchange quite a bit of information with them on the interface.”

EVCO added six new printers in 2020 to help streamline automation and to answer the call for a big influx of 3D printed parts.

The 3D printers produce fixtures for metrology, prototype molds, robot grippers, sensor mounts, part nests or fixturing, EOAT (end of arm tooling), R&D and, now, commercial production. Glanzer says that with 3D printing, EVCO can save time to produce several parts while personnel are also focused on production runs.

COVID Impact

Many in the manufacturing world experienced first-hand how agile and efficient 3D printing is when companies began to print products to combat the COVID-19 pandemic. At EVCO, the company expanded its 3D printing capabilities to help produce parts quickly.

“It changed everything—from our timelines on what needed to be built, to everything needing to be done in the quickest way possible,” Glanzer recalls. “We are usually able to shave a week or two off to fabricate a component using 3D printing as opposed to machining aluminum.”

The company added six new printers in 2020 to help streamline automation and to answer the call for a big influx of 3D printed parts.

Anna Bartz, EVCO’s director of communications, says the company has manufactured several components related to COVID-19 testing, including a saliva-based coronavirus test kit that is produced 24/7 in a five-machine cell with automated assembly, filling, sealing, weighing, labeling and packaging in a thermoformed tray. EVCO’s printer “farm” allows for expedited turnaround on new project startups.

“Speed wins and saves lives,” she says. “In this case, 3D printing allows those product lines to scale up quickly. We have around 20 machines running 24/7 on COVID-related products, and that certainly didn’t happen overnight. But we were able to link up with automation and get those products to scale up much quicker.”

The aggressive timelines set by demands for COVID-19 testing kits meant the company needed to quickly build and implement robotics for handling the automation. EVCO keeps production lines running by replacing basic broken components with 3D printed parts. The larger picture on cost savings is the reduced machine downtime.

“If something goes down, due to a broken bracket or broken component, we can get it up and running within hours as oppose to waiting a day or two, which is another huge cost saver,” Glanzer points out.

Later this year, the company expects to add a metal 3D printer to the printer farm.

Related Content

-

KraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Related Content

KraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read MoreRead Next

More Milestones for EVCO Plastics

Custom injection molder is adding floorspace, machine capacity, and contract manufacturing capabilities at multiple plants in the U.S. and Mexico.

Read MoreEVCO Plastics Gears Up To Mold Coronavirus Test Kits

The firm has added shifts, reassigned people and injection machines—and is buying new ones—in a crash program to mold and assemble COVID-19 test kits.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More